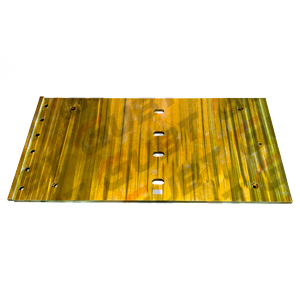

API 7K Premium Casing Slip equivalent to NOV

Application

Casing slips are mainly used in oil, natural gas and other drilling projects for holding and suspension casing. During the drilling process, the casing needs to be fixed to the well wall to prevent collapse and protect the well wall. Casing slips can effectively fix casing and ensure its stability and safety.

casing slip has the following futures and technical specification:

Features

· Forged material for better strength

· Interchangeable with other brands

· Suit for standard API insert bowls

· Large handling range, light weight and large contact area on the taper.

Write your message here and send it to us