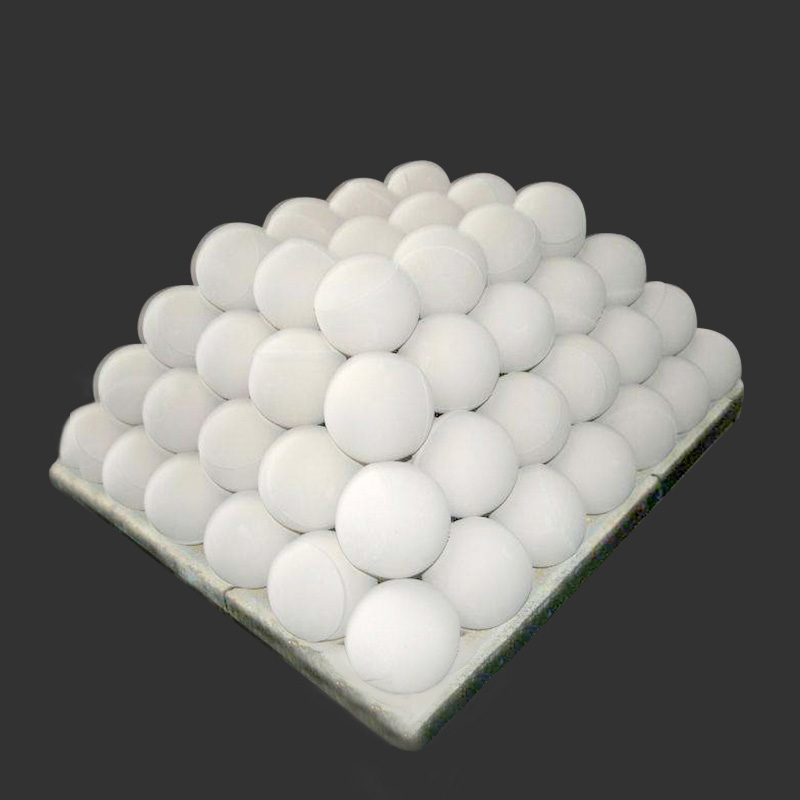

Alumina ball

APPLICATION

The products are widely used in ceramic, paints, color, cement, coating, refractory material, pharmaceutical,chemical, mine industry etc. The advantages are super hardness, high density, low wear loss, regular shape and good corrosion-resistance etc.

1) Formed by ISO-STATIC pressing and Japanese rolling technology, high density and hardness which can promote the grinding efficiency, reduce the grinding time and increase the production capacity through increasing the available space for grinding.

2) Low wear loss which can reduce the grinding cost, prolong the service life, high cost-effective.

3) The main content is alumina which has no pollution to the material (such as ceramic).

4) High whiteness can promote the ceramic body’s whiteness.

STANDARD SIZES OF ALUMINA BALL

| Series

Size Tolerance Size |

MEGA70 | MEGA75 | MEGA85 | MEGA93 | MEGA93S | MEGA95 |

|

Φ30mm–Φ40mm

|

±1.5mm | ±1.5mm | ±1.5mm | ±1.5mm | ±1.5mm | ±1.5mm |

| Φ50mm–Φ60mm | ±2mm | ±2mm | ±2mm | ±2mm | ±2mm | ±2mm |

| Φ70mm–Φ80mm | ±3mm | ±3mm | ±3mm | ±3mm | ±3mm | ±3mm |

PERFORMANCE INDEX (ALUMINA BALL AND LINING BRICK)

| Product

Performance Index |

MEGA70 | MEGA75 | MEGA85 | MEGA93 | MEGA93S | MEGA95 |

| Bulk Density(g/cm3) | 2.95-3.06 | 3.2-3.3 | 3.30-3.40 | 3.60-3.70 | 3.65-3.75 | 3.65-3.75 |

| Rate of Water Absorption(%) | ≤0.02 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Wear loss (%) | 0.018 | 0.01-0.015 | 0.006 | 0.008 | 0.005 | 0.005 |

| Color | Yellowish | Milky White | White | White | White | White |