8 Year Exporter Alloy Wheels Type Turn Table Shot Blasting Machine Manufacturer - Steel pipe shot blasting machine – Binhai Jincheng

We stick with the theory of “quality first, company first, steady improvement and innovation to satisfy the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Shot Blast System , Machinery Shot Blasting Machine , Roller Conveyor Type Shot Blasting Machine , Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

8 Year Exporter Alloy Wheels Type Turn Table Shot Blasting Machine Manufacturer – Steel pipe shot blasting machine – Binhai Jincheng Detail:

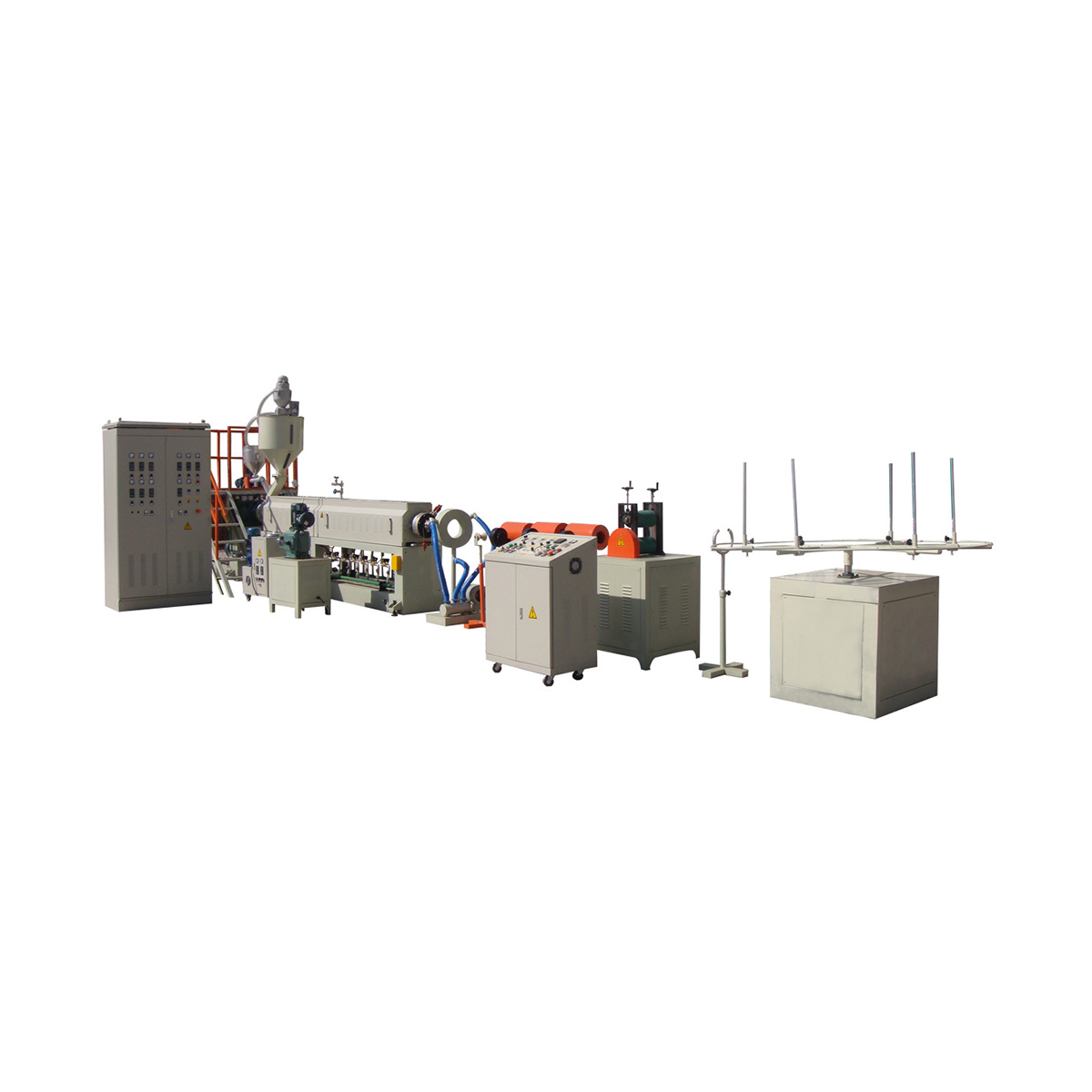

Steel pipe shot blasting machine

Steel pipe shot blasting machine is a new type of special shot blasting equipment designed to user requirements, which is specially used for cleaning the outer wall of large circular steel pipes and wind power wind towers, and at some situations to clean inner and outer walls surfaces of steel pipes. Through shot blasting, not only can remove rust, scale, welding slag, casting sand on the surface of the workpiece, but it also can reduce the internal stress of the workpiece, improve the fatigue resistance of the workpiece, make the surface of the workpiece metallic and increase the surface of the workpiece The adhesion of the paint film during painting enhances the anti-corrosion performance of the steel pipe and round steel and prolongs the service life of the workpiece. And finally achieve the purpose of improving the entire surface and inner quality of the pipes.

|

Tech data |

QGW20-50 |

QGW80-150 |

|

|

Tidy up tube diameter(mm) |

30-500 |

250-1500 |

|

|

Abrasive flow rate(kg/min) |

2X260 |

2X260 |

2X750 |

|

Cleaning speed(m/mim) |

0.5-4 |

0.5-4 |

1-10 |

main features of Steel pipe shot blasting machine

1. The shot blasting device adopts upward shot blasting arrangement. Because the bottom surface of the steel pipe with different diameters is conveyed on the roller table at the same height, the shot blaster shoots from bottom to top, and the distance between the abrasive and the surface of the steel pipe is basically the same, that is, the cleaning effect is more uniform.

2. The workpiece continuously passes through the inlet and outlet of the shot blasting machine. Due to the cleaning of the steel pipe with a large diameter, in order to prevent the abrasive from flying outside, the machine uses a multi-layer replaceable sealing brush to achieve a perfect seal to the abrasive.

3. The use of centrifugal cantilever novel high-efficiency multi-function shot blasting machine, large shot blasting amount, high efficiency, rapid blade replacement, with the overall replacement performance, easy maintenance.

4. Simulated abrasive diagram (including the determination of the model, number and spatial layout of the shot blasting machine) and all drawings of the shot blasting machine are completely drawn by computer-aided design. The utilization rate and labor productivity of the abrasive are improved, the cleaning effect is ensured, and the wear on the chamber body guard plate is reduced

4. A full-curtain BE-type slag separator is used, which greatly improves the separation amount, separation efficiency and shot blasting quality, and reduces the wear on the shot blasting device.

5. Rolling Mn13 steel plate is used for protection in the cleaning room, and the protective plate is fixed by a special nut. It is simple and convenient to replace and has a long service life.

6.Conveying linkage line

The transmission linkage line can realize stepless speed regulation through frequency converter. In order to ensure that when the steel pipes of various specifications are shot at a specified speed, the steel pipe has enough turnover times in the shot blasting chamber to obtain the best shot blasting effect.

The adjustment of the roller spacing is done by the adjusting device. Each roller group is connected by a connecting rod, so that synchronous adjustment can be achieved. The adjustment method can be adjusted according to different pipe diameters according to user requirements.

Each roller can rotate around the center of the bracket to adjust its angle to the conveying direction. When the speed of the roller is constant, the conveying speed and rotation speed of the workpiece are changed. The angle of the roller is adjusted synchronously by the ratchet and pawl mechanism.

The power of each roller is generated by the reducer, and different numbers of reducers can be arranged according to the power requirements. The outer circle of the roller is solid rubber, which has both elasticity and wear resistance and can effectively support the steel pipe.

7、Steel pipe keeps rotation.

8、The dust collector adopts environmental protection pulse filter cartridge blowback dust collector. The dust collector has a large filtering area and good filtering effect.

9、The machine design is novel in design, easy to use and maintain.

10、Using automatic fault detection device to realize automatic shutdown alarm function. This machine has the characteristics of advanced structure, reasonable design, reliable operation and high production efficiency.

11、With no pit structure, easy maintenance.

Steel pipe shot blasting machine Structural characteristics

1.cleaning sequence

Loading (user-supplied) → linkage line → enter shot blasting room → shot blasting (workpiece rotates while advancing) → feed out shot blasting room → linkage line → unloading (user-supplied)

2.Abrasive Circulation Sequence

Abrasive Storage → Flow Control → Shot Blasting Workpiece → Bucket Elevator Vertical Lift → Pellet Separation → (Recycling)

4. Structural characteristics

The structure of the machine consists of feeding roller table (12 meters), shot blasting machine, feeding roller table (12 meters), air control system, electric control system and dust removal system.

The shot blasting machine is composed of shot blasting chamber, shot blaster assembly, shot hopper and grille, shot slag separator, elevator, platform ladder railing, shot supply system and other components.