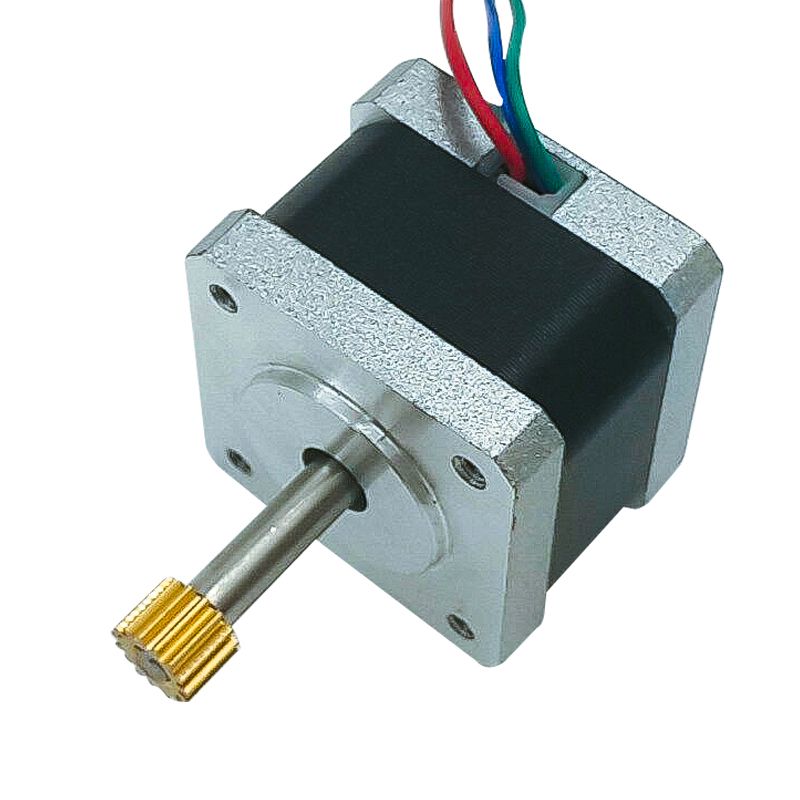

35HS 0.9 Degree Hybrid Stepper Motor

Technique Parameter

|

Item |

Specification |

|

Step angle Accuracy |

±5% (fullstep ,no load) |

|

Resistance Accuracy |

±10% |

|

Inductance Accuracy |

±20% |

|

Temoerature Rise |

80℃.(rated current,2 phase on) |

|

Ambient Temperature |

-40℃~+60℃ |

|

Insulation Resistance |

100MΩ Min. ,500VDC |

|

Dielectric Resistance |

600VAC , 1s , 1mA |

|

Shaft Radial Play |

0.06mmMax (450g-load) |

|

Shaft Axial play |

0.08mmMax (450g-load) |

Product Description

The 35HS 0.9 Degree Hybrid Stepper Motor is a cutting-edge and highly efficient motor that has garnered attention in the industrial and manufacturing sectors. With its precision and reliability, this motor has become a popular choice for a wide range of applications.

One of the key features of the 35HS 0.9 Degree Hybrid Stepper Motor is its high degree of accuracy. The 0.9-degree step angle provides precise control and positioning, making it ideal for applications that require exact movements and positioning. This level of accuracy is crucial in industries such as robotics, CNC machines, 3D printers, and other automated systems where precision is paramount.

Furthermore, the hybrid design of the motor combines the best features of both permanent magnet and variable reluctance stepper motors, resulting in improved performance and efficiency. This design allows for higher torque and smoother operation, making it suitable for heavy-duty applications while also reducing energy consumption.

In addition to its performance, the 35HS 0.9 Degree Hybrid Stepper Motor is also known for its durability and reliability. Constructed with high-quality materials and advanced manufacturing techniques, this motor is designed to withstand harsh operating conditions and provide long-term, trouble-free operation. This reliability is essential for industries where downtime can result in significant financial losses.

Moreover, the motor is designed with easy installation and maintenance in mind, further adding to its appeal. The simple and intuitive design allows for quick integration into existing systems, saving time and resources. Additionally, the low maintenance requirements reduce overall operating costs, making it a cost-effective solution for businesses.

Industrial Applications

- CNC Machines

- 3D Printers

- Robotics

- Medical Equipment

Consumer Applications

- Home Automation

- Automotive Industry

- Aerospace Industry

Advantages of Hybrid Stepper Motors

- High Precision and Accuracy

- Energy Efficient

- Low Maintenance

Remark

1. Coil resistance, phase number and other electrical performance parameters can be customized according to customer requirements;

2. The installation size, output shaft size, output synchronous pulley or output gear, lead length, and plug specifications can be customized according to customer requirements;

Technique Specification

| Model NO. | Rated votage | Current Phase | Resistance Phase | Inductance Phase | Holding Torque | Leads | Rotor Inertia | Weight | Length | ||

| Single Shaft | Double Shaft | V | A | Ω | mH | Oz-in | g-cm | g-cm2 | Kg | mm | |

| 35HS20MF-035A | 35HS20MF-035B | 3.50 | 0.35 | 10.00 | 6.5 | 7.00 | 500.00 | 4.00 | 8.00 | 0.1 | 20 |

| 35HS20MF-08A | 35HS20MF-08B | 10 | 0.8 | 10 | 13.8 | 7 | 500 | 4 | 8 | 0.1 | 20 |

| 35HS26MF-08A | 35HS26MF-08B | 3.8 | 0.8 | 4.8 | 6.4 | 7 | 500 | 4 | 10 | 0.12 | 26 |

| 35HS28MF-03A | 35HS28MF-03B | 7.5 | 0.3 | 25 | 18.0 | 14 | 1000 | 4 | 10 | 0.14 | 28 |

| 35HS28MF-04A | 35HS28MF-04B | 5.0 | 0.4 | 16.8 | 12.0 | 13 | 1200 | 4 | 10 | 0.14 | 28 |

| 35HS28MF-05A | 35HS28MF-05B | 10 | 0.5 | 20 | 24.5 | 14 | 1000 | 4 | 10 | 0.14 | 28 |

| 35HS34MF-04A | 35HS34MF-04B | 10 | 0.4 | 25 | 19.8 | 15 | 1100 | 6 | 14 | 0.17 | 34 |

| 35HS36MF-105A | 35HS36MF-10B | 2.7 | 1.0 | 2.7 | 7.5 | 17 | 1200 | 4 | 14 | 0.18 | 36 |

| 35HS28MF-035ABS | 35HS28MF-035BBS | 12 | 0.35 | 16.8 | 12.0 | 13 | 1200 | 4 | 10 | 0.14 | 28 |

| 35HS28MF035ADL1 | 35HS28MF035BDL1 | 12 | 0.35 | 16.8 | 12.0 | 13 | 1200 | 4 | 10 | 0.14 | 28 |

| 35HS28MF035ADL2 | 35HS28MF035BDL2 | 12 | 0.35 | 16.8 | 12.0 | 13 | 1200 | 4 | 10 | 0.14 | 28 |

| 35HS28MF03ACL | 35HS28MF03BCL | 7.5 | 0.3 | 25 | 18.0 | 13 | 1000 | 4 | 10 | 0.14 | 28 |

| 35HS28MF03ABS | 35HS28MF03BBS | 7.5 | 0.3 | 25 | 18.0 | 13 | 1000 | 4 | 10 | 0.14 | 28 |