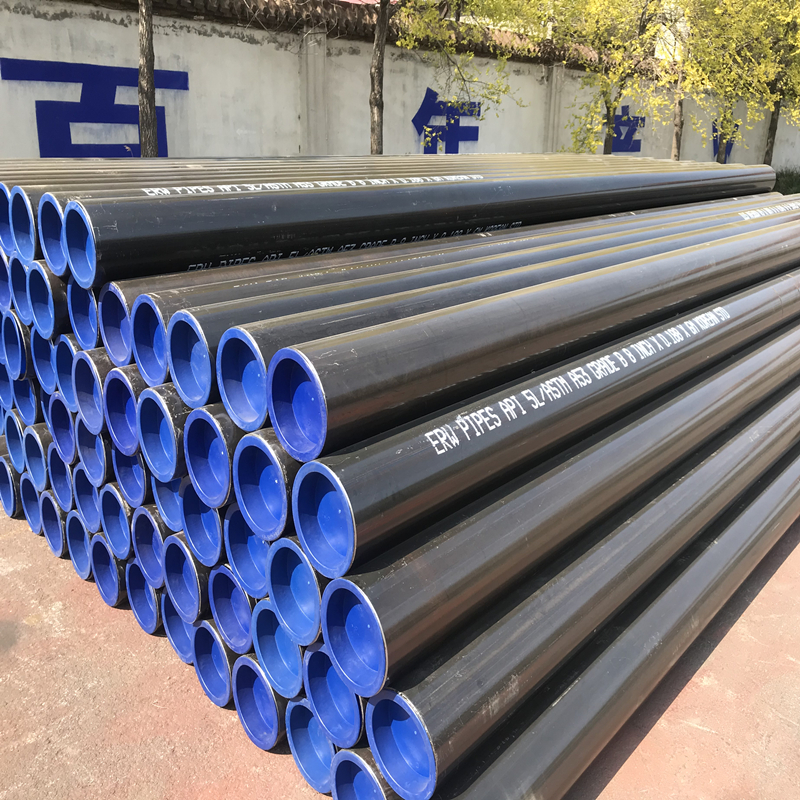

API 5L ASTM A53 ERW Varnish Coating Black Steel Pipe

Product Information

ERW steel pipes are manufactured by low-frequency or high-frequency resistance “resistance”. They are round pipes welded from steel plates with longitudinal welds. It is used to transport oil, natural gas and other vapor-liquid objects, and can meet various requirements of high and low pressure. At present, it occupies a pivotal position in the field of transportation pipes in the world.

During ERW pipe welding, heat is generated when current flows through the contact surface of the welding area. It heats the two edges of the steel to the point where one edge can form a bond. At the same time, under the action of the combined pressure, the edges of the tube blank melt and squeeze together.

Usually ERW pipe maximum OD is 24” (609mm), for larger dimensions pipe will be manufactured in SAW.

What kind of pipes (standards) could be made in ERW processes

There are a lot of pipes could be manufactured by ERW process. Here below we list for the most common standards in pipelines.

Carbon steel pipe in ERW

ASTM A53 Grade A and B API ERW Line pipe

API 5L B to X70 PSL1 (PSL2 shall be in HFW process) And etc.

Advantages of ERW pipe

High efficiency, low cost, material saving, easy automation.

| Standard | ASTM A53 ,API 5L |

| Material | gr.a,gr.b,195-q345,x42,x46,x65,x70 |

| OD | 19.05-660MM |

| W.T | 1.0-20MM |

| Length | 3M/4M/5.8M/6M/6.4M /12M |

| Packing | In bundles, with hexagonal water proof plastic tarpaulin cover. steel tags |

| Payment | at sight L/C or 30%T/T |

| Certificate | ISO9001,API |