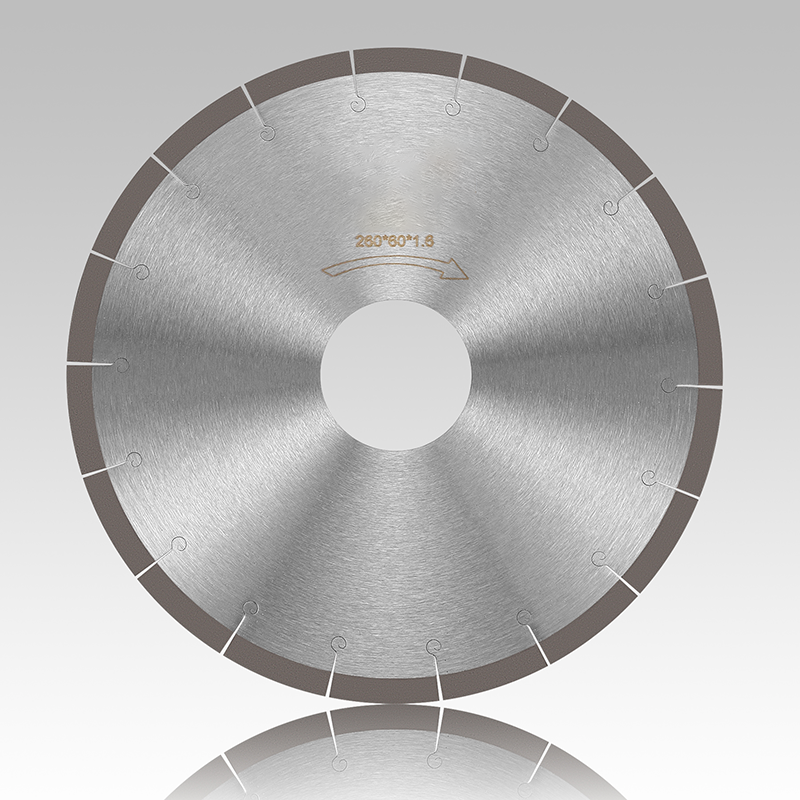

best quality 14 inch CERAMIC TILE welding segment diamond cutting blades diamond saw blade -Cutting disc for Dekton

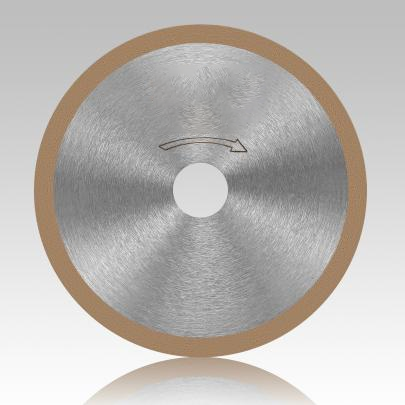

What are the advantages of brazed diamond saw blades?

The cutting efficiency of the brazed diamond saw blade is very high; the diamond is chemically combined with the matrix, and it is not easy to fall off during work; the sharpness is high, the cutting edge is straight, the cutting speed is fast, and the hand feel is simple;

The chip space is large, and the surface abrasive particles are blocked and it is not easy to lose the grinding ability.

①: Good Material: We Use The Best Material From All Of The World.

②:High-Quality:Optimized Formulation To Meet Different processing Requirements

③: Safety Performance: High Bending Strength Of Blade Make The Processing To Be Very Safe.

④:Service Tenet:Your Satisfaction Is Our Pursuit

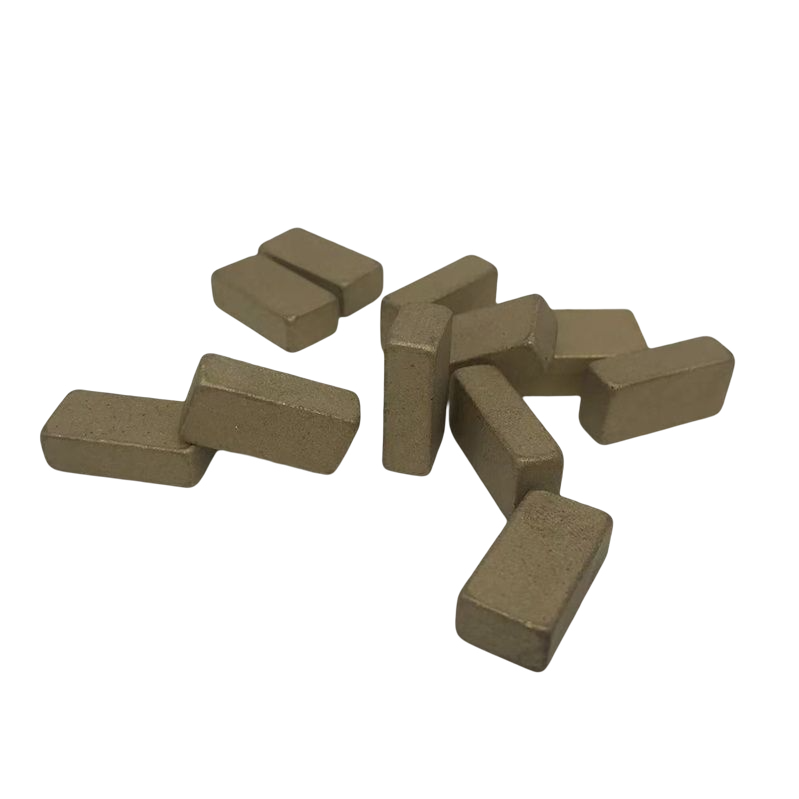

Features of Brazed Diamond Saw Blades

The diamond edge can be 2/3 of the diamond height, so the grinding efficiency is high, and it is beneficial to scour the grinding debris, and the surface abrasive particles are not easy to lose the grinding ability due to clogging; due to the high diamond edge

Large chip holding space, high bonding strength between diamond and matrix, diamond is not easy to fall off: Brazing diamond saw blade is suitable for dry ceramic cutting, microcrystalline stone, artificial stone, marble, etc.

|

TYPE |

DIMENSIONS |

|

Segment diamond saw blades |

Φ190 |

|

Φ210 |

|

|

Φ260 |

|

|

Φ305/310 |

|

|

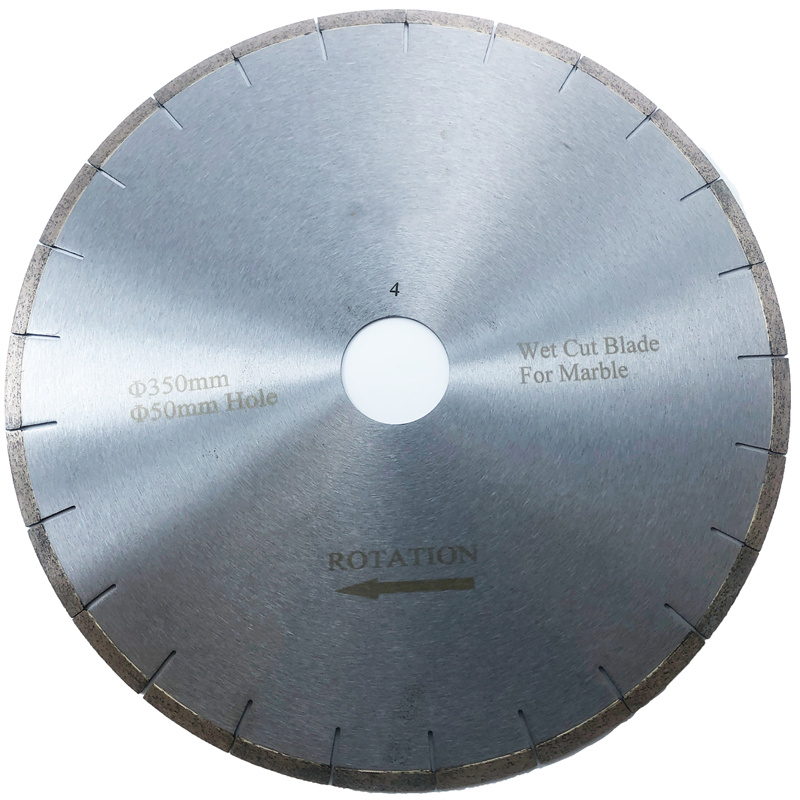

Φ350 |

|

TYPE |

DIMENSIONS |

|

Segment diamond saw blades |

Φ190 |

|

Φ210 |

|

|

Φ260 |

|

|

Φ305/310 |

|

|

Φ350 |

Note: Special specifications can be customized