Alumina Ceramic Ring

Advantages of alumina ceramic ring

1.With excellent insulation, high frequency loss is relatively small but high frequency insulation is good.

2.With the characteristics of heat resistance, low thermal expansion coefficient, high mechanical strength and good thermal conductivity.

3.With the characteristics of chemical corrosion resistance and melting gold properties.

4.With non-combustible, rust-proof, Hardness, not easy to damage the excellent properties.

5. With high wear resistance and excellent sliding properties.

Application of alumina ceramic ring

Electronics industry: Because of its excellent heat and mechanical impact properties, as well as corrosion resistance, the highest performance of electrical systems will use ceramic seals.

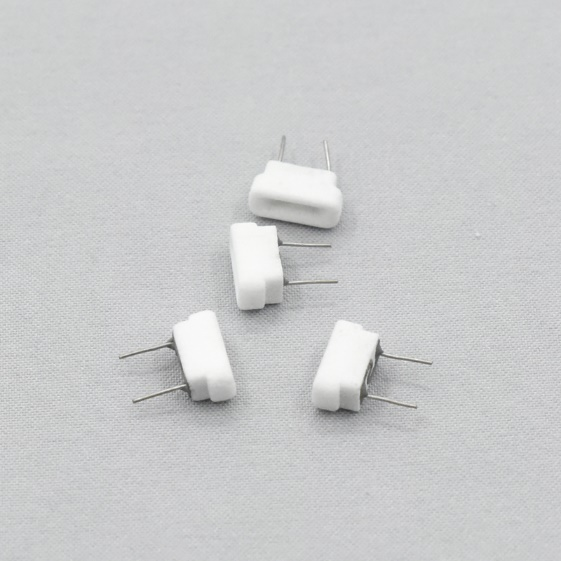

Healthcare industry: Because some medical devices require special seals that are resistant to corrosion and biocompatible, ceramic seals are used. Ceramic seals play an important role in implantable electronic devices. Researchers have created a variety of implantable electronic devices, including defibrillators and nerve stimulators. The lead of the implanted device must be sealed, with a sealed ceramic seal ring around each pin.

Aerospace industry: Alumina ceramic components are ideal for aerospace applications because they can withstand high temperatures, vibration and mechanical shocks in aircraft engines. Ceramic seals are commonly used to seal gas turbine engine thermocouples, fuel line assemblies and fire detection system terminals.

New energy vehicle industry: Ceramic seal ring has excellent wear resistance, dimensional stability ,while reducing noise emission level, prolong the service life of all types of pumps in the vehicle.