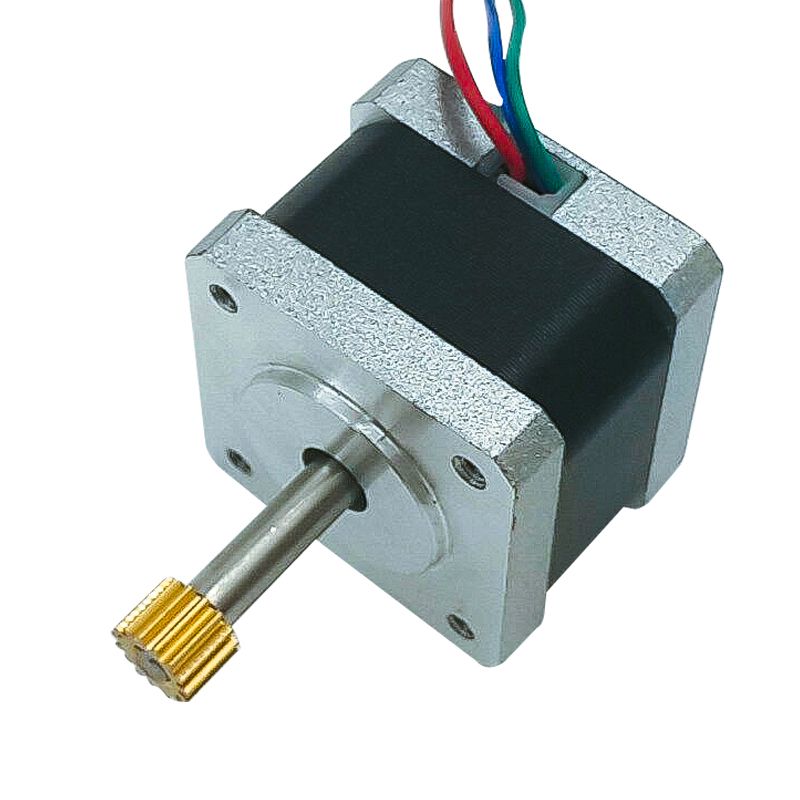

24BYJ Permanent Magnet Geared Stepper Motors

Technique Parameter

| Item | Specification |

| Step angle Accuracy | ±10% (fullstep ,no load) |

| Resistance Accuracy | ±10% |

| Temoerature Rise | 60℃.(rated current,2 phase on) |

| Ambient Temperature | -10℃~+40℃ |

| Insulation Resistance | 100MΩ Min. ,500VDC |

| Dielectric Resistance | 600VAC , 1s , 1mA |

| Shaft Radial Play | 0.05mmMax |

| Shaft Axial play | 0.55mmMax |

Product Description

The permanent magnet deceleration stepper motor is a type of motor that combines the advantages of a permanent magnet motor and a stepper motor. It is widely used in various industries due to its unique composition and excellent performance.

This motor consists of several essential components, including a permanent magnet rotor, a stator, a deceleration mechanism, and a control system. The permanent magnet rotor is a key element that generates the magnetic field required for the motor’s operation. It is composed of a series of permanent magnets with alternating polarities, which create a rotating magnetic field when energized. The stator, on the other hand, houses the windings that produce electromagnetic fields to interact with the rotor’s magnetic field. The deceleration mechanism, such as a gear system or a belt drive, is responsible for reducing the motor’s speed and increasing its torque. Lastly, the control system regulates the motor’s operation by providing precise electrical pulses to the windings, enabling accurate positioning and control.

1. The trapezoidal claw pole of stepper motors is stamped and extended, making it easy to manufacture and process;

2. The trapezoidal claw pole design is suitable for multi-pole structures, which not only reduces the step angle of the permanent magnet stepper motor, but also has high material utilization rate;

3. Since the number of claw pole teeth is equal to the number of rotor poles, the tooth harmonic torque is the second harmonic torque, and the two stators are offset from each other by 90° electrical angle, so the tooth harmonic torque amplitude of the two stators is equal and the phase is opposite. The result is zero.

Importance of its application areas

Industrial Automation

A. Use in robotics and automated machinery

B. Advantages over other types of motors

Medical Equipment

A. Role in precision medical devices

B. Benefits in terms of accuracy and reliability

Automotive Industry

A. Integration in electric vehicles

B. Contribution to energy efficiency and performance

Consumer Electronics

A. Implementation in printers and scanners

B. Enhancing product functionality and user experience

Remark

1. Coil resistance, phase number and other electrical performance parameters can be customized according to customer requirements;

2. The installation size, output shaft size, output synchronous pulley or output gear, lead length, and plug specifications can be customized according to customer requirements;

Technique Specification

| Model | Voltage(V) | No.of Phase | Resistance(Ω) | Step Angle(DEG) | Rating Ratio | Starting Frequency(pps) | Pulling Torque (300P.P.S) (mN.m) |

Detent Torque(mN.m) |

| 24BYJ28-N05U- | 8 | 2 | 50 | 11.25/16 | 1:16 | ≥500 | ≥24.5 | ≥12.7 |

| 24BYJ28-N05U- | 8 | 2 | 50 | 5.625/16 | 1:16 | ≥900 | ≥34.3 | ≥12.7 |

| 24BYJ28-N08U- | 12 | 2 | 80 | 11.25/16 | 1:16 | ≥500 | ≥24.5 | ≥12.7 |

| 24BYJ28-N08U- | 12 | 2 | 80 | 5.625/16 | 1:16 | ≥900 | ≥34.3 | ≥12.7 |

| 24BYJ48-N05U- | 12 | 4 | 50 | 5.625/16 | 1:16 | ≥1000 | ≥24.5 | ≥12.7 |

| 24BYJ48-N08U- | 12 | 4 | 80 | 5.625/16 | 1:16 | ≥800 | ≥19.6 | ≥12.7 |

| 24BYJ48-012U- | 12 | 4 | 120 | 5.625/16 | 1:16 | ≥700 | ≥14.7 | ≥12.7 |

| 24BYJ48-015U- | 12 | 4 | 150 | 5.625/16 | 1:16 | ≥650 | ≥9.8 | ≥12.7 |

| 24BYJ48-02U- | 12 | 4 | 200 | 5.625/16 | 1:16 | ≥600 | ≥7.84 | ≥12.7 |

| 24BYJ48Z-B31-N02W- | 5 | 4 | 20 | 5.625/25 | 1:25 | ≥800 | ≥19.6 | ≥19.6 |

| 24BYJ28Z-B31-N05W- | 12 | 2 | 50 | 5.625/25 | 1:25 | ≥1200 | ≥49 | ≥19.6 |

| 24BYJ28Z-B31-N08W- | 12 | 2 | 80 | 5.625/25 | 1:25 | ≥1000 | ≥39.2 | ≥19.6 |

| 24BYJ48Z-B31-N05W- | 12 | 4 | 50 | 5.625/25 | 1:25 | ≥1000 | ≥39.2 | ≥19.6 |

| 24BYJ48Z-B31-N08W- | 12 | 4 | 80 | 5.625/25 | 1:25 | ≥800 | ≥19.6 | ≥19.6 |

| 24BYJ28-25- | 5 | 2 | 25 | 5.625/64 | 1:64 | ≥900 | ≥49 | ≥49 |

| 24BYJ28-N08- | 12 | 2 | 80 | 5.625/64 | 1:64 | ≥1200 | ≥49 | ≥49 |

| 24BYJ48-N02- | 5 | 4 | 20 | 5.625/64 | 1:64 | ≥800 | ≥49 | ≥49 |

| 24BYJ48-N08- | 12 | 4 | 80 | 5.625/64 | 1:64 | ≥1000 | ≥49 | ≥49 |

| 24BYJ48-012- | 12 | 4 | 120 | 5.625/64 | 1:64 | ≥700 | ≥39.2 | ≥49 |

| 24BYJ48-015- | 12 | 4 | 150 | 5.625/64 | 1:64 | ≥650 | ≥34.3 | ≥49 |

| 24BYJ48-02- | 12 | 4 | 200 | 5.625/64 | 1:64 | ≥600 | ≥29.4 | ≥49 |

Mechanical Dimensions:mm

Write your message here and send it to us