3D Printing Service

3D Printing Service

With 3D printing, waiting times are drastically reduced, and precision is guaranteed. Complex geometries and detailed designs are no longer challenge. We understand that time is often of the essence, and our 3D printing capabilities are here to ensure you get your parts when you need them with high quality and accurancy. At Foxstar, we offer SLA, SLS and SLM service, choose the most suitable method based on actual needs.

What is SLA 3D Printing

SLA (Stereolithography) 3D printing is an additive manufacturing process that creates three-dimensional objects by selectively curing liquid photopolymer resin layer by layer using an ultraviolet (UV) laser or other light sources.

The advantage of SLA:

1. Diverse Selection of Materials: Offering a wide array of translucent and opaque material options.

2. Exceptional Print Surface Quality: Delivering high-quality printing results with precision and clarity.

3. Versatility Across Industries: Applicable to a broad spectrum of industrial components and parts.

4. Abundant Surface Finish Choices: Providing numerous options for achieving desired surface textures and aesthetics.

What is SLS 3D Printing

SLS (Selective Laser Sintering) 3D printing is an additive manufacturing process that creates three-dimensional objects by selectively fusing together successive layers of powdered material, typically a polymer or metal, using a high-powered laser.

The advantage of SLS:

1. SLS can work with a wide range of materials, including plastics, metals, ceramics, and composites. This versatility allows for the production of parts with different properties, such as strength, flexibility, and heat resistance.Producing functional needs parts.

2. SLS can create intricate and complex geometric shapes that may be difficult or impossible to achieve with traditional manufacturing methods.

3. SLS parts are known for their durability and strength. Depending on the material used, SLS-produced parts can withstand various environmental conditions and mechanical stresses.

4. SLS offers high dimensional accuracy and precision, making it suitable for applications that require tight tolerances and fine details.

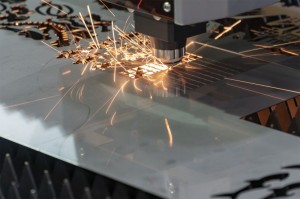

SLM 3D Printing

SLM, or Selective Laser Melting, is an advanced additive manufacturing process that is primarily used for the production of metal parts and components. It is a powder-bed fusion technique that creates complex and fully dense metal objects layer by layer.

The advantage of SLM:

1. SLM allows the fabrication of intricate and highly complex geometries that are difficult or impossible to achieve using traditional manufacturing methods

2. SLM offers exceptional dimensional accuracy and precision. It can achieve tight tolerances and fine details, making it suitable for applications where exact specifications are critical.

3. SLM supports a wide range of metal materials, including stainless steel, aluminum, titanium, nickel-based alloys, and more.

4. Low Volume Production: SLM is suitable for both rapid prototyping and low-volume production runs, offering a cost-effective solution for small-batch manufacturing.