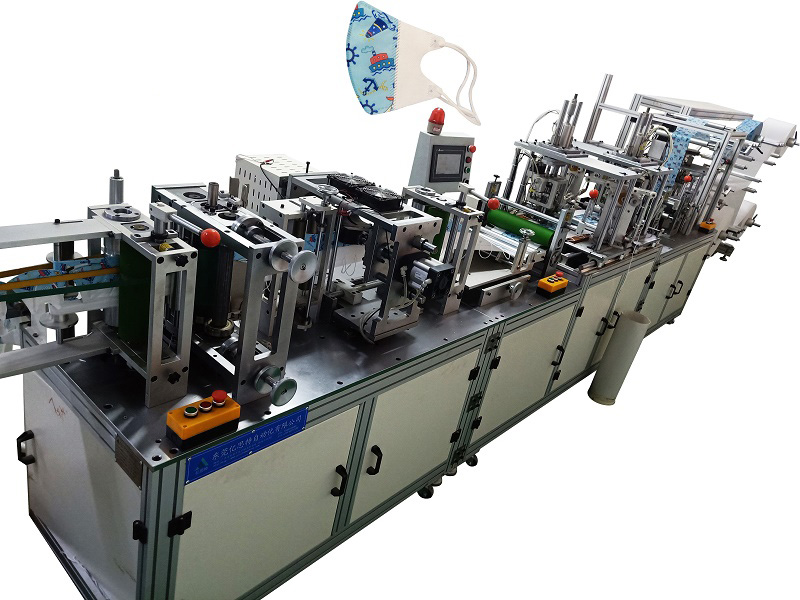

2D automatic child mask machine

| Machine size: | Machine table cloth rack (mm): L2800 X W1200 X H1700 | Machine weight: | 1350kg |

| Back section of the machine(mm): L5000 X W1200 X H1700 | |||

| Power: | 13kw | Control Method: | PLC |

| Yield: | 60-80 slices/min | Detection Method: | Photoelectric Detection |

Full automatic children’s mask all in one machine is a new type of equipment developed for customers to produce cartoon masks. It uses 1 ~ 4 layers of PP spunbonded non-woven fabric, activated carbon and filtration materials as feeding materials. The mask is made by ultrasonic technology. The mask has clear embossing, strong welding and fast speed, which meets the requirements of product performance. The design of the mask strictly conforms to the European and American testing standards, and is fully automatic operation. The whole machine is composed of material frame, forming, welding lug, folding welding and other parts. The automatic children’s mask machine can only produce disposable flat masks, but not N95 and stereo masks.

The mask produced by this equipment can be used as surgical mask as long as it is disinfected. This machine adopts PLC control. The main conveyor belt is transported by single-phase motor, the stepping motor is turned over, the transmission is accurate, the control is stable, and the speed is adjustable.

1, The machine adopts ultrasonic, cutter,welding wheel, and the whole machine has excellent performance.

2, The design concept is mature, which can meet the needs of producing butterfly shaped support mask body.

3, The finished product produced shall have clear embossing, even fold, flat surface and smooth cutting.

4, The equipment operates stably and continuously for a long time, and the product qualification rate reaches 98%.

5, The equipment is fully automatic control, with smooth operation, stable production and no need for human assistance.

6, Simple operation, photoelectric detection.

7, Reasonable design, humanization, less space occupation, reliability and durability.

8 ,Customized process flow according to customer requirements and company logo.

This machine is a fully automated machine for producing folding masks, including automatic feeding and ultrasonic welding. Automatic half-folding, ultrasonic welding bottom, automatic cut-out, automatic waste removal and automatic counting, etc. The entire machine only needs one person to operate and collect the finished product.

1. The automatic operation is simple and efficient.

2. Program computer control, photoelectric detection device, high reliability, stable performance

3. Ultrasonic welding saves time and effort, and is environmentally friendly.

4. The fault self-diagnosis function, the fault display is clear at a glance.

5. Most of the whole machine adopts aluminum alloy structure, high strength, beautiful appearance, not easy to rust