ASEAN Fodi (Wuming) NMP equipment recycling system

| Project: ASEAN Fodi (Wuming) NMP equipment recycling system (Production order No. : PJ23021709.PJ23052708) | ||||||||||||

| Customer demand parameter | Equipment parameter | |||||||||||

| Air volume: | 220000m³/h | Equipment type | Treated air volume | Equipment size | Interior material | Tower material | Tail gas emission concentration | |||||

| Production line (positive and negative) : | 2 double layer coater | diameter | Altitude | |||||||||

| NMP liquid concentration: | ≥90% | PJNMP22W | 220000m³/h | φ1600 | 12800 | Aluminium sheet | Stainless steel | 20mg/m³ | ||||

| Heat transfer efficiency: | ≥85% | |||||||||||

| NMP gas exhaust index: | ≤20mg/m³ | |||||||||||

| Floor area: | 360㎡ | |||||||||||

| Project features: Heat recovery + condensation freezing + water absorption tower. | ||||||||||||

| Project features: large air volume automatic NMP recovery processing, heat recovery, condensation freezing, water tower absorption, F8 filtration, auxiliary pipeline system, improve the return air temperature, high efficiency and energy saving, and effectively balance the return air humidity, return air concentration, return air impurities and high concentration NMP liquid recovery. | ||||||||||||

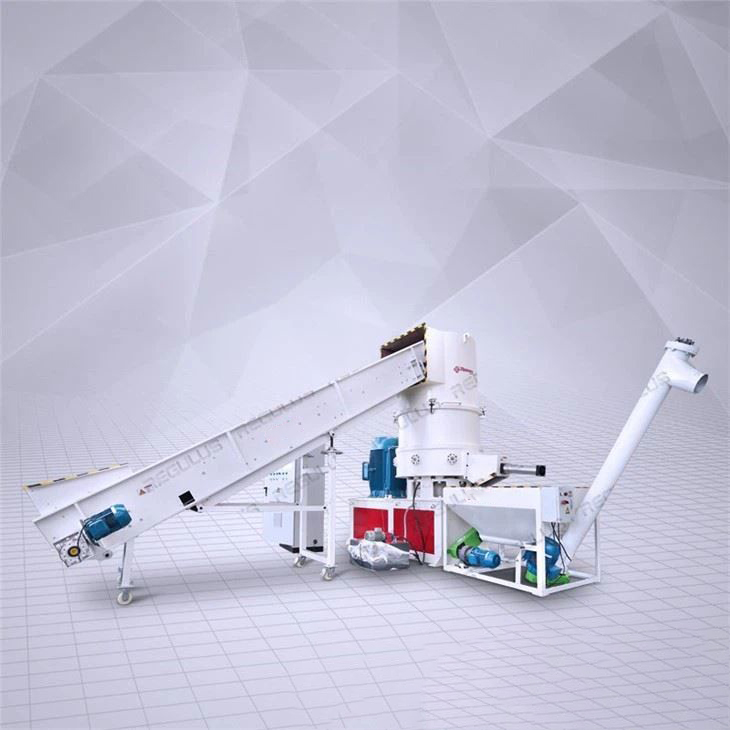

Condensation Unit

The condensation unit is designed to condense the gaseous NMP present in the exhaust gases emitted during the coating production process and recover it in liquid form.

The principle is based on the fact that the saturation concentration of gaseous NMP in the air varies at different temperatures. By passing the hot air containing a high concentration of NMP through the condensation unit, where it undergoes heat exchange with chilled water, the temperature is lowered to the desired value. At this target low temperature, the gaseous NMP that exceeds the saturation concentration condenses and precipitates into a liquid state. It is then collected through functional components such as demisters within the condensation unit, achieving the purpose of recovering and treating the gaseous NMP.