Aseptic Bag in Drum Filling System for Fruit Juice Paste Puree

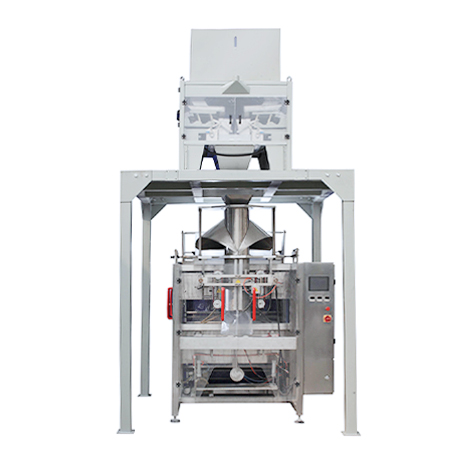

Aseptic bag in drum filling system is one system designed for filling material which is semi-finished products. Filled products are mainly exported or sold to food factory for further processing. Widely used in the filling of the following products, such as tomato paste, concentrated juice, purees, pulp, dairy products, etc.

Aseptic liquid filling machine normally work with UHT sterilizer to form aseptic bag filling line. After processing by aseptic bag filling system, natural fruit juice or pulp can be stored at a normal temperature for over a year, concentrated fruit juice or paste can be stored for over two years.

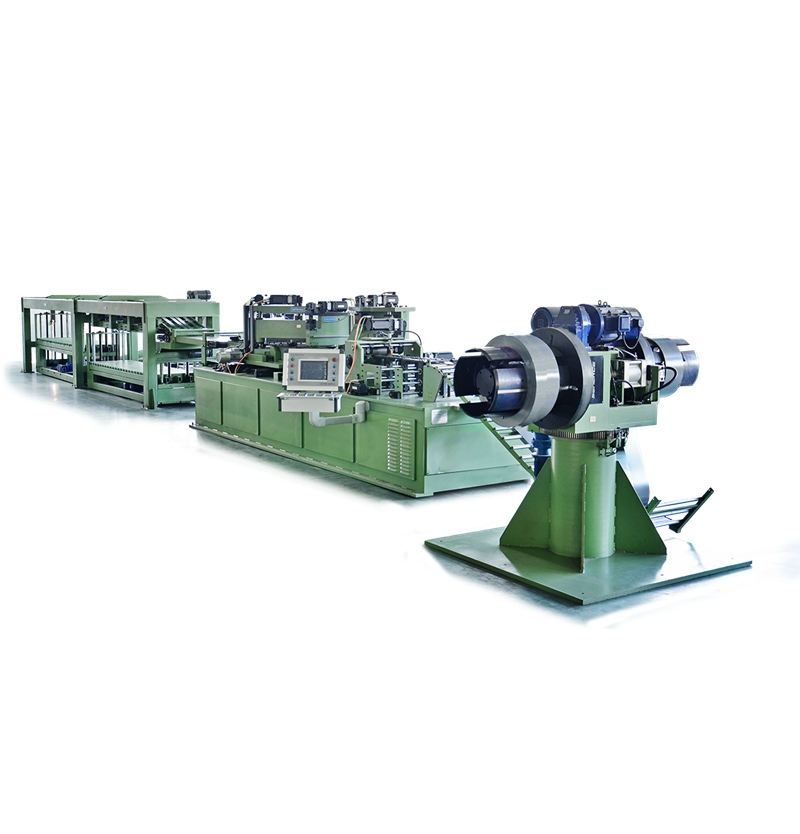

Aseptic bag filling machine mainly consist of aseptic filling head, filling accuracy control device, aseptic valve, pneumatic tray(for 1~25L bags), independent control system, roller conveyor, belt conveyor(for small bags), frame. Main working steps of Aseptic bag filling machine are: choosing bag type on touch screen, put bag on filling head, steam injection, complete aseptic bag mouth’s sterilization, opening, filling and sealing in a commercial sterile environment, output filled bag.

1. Main structure adopts SUS304 stainless steel.

2. Combined Italian technology and conform to Euro-standard.

3. Applicable bag spout size: 1 inch or 2 inch.

4. Applicable bag volume: 200L, 220L(1~25L, 1000L, 1400L are also available.)

5. Independent Germany Siemens Control System

6. Steam barrier protection is available.(valves, filler head, moving parts)

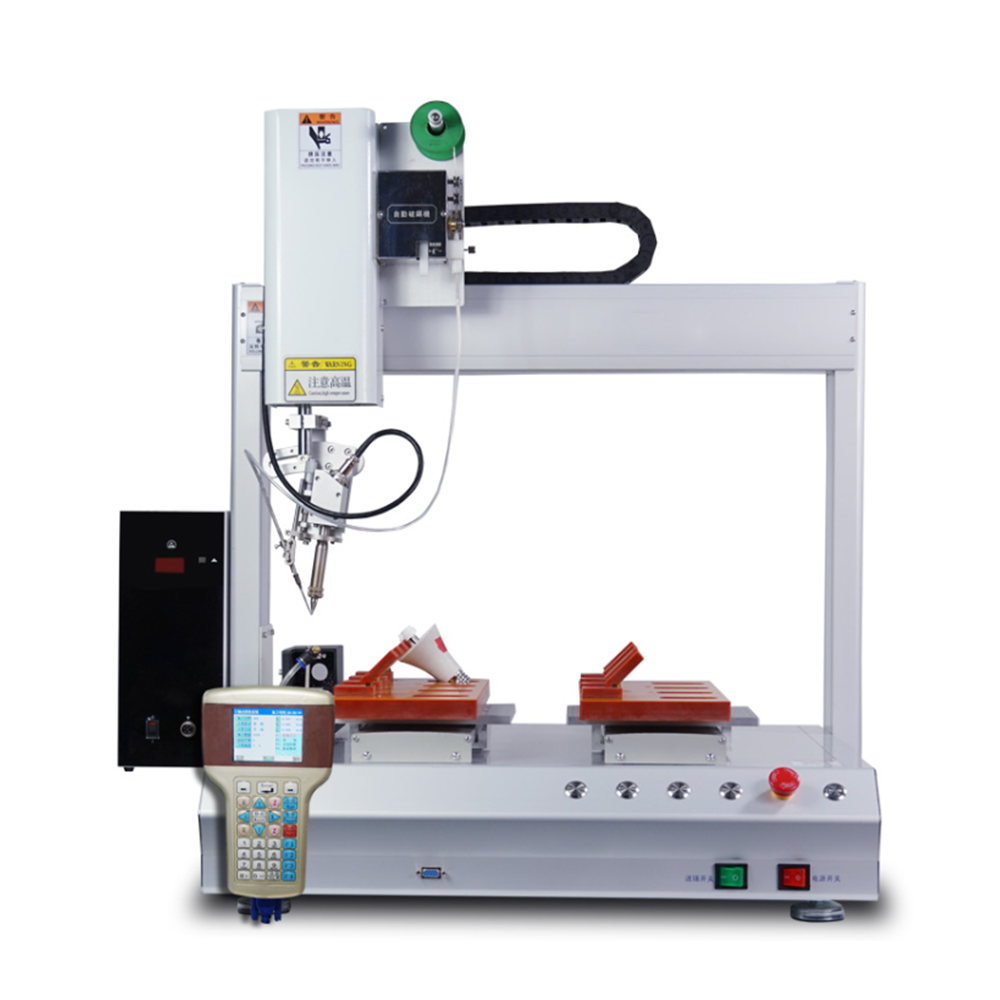

7. Flowmeter or weighing system for choice to controlling filling accuracy.

8. SIP & CIP is available( online running with sterilizer).

9. Easy to operate and low cost in maintenance.

10.Key links adopts international and reliable brand to guarantee the stability of aseptic bag filling machine

1. Juice/ Concentrated juice

2. Puree/Concentrated Puree

3. Fruit and vegetable Paste/Jam

4. Coconut water/concentrate coconut water

5. Coconut milk/ Coconut cream

6. High/Low acid liquid product

7. Syrup

8. Soup

|

Name |

Single head Aseptic Bag in Drum Filling System |

Double head Aseptic Bag in Drum Filling System |

Bag in box Single head Aseptic Filler |

Bag in box Double head Aseptic Filler |

BIB & BID Single head Aseptic bag Filling Machine |

BIB & BID Double head aseptic bag Filling Machine |

BID & BIC Single head Aseptic liquid Filling Machine |

BID & BIC Double head Aseptic liquid Filling Machine |

|

Model |

AF1S |

AF1D |

AF2S |

AF2D |

AF3S |

AF3D |

AF4S |

AF4D |

|

Bag Type |

BID |

BIB |

BIB & BID |

BID & BIC |

||||

|

Capacity |

up to 6 |

up to 12 |

up to 3 |

up to 5 |

up to 12 |

up to 12 |

up to 12 |

up to 12 |

|

Power |

1 |

2 |

1 |

2 |

4.5 |

9 |

4.5 |

9 |

|

Steam Consumption |

0.6-0.8 Mpa≈50(Single head)/≈100(Double head) |

|||||||

|

Air Consumption |

0.6-0.8 Mpa≈0.04(Single head)/≈0.06(Double head) |

|||||||

|

Bag Size |

200, 220 |

1 to 25 |

1 to 220 |

200, 220, 1000, 1400 |

||||

|

Bag Mouth Size |

1″ & 2″ |

|||||||

|

Metering Method |

Weighing System or Flow Meter |

Flow Meter |

Weighing System or Flow Meter |

|||||

|

Dimension |

1700*2000*2800 |

3300*2200*2800 |

1700*1200*2800 |

1700*1700*2800 |

1700*2000*2800 |

3300*2200*2800 |

2500*2700*3500 |

4400*2700*3500 |

1. Food grade material is adopted for the part contact with food product, meeting food production.

2. Provide cost-effective production lines and equipment with the most reasonable design.

3. Provide professional technical design, equipment drawing, etc.

4. Provide related technology consulting and sale service for free.

5. Provide installation, commissioning and training service.

6. Provide 12 months warrantee and lifelong after sale service.

Tech. is one manufacturer of fruit and vegetable processing line equipment and can customize turnkey solution from A to Z according to clients’ specific requirements. Aseptic Bag in drum Filling System is the most popular machines among our core products. It has obtained series of patents and its safety and stability are widely praised by customers.

Till now, successively obtained ISO9001 quality certification, European CE certification, State-certified High-tech Enterprises honor. Due to long term cooperation with international famous brand such as Germany STEPHAN, Netherlands OMVE, German RONO. and ltaly GEA, a variety of equipment with independent intellectual property rights(40+) has been developed. The company’s products have been recognized by well-known large companies such as Yili Group, Ting Hsin Group, Uni-President Enterprise, New Hope Group, Pepsi, Myday Dairy, etc. With the continuous progress of , we can currently provide one-stop brand services, includes Project Consultation, Process Development, Solution Design, Construction, After Service, etc. Provide targeted services according to the different situations of different customers, and are committed to creating satisfactory projects for customers.