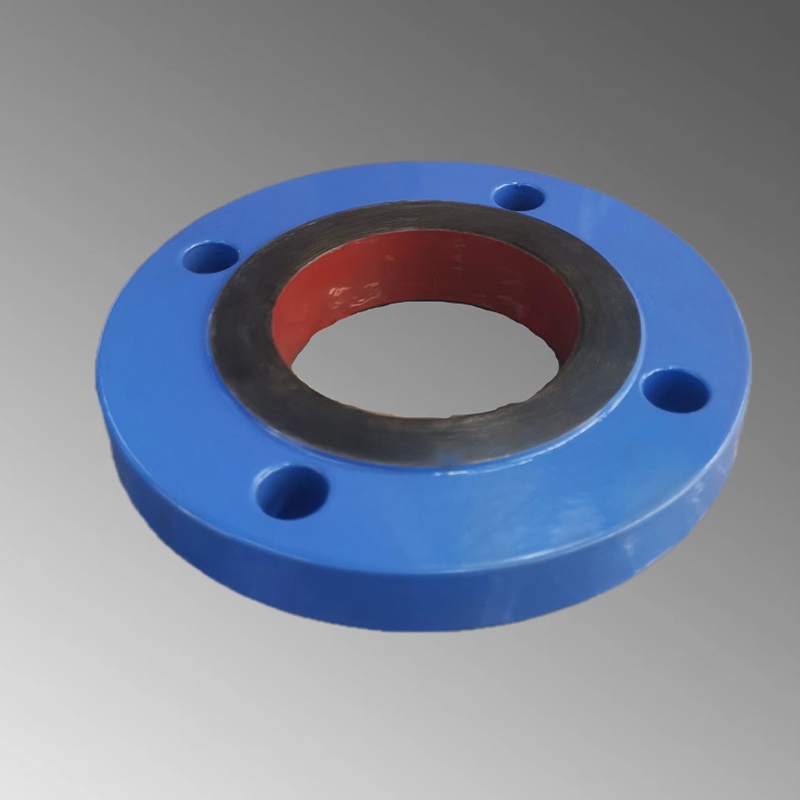

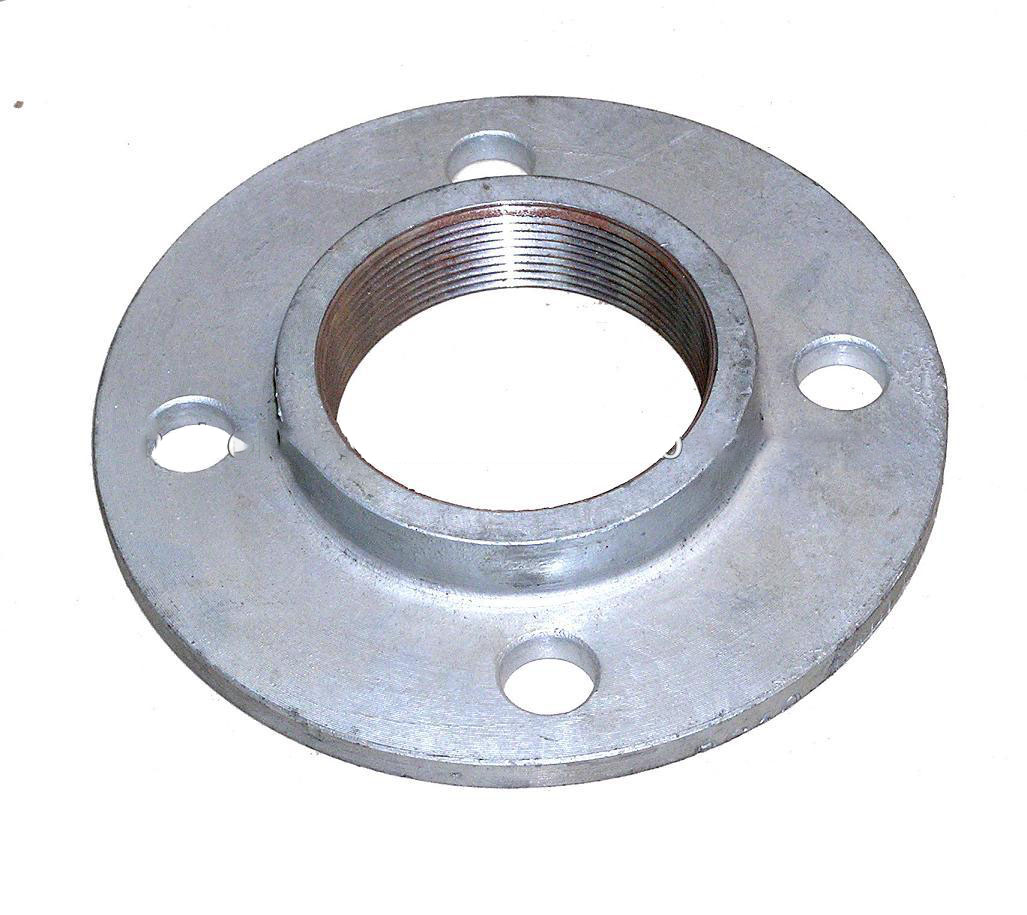

Anticorrosion Flange

details

|

Manufacturing Standards: |

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, GB/T12459, GB/T13401, SH3408, SH3409, JIS B2311/2220, DIN2617/2616/2615 |

|

Size: |

1/2〞(DN15)to 60〞(DN1500) |

|

Pressure: |

150LBS,300LBS,400LBS,600LBS,900LBS,1500LBS,2500LBS. DIN Standard PN-2.5,6,10,16,25,40,50,64,110,150,250,320,400. |

|

OD: |

3/8”—40” |

|

Material: |

CS A105/SA105N,SS 304/3034L,316/316L |

|

Surface: |

RF,MFM,TG,RJ,RF |

|

Carbon Steel |

ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70 |

|

Surface Treatment: |

Antirust Paint,Oil Black Paint,Yellow Transparent,Zinc Plated,Cold and Hot Dip Galvanized |

|

Material Grades |

|

|

Carbon Steel |

ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8 |

|

Stainless Steel |

ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L |

|

Duplex & Super Duplex Steel |

ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61, 2205 (UNS No. S31803), 2507 (UNS No.S32750),1.4462,1.4410,1.4547 |

|

Alloy Steel |

ASTM A182 F1, F5, F9, F11, F22, F91 |

|

Copper Alloy Steel |

UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C70600 (Cu -Ni- 90/10), C71500 (Cu -Ni- 70/30) |

|

Nickel Alloy |

Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500)Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625) Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II). |

USE &APPLICATION

- Commonly used in the following industries:

- architecture

- bridge

- Petrochemical industry

- shipbuilding

- project

- Offshore and onshore services

- Power generation industry

- Food processing industry

- oil and gas industry

- sugar industry

Products are packaged to ensure that there is no damage during transit.

In case of exports, standard export packaging is done in wooden cases.

All pipes are marked with Grade, Lot No, Size, Degree and our trade mark.

On special requests we can also, make custom marking on our products.

Wooden Boxes

Wooden Pallets

Shrink-Wrapped

Carton Boxes

Wooden Boxes

Testing

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiograp Test Report, Third Party Inspection Report

Positive Material Identification – PMI Testing

Chemical Analysis – Spectro Analysis

Mechanical Testing Such as Tensile, Elongation, Reduction of Area

Micro Test

Macro Test

Hardness Test

Pitting Resistance Test

Intergranular Corrosion (IGC) Test

Flaring Test

Flattening Test

Hydrostatic Test

Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

Radiograp Test

Dye Penetrant Test (DP Test)

Product Description

Flange is to make the pipe and pipe and valve interconnection parts, connected to the end of the pipe; also used in the equipment import and export of the flange, for the connection between the two equipment is to make the pipe and pipe interconnection parts, connected to the end of the pipe. It is a kind of accessory products of pipeline. The main materials of forged flange are carbon steel, alloy steel, stainless steel. The main standards are national standard, electric standard, American standard, German standard, Japanese standard and so on. The main anti-corrosion treatment is oiled and galvanized. Forged flanges have better pressure and temperature resistance, and are generally used in high pressure and high temperature working environment. Casting out of the flange, the blank shape and size is accurate, processing small, low cost, but there are casting defects (porosity. Cracks. Inclusions); casting internal organization streamline set her poorer (if cutting parts, streamline worse);.

Forging flange is generally lower than the casting flange carbon content is not easy to rust, forging good streamline, the organization is more dense, mechanical properties are better than casting flange.

Improper forging process will also appear grain size or uneven, hardening crack phenomenon, forging cost is higher than casting flange.

Forgings can withstand higher shear force and tensile force than castings.

The advantage of casting is that you can get to explore the honey out of the more complex shape, the cost is relatively low.

The advantage of forging is that the internal organization is uniform, there is no casting of porosity, inclusions and other harmful defects.

From the production process to distinguish between casting flange and forging flange, such as centrifugal flange belongs to a casting flange.

The forging process generally consists of the following procedures, i.e., selecting high-quality billets for discharging, heating, forming, and cooling after forging. Forging process methods are free forging, die forging and tire film forging. Production, according to the size of the quality of the forgings, the production of the number of batches of Xiqiqi buried to choose a different forging method.

Basic process: free forging, the shape of the forging is through a leg war enterprise worship some of the basic deformation process will be billet gradually forged.

The basic processes of free forging are upsetting, drawing, punching, bending and cutting.

1. Upsetting Upsetting is the operation process of forging the original billet along the axial direction so as to reduce its height and increase its cross-section. This process is commonly used in forging gear blanks and other disk-shaped forgings. Upsetting is divided into all upsetting and local forging two kinds.

2. Drawing length Drawing length is the forging process to increase the length of the blank and reduce the cross-section, usually used to produce shaft blanks, such as lathe spindles, connecting rods and so on.

3. Punching The forging process of punching out through-hole or non-through-hole with a punch on the billet.

4. Bending the billet into a certain angle or shape of the forging process.

5. Twisting A forging process in which one part of a billet is rotated at an angle relative to another part.

6. Cutting The forging process of dividing the billet or removing the head.

Die forging is known as model forging, the heated billet placed in the forging die fixed in the die forging equipment forging.

1.the basic process of die forging die forging process: material, heating, pre-forging, final forging, punching even skin, cutting edge, tempering, shot blasting. Commonly used processes are upsetting, elongation, bending, punching, molding.

2. Commonly used die forging equipment Commonly used die forging equipment are die forging hammer, hot die forging press, flat forging machine and friction press.

Commonly speaking, the quality of forged flange is better, generally produced by die forging, crystal organization is fine, high strength, of course, the price is also more expensive.

Whether casting flange or forging flange belongs to the flange commonly used manufacturing methods, depending on the strength requirements of the parts to be used, if the requirements are not high, you can also choose the turning system flange.