10 Years PCB & PCBA Factory, PCB SMT DIP Electronic Components Assembly

Files and Requirment for PCB,PCBA quotation

· A BOM (Bill of Materials) with reference designators: component description, manufacturer’s name and part number.

· PCB Gerber files.

· A PCB fabrication drawing and PCBA assembly drawing.

· Test procedures.

· Any mechanical restrictions such as assembly height requirements

· PCB board PCBA service:

o o Components sourcing

o o PCB assembly

o o Function test

o o One stop service from PCB components sourcing, PCB assembly, test, packing and PCB delivery

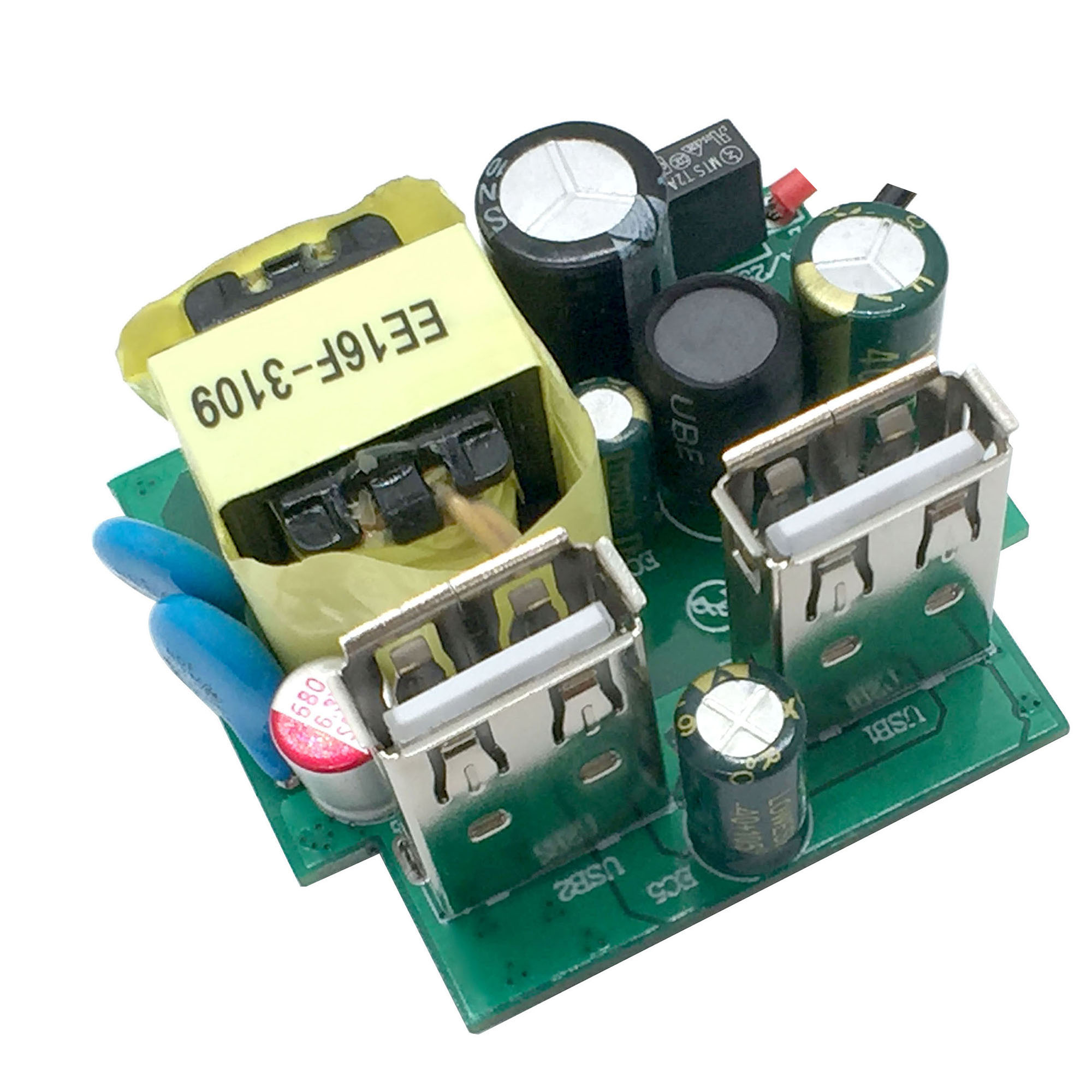

Turnkey PCBA services

- Components sourcing

- PCB assembly

- IC programming

- Functional testing

PCB Assembly Production range

· PCB Assembly with SMT Technology, Turnkey Projects and Die Bonding Process, Lead-free

· FR4 standard PCB from 2 ~ 24 Layers, expecially applicated for Industry control and Telecommunication area.

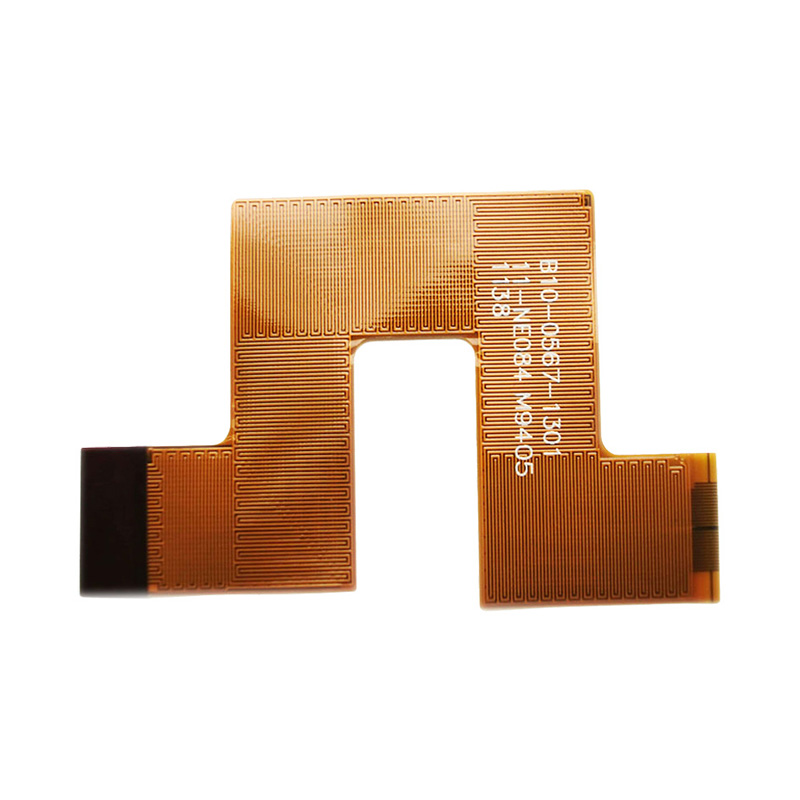

· Rigid flexible PCB from 1 ~ 6 Layers

· LED / Aluminium PCB

Technical requirement

1.Professional Surface-mounting and Through-hole soldering Technology

2.Various sizes like precision 0201,0402, 0603, 0805, 1210 and 2512 components SMT technology

3.ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4.PCBA Assembly With CE, Reach, Rohs Approval

5.Nitrogen gas reflow soldering technology for SMT.

6.High Standard SMT & Solder Assembly Line

7.High density interconnected board placement technology capacity.

What shall we do ?

Our mission states that lmo excellent engineering, automation and test, and manufacturing capabilities will deliver industry-leading value to our stakeholders by transforming technology and concepts into innovative and successful customer solutions. To realize our vision and mission, and achieve customer loyalty, we build long-term relationships with our customers for mutual success. Valuing the diverse talents of each employee, we contribute to your project in an atmosphere of teamwork, empowerment, and recognition. To enhance customer success and profitability we use the latest technology, supply chain, information and quality management systems. lmo exceeds the quality expectations of its customers by continuously improving systems and processes.