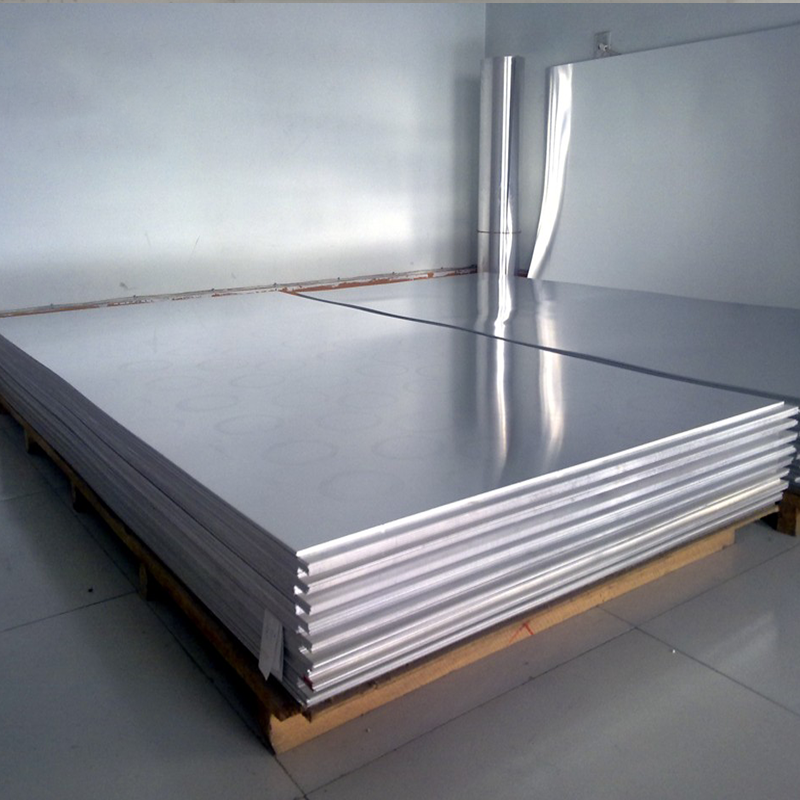

1100 3003 5052 6061 5mm Polished Aluminum Alloy Sheet Plate For Building Decoration

Product Detail

Aluminum plate refers to a rectangular plate rolled from aluminum ingots. It is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium-thick aluminum plate and patterned aluminum plate.

SPECIFICATIONS FOR ALUMINUM PLATE

| Place of Origin | Tianjin, China |

| Delivery Time | 8-14 days |

| Temper | H112 |

| Type | Plate |

| Application | Tray,Road traffic signs |

| Width | ≤2000mm |

| Surface Treatment | Coated |

| Alloy Or Not | Is Alloy |

| Model Number | 5083 |

| Processing Service | Bending, Decoiling, Punching, Cutting |

| Material | 1050/1060/1070/1100/3003/5052/5083/6061/6063 |

| Certification | ISO |

| Tensile strength | 110-136 |

| yield strength | ≥110 |

| elongation | ≥20 |

| Annealing temperature | 415℃ |

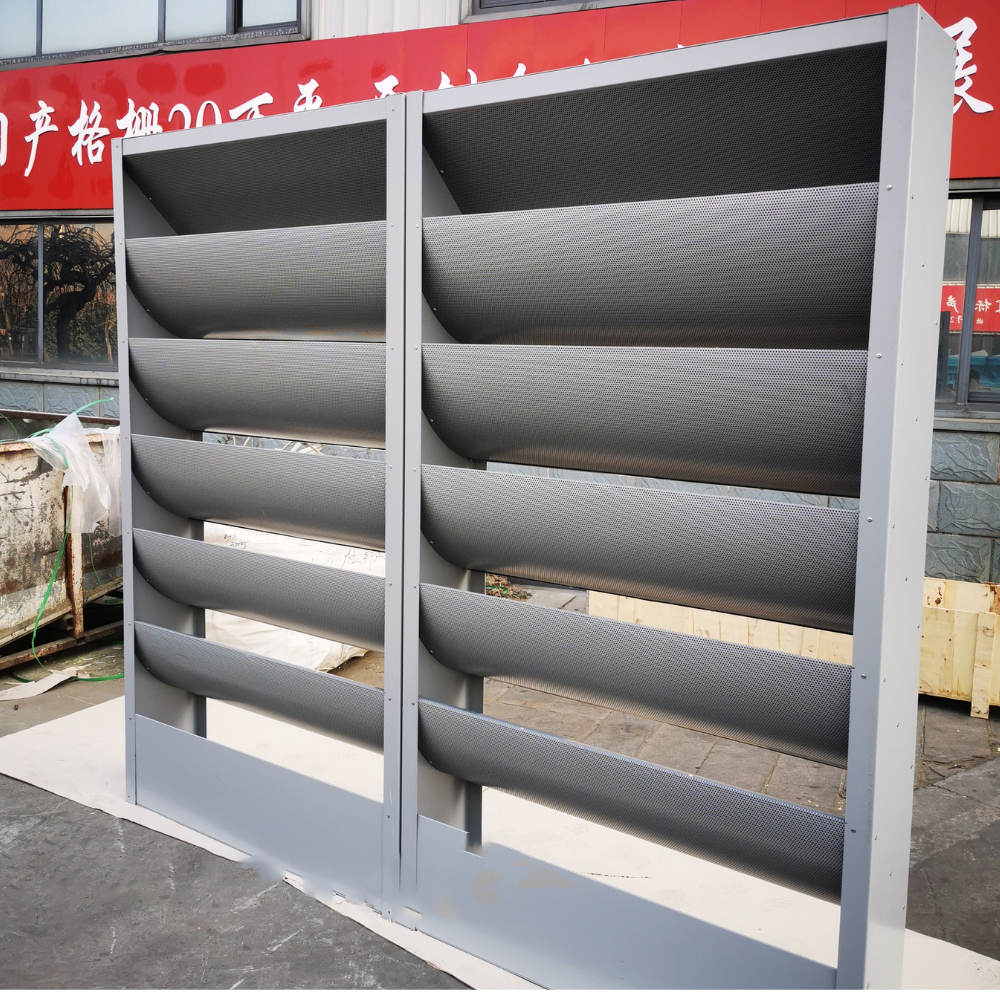

SPECIFIC APPLICATION

1.1000 series aluminum plate refers to aluminum plate with a purity of 99.99%. Common varieties include 1050, 1060, 1070 and so on. 1000 series aluminum plates have good processability, corrosion resistance and electrical conductivity, and are often used to manufacture kitchenware, chemical equipment, industrial parts, etc.

2. 3000 series aluminum plates mainly refer to 3003 and 3104 aluminum plates, which have good corrosion resistance, weldability and formability, and are often used to manufacture body panels, fuel tanks, tanks, etc.

3. 5000 series aluminum plates usually refer to 5052, 5083 and 5754 aluminum plates. They have high strength, corrosion resistance and weldability, and are often used to manufacture ships, chemical equipment, car bodies and aircraft parts.

4. Common 6000 series aluminum plates include 6061, 6063 and other varieties. They have the characteristics of high strength, corrosion resistance and weldability, and are widely used in aerospace, flexible moment components, lighting, building structures and other fields.

5. 7000 series aluminum plate mainly refers to 7075 aluminum plate, which has the characteristics of high strength, light weight and good heat resistance. It is often used to manufacture parts with high strength requirements such as aviation fuselages, rudder surfaces, and wings.

Packaging & Shipping

Packaging:

1.Packaging materials: Common packaging materials can choose plastic film, cartons or wooden boxes.

2.Size: Choose the appropriate size according to the size and quantity of the aluminum plates, and ensure that the aluminum plates have enough space inside the package to avoid damage during transportation.

3.Jumping cotton: Jumping cotton can be added to the surface and edges of the aluminum plate to avoid damage caused by scratches or impacts.

4. Sealing: Plastic film packaging can be sealed with heat sealing or tape to increase airtightness, and carton or wooden box packaging can be sealed with tape, wooden strips or steel strips.

5. Marking: Mark the specifications, quantity, weight and other information of the aluminum plates on the packaging, as well as fragile signs or special warning signs so that people can handle and transport the aluminum plates correctly.

6. Stacking: When stacking, the aluminum plates should be stacked and supported appropriately according to their weight and stability to avoid collapse and deformation.

7. Storage: When storing, avoid direct sunlight and high humidity to prevent the aluminum plate from getting damp or oxidized.

Shipping:

Standard export sea-wort packaging, in bundles, wooden case or as your requirements