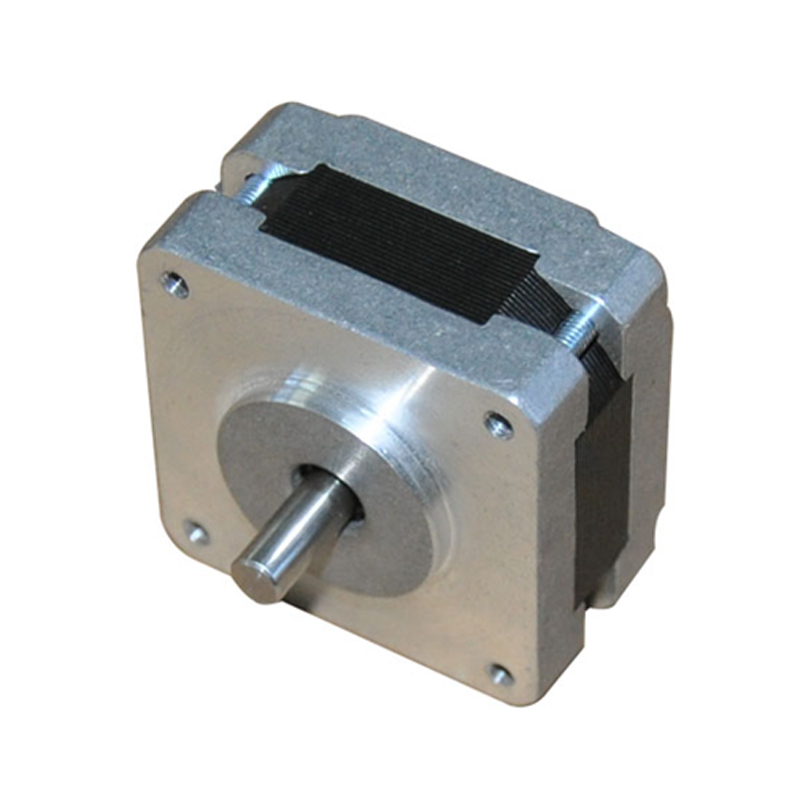

39HS 0.9 Step Angle Hybrid 39mm Stepper Motors

Technique Parameter

| Item | Specification |

| Step angle Accuracy | ±5% (fullstep ,no load) |

| Resistance Accuracy | ±10% |

| Inductance Accuracy | ±20% |

| Temoerature Rise | 80℃.(rated current,2 phase on) |

| Ambient Temperature | -40℃~+60℃ |

| Insulation Resistance | 100MΩ Min. ,500VDC |

| Dielectric Resistance | 600VAC , 1s , 1mA |

| Shaft Radial Play | 0.06mmMax (450g-load) |

| Shaft Axial play | 0.08mmMax (450g-load) |

Product Description

The 39HS 0.9 Step Angle Hybrid 39mm Stepper Motor is a cutting-edge piece of technology that has revolutionized the world of automation and robotics. With its high precision and reliability, this stepper motor has become a popular choice for a wide range of applications, from 3D printers to CNC machines.

One of the key features of the 39HS stepper motor is its 0.9-degree step angle, which allows for incredibly precise control of movement. This level of precision is essential for applications that require accurate positioning, such as in the field of robotics and automation. The motor’s hybrid design also ensures a high level of torque, making it suitable for applications that require a significant amount of power.

In addition to its technical capabilities, the 39HS stepper motor also boasts a compact 39mm size, making it easy to integrate into a variety of different systems. This versatility has made it a popular choice among engineers and designers who are looking for a reliable and efficient motor for their projects.

Furthermore, the 39HS stepper motor is known for its durability and long lifespan. This is due to the high-quality materials and manufacturing processes used in its construction, which ensure that it can withstand the rigors of continuous use in demanding environments.

The 39HS 0.9 Step Angle Hybrid 39mm Stepper Motor is a highly advanced and reliable piece of technology that has found widespread use in the field of automation and robotics. Its precision, power, and durability make it an ideal choice for a wide range of applications, and it is sure to continue to be a popular choice for engineers and designers in the years to come.

Industrial Applications

- CNC Machines

- 3D Printers

- Robotics

- Medical Equipment

Consumer Applications

- Home Automation

- Automotive Industry

- Aerospace Industry

Advantages of Hybrid Stepper Motors

- High Precision and Accuracy

- Energy Efficient

- Low Maintenance

Remark

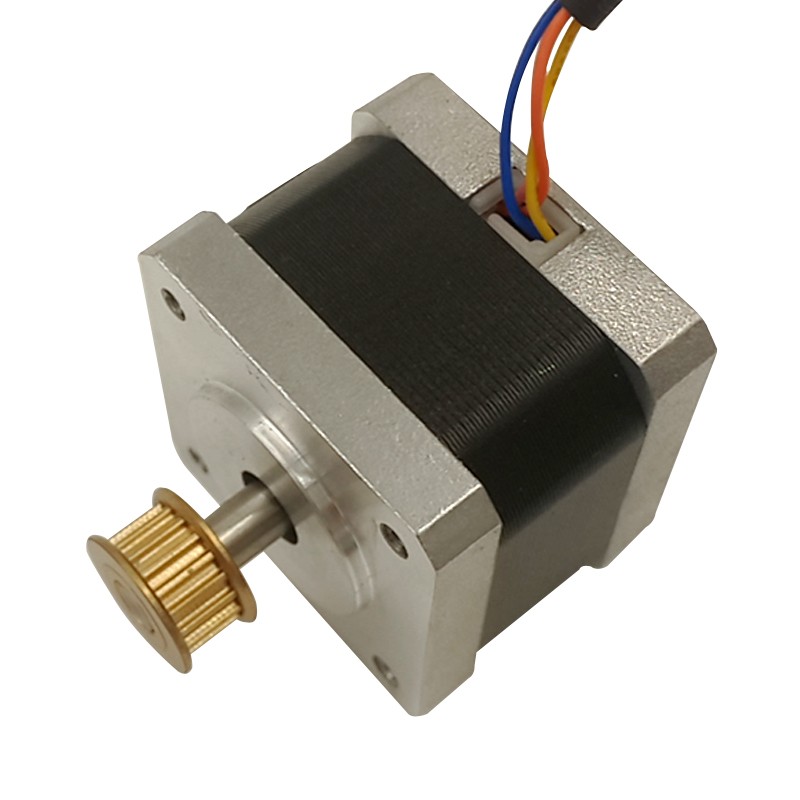

1. Coil resistance, phase number and other electrical performance parameters can be customized according to customer requirements;

2. The installation size, output shaft size, output synchronous pulley or output gear, lead length, and plug specifications can be customized according to customer requirements;

Technique Specification

|

Model NO. |

Rated votage |

Current Phase |

Resistance Phase |

Inductance Phase |

Holding Torque |

Leads |

Rotor Inertia |

Weight |

Length |

||

|

Single Shaft |

Double Shaft |

V |

A |

Ω |

mH |

Oz-in |

g-cm |

|

g-cm2 |

Kg |

mm |

| 39HS20MF-05A |

39HS20MF-05B |

4 |

0.5 |

8.0 |

9.5 |

12.5 |

900 |

4 |

10 |

0.1 |

20 |

| 39HS25MF-05A |

39HS25MF-05B |

5 |

0.5 |

10 |

15.5 |

17 |

1200 |

4 |

11 |

0.12 |

25 |

| 39HS25MF-06A |

39HS25MF-06B |

6 |

0.6 |

10 |

15.5 |

22 |

1600 |

4 |

11 |

0.12 |

25 |

| 39HS34MF-04A |

39HS34MF-04B |

12 |

0.4 |

30 |

43.0 |

25 |

1800 |

4 |

20 |

0.18 |

34 |

| 39HS38MF-05A |

39HS38MF-05B |

12 |

0.5 |

24 |

60.0 |

36 |

2600 |

4 |

28 |

0.2 |

38 |

| 39HS38MF-08A |

39HS38MF-08B |

6 |

0.8 |

7.5 |

7.5 |

24 |

1700 |

6 |

28 |

0.2 |

38 |

| 39HS44MF-03A |

39HS44MF-03B |

12 |

0.3 |

40 |

110.0 |

35 |

2500 |

4 |

36 |

0.25 |

44 |