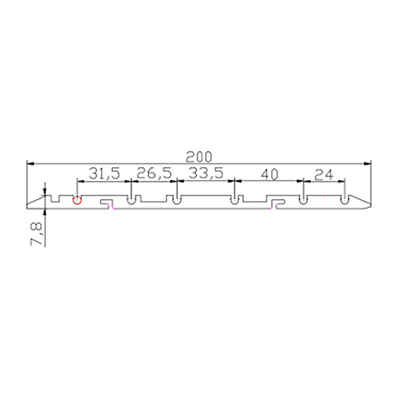

Aluminum extrusion profile custom No GKX-JN003

Product Details

SPECIFICATIONS

6063-T5 Or As Demand

3.535kg/m

CHARACTERISTICS

Welding = Excellent

Machining / Grinding = Excellent

Bending / Forming = Excellent

Wear Resistance =Excellent

Corrosion Resistance =Excellent

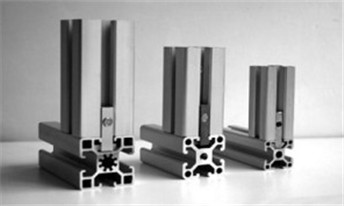

Cross-section or Actual Sample

The higher the dimensional tolerance requirements of the profile, the more difficult it is, the more cavities in the profile, , then the die’s foreman is easy to be punched off during extrusion. The wall thickness of the profile will be different for different sizes of extruders and profile configurations

Aluminum alloy grades

Internationally registered aluminum alloy grades

There are more than 1,000, from 1,000 to 8,000

Each grade has several Each grade has multiple states, in terms of hardness, strength, corrosion resistance, processability, weldability, decorative properties of difference

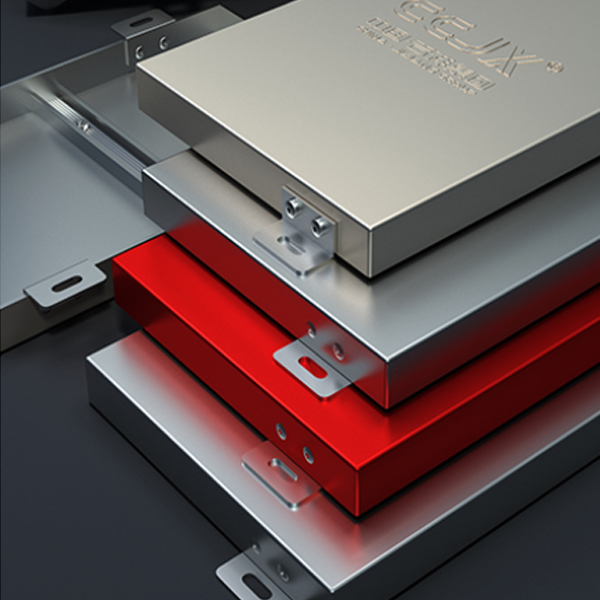

Surface Treatment

Commonly used aluminum profile surface treatment has “spray coating, sandblasting, electrophoresis, oxidation, pulling silk, imitation wood grain, chemical polishing, PTFE,etc

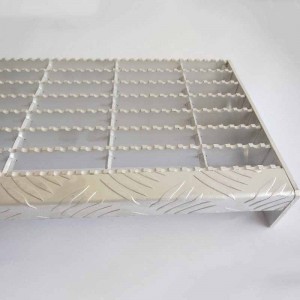

Finishing Requirements

Aluminum extrusion molding in addition to surface treatment we can also profile some post-processing, such as cutting, punching, bending bending, etc.

Customized Process of Mold Opening

Customized Process of Mold Opening

Open mold customization requirements:

1、Dimension drawings Dimension drawings (CAD or 3-dimensional format, simple structure can not need drawings)

2. Psical samples

Quality Control

1. Certified quality management systems

7.Measuring tools and test equipment

2. Incoming inspection of raw materials and outsourced products, with first piece inspection records

3.Have process inspection, 2 hours a time

4.Shipment inspection

5. Perform incoming material, first sample, process and shipment inspections in accordance with inspection work instructions

6. Have a pass rate and defective rate of the quality of the monthly report

7. Measuring tools and test equipment

8. Production process work instructions

9. Design and production of molds and jigs and fixtures.