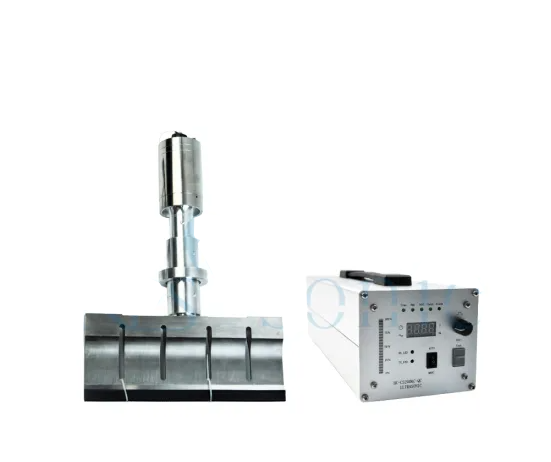

20Khz 1000w ultrasonic food cutting machine with titanium blade

20Khz 1000w ultrasonic food cutting machine with titanium blade

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

The trendsetting cutting technology

In many industries intelligent ultrasonic cutting established itself as the preferred method for clean and fast separation without any waste. Scoring or cutting of food items like dough, cheese and meat, or separating of materials like fleece, carpet, foam, rubber, light-weight materials, foil, or textiles without fraying or unraveling, the Industry 4.0-ready ultrasonic technology is the right tool for you. This process provides another advantage: The combination of cutting and welding seals the edges in the same process step.

Broad range of applications

Process safety, reproducible results, and time savings gained by the speed of the process are only some of the advantages you can gain by employing ultrasonic technology. Depending on your individual requirements we offer vertical or horizontal cutting solutions which can be realized as continuous cut or in a cycle mode.

Cutting systems by RPS-SONIC Ultrasonic are specifically tuned to the individual characteristics and consistency of the material, e.g. cheese, lunch meat or dough. Even warm, fresh, sticky or frozen food can be separated, scored or cut in smaller pieces with ultrasound. Your hugh advantage: The need to stop at the blade can be almost completely eliminated with the use of ultrasound which keeps the edges especially clean.

Durable, low in maintenance and flexible

Compared to mechanical blades, cutting Sonotrodes stay sharp longer and require much less maintenance. In conjunction with our flange converters, a tool change with cutting Sonotrodes is a breeze. This is how RPS-SONIC keeps your production going.

Ultrasonic food processing involves a vibrating knife (guillotine) producing a nearly frictionless surface that minimizes buildup on the blade surface. The ultrasonic blades cleanly cuts sticky products and inclusions such as nuts, raisins & morsels without displacement. Ultrasonic cutting is used by many of the world’s largest and most prestigious food producers.

ADVANTAGES

Precise separation with almost no loss of material

Cutting of frozen goods

No fraying on edges

High degree of process safety

Reproducible results

Cutting cycles or continuous cutting possible

Little tool wear

Simultaneous cutting and sealing possible

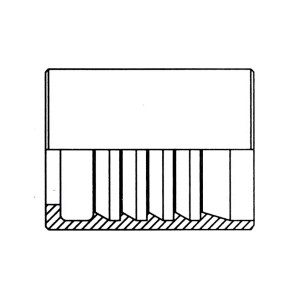

Our Sonotrodes are always designed for a specific customer or application using FEM (finite elements method). Usually made from Titanium, we manufacture the correctly shaped blade like arrow heads, sickles, punch or X-Sonotrodes, for each application. For ultrasonic punch applications, we also provide the matching die or counter piece to each punch Sonotrode.

Pictures