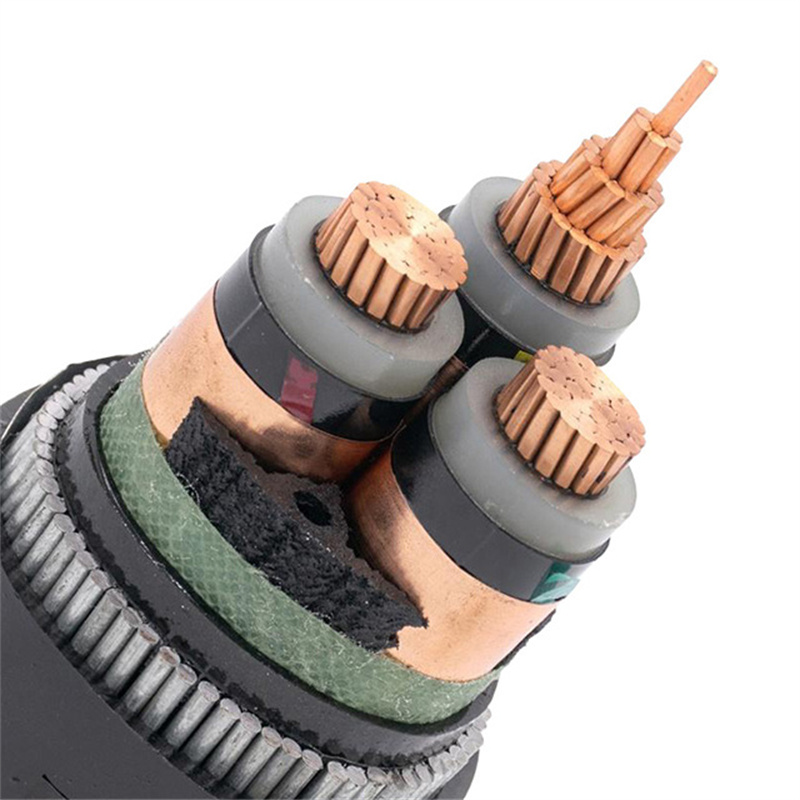

8.7/15kv SWA Steel Wire Medium Voltage Power Cable

Application

XLPE insulated cable functions well for electricity transmission and distribution lines for its excellent electrical and psical properties, including the advantage of simplicity in construction, lightness in weight; convenience in application besides its excellent electrical, thermal, mechanical and anti-chemical corrosion properties.

Constrution

Characteristics

Rated voltage: 8.7 / 15 kV

Conductor: Copper or Aluminum

Minimum installation temperature: 0°C ;

Maximum installation temperature: +60°C;

Installation type: Outdoor – Direct burial;

Minimum operating temperature:-15°C Maximum operating temperature:90°C;

Short-circuit max. conductor temperature: 250°C;

Standards

GB/12706-2008, IEC60502,IEC 60228,IEC60332 BS 5467,BS 6622 , IS 1554 , IS 7098and ICEA S-66-524 etc.

Parameters

|

8.7/15kv 1 Core Medium Voltge Steel Wire Armoured Cable |

||||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Inner Covering Thickness |

Dia. Of Armor Wire |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

1×25 |

4.5 |

1.2 |

1.6 |

1.9 |

28 |

1714 |

0.727 |

30.5 |

140 |

150 |

|

1×35 |

4.5 |

1.2 |

1.6 |

1.9 |

29 |

1874 |

0.524 |

30.5 |

170 |

180 |

|

1×50 |

4.5 |

1.2 |

1.6 |

1.9 |

30 |

2086 |

0.387 |

30.5 |

205 |

215 |

|

1×70 |

4.5 |

1.2 |

2 |

2 |

33 |

2641 |

0.268 |

30.5 |

260 |

265 |

|

1×95 |

4.5 |

1.2 |

2 |

2.1 |

35 |

2990 |

0.193 |

30.5 |

315 |

315 |

|

1×120 |

4.5 |

1.2 |

2 |

2.1 |

36 |

3332 |

0.153 |

30.5 |

360 |

360 |

|

1×150 |

4.5 |

1.2 |

2 |

2.2 |

38 |

3723 |

0.124 |

30.5 |

410 |

405 |

|

1×185 |

4.5 |

1.2 |

2 |

2.2 |

40 |

4174 |

0.0991 |

30.5 |

470 |

455 |

|

1×240 |

4.5 |

1.2 |

2 |

2.3 |

42 |

4874 |

0.0754 |

30.5 |

555 |

530 |

|

1×300 |

4.5 |

1.3 |

2.5 |

2.4 |

45 |

6056 |

0.0601 |

30.5 |

640 |

595 |

|

1×400 |

4.5 |

1.3 |

2.5 |

2.5 |

49 |

7195 |

0.047 |

30.5 |

745 |

680 |

|

1×500 |

4.5 |

1.4 |

2.5 |

2.6 |

54 |

8485 |

0.0366 |

30.5 |

885 |

765 |

|

8.7/15kv 3 Core Medium Voltge Steel Wire Armoured Cable |

||||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Inner Covering Thickness |

Dia. Of Armor Wire |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

| 3×25 |

4.5 |

1.4 |

2.5 |

2.7 |

54 |

5224 |

0.727 |

30.5 |

120 |

125 |

| 3×35 |

4.5 |

1.5 |

2.5 |

2.8 |

57 |

5790 |

0.524 |

30.5 |

140 |

155 |

| 3×50 |

4.5 |

1.5 |

2.5 |

2.9 |

60 |

6485 |

0.387 |

30.5 |

165 |

180 |

| 3×70 |

4.5 |

1.6 |

2.5 |

3 |

64 |

7501 |

0.268 |

30.5 |

210 |

220 |

| 3×95 |

4.5 |

1.6 |

2.5 |

3.1 |

67 |

8548 |

0.193 |

30.5 |

255 |

265 |

| 3×120 |

4.5 |

1.7 |

2.5 |

3.2 |

70 |

9663 |

0.153 |

30.5 |

290 |

300 |

| 3×150 |

4.5 |

1.8 |

3.15 |

3.4 |

75 |

11811 |

0.124 |

30.5 |

330 |

340 |

| 3×185 |

4.5 |

1.8 |

3.15 |

3.5 |

78 |

13282 |

0.0991 |

30.5 |

375 |

380 |

| 3×240 |

4.5 |

1.9 |

3.15 |

3.7 |

84 |

15567 |

0.0754 |

30.5 |

435 |

435 |

| 3×300 |

4.5 |

2 |

3.15 |

3.8 |

88 |

17937 |

0.0601 |

30.5 |

495 |

485 |

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It’s no problem.

Q: Can I get some sample to check your quality?

A: Yes, you can require for samples to check our quality. Sample is free, but the freight charge should be paid.

Q: What’s the terms of payment?

A: 30% T/T deposit, 70% T/T balance payment before shipment.

Q: How can we guarantee quality?

A: Our factory will always send you the pre-production sample before mass production;

Our factory will always have a final Inspection before shipment.

Contact us for more informations about our products, our professional team will serve you and customized according to your requirements.