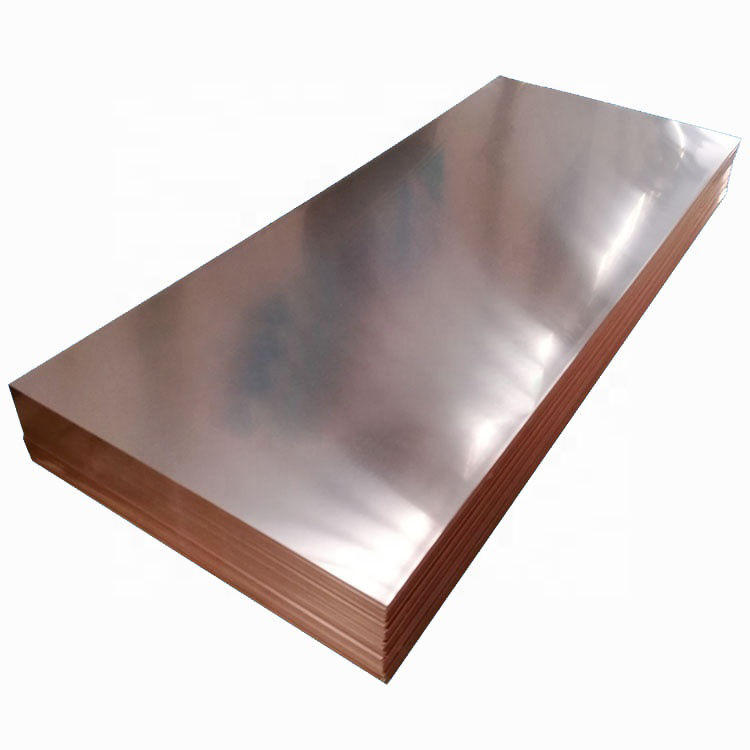

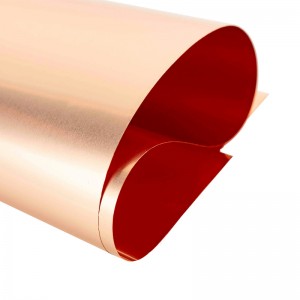

Bronze Plates – Rich Stock, Fast Delivery

Phosphor Bronze

Phosphor bronze, or tin bronze, is a bronze alloy that contains a mixture of copper with 0.5-11% tin and 0.01-0.35% phosphorous.

Phosphor bronze alloys are primarily used for electrical products because they have superb spring qualities, high fatigue resistance, excellent formability, and high corrosion resistance. The addition of tin increases the corrosion resistance and strength of the alloy. The phosphor increases the wear resistance and stiffness of the alloy.Other uses include corrosion resistant bellows, diaphragms, spring washers, bushings, bearings, shafts, gears, thrust washers, and valve parts.

Tin Bronze

Tin bronze is strong and hard and has very high ductility. This combination of properties gives them a high load-carrying capacity, good wear resistance, and the ability to withstand pounding.

Tin’s principal function is to strengthen these bronze alloys. Tin bronze is strong and hard and has very high ductility. This combination of properties gives them a high load-carrying capacity, good wear resistance, and the ability to withstand pounding. The alloys are noted for their corrosion resistance in seawater and brines. Common industrial applications include fittings used to 550 F, gears, bushings, bearings, pump impellers, and many more.

Aluminum Bronze

Aluminum bronze alloys are used for their combination of high strength and excellent corrosion and wear resistance. C95400 aluminum bronze is a popular cast aluminum bronze with high-strength properties and excellent resistance to wear and corrosion. Although this alloy is supplied in the cast condition, it can be heat-treated to enhance its mechanical properties for more demanding applications.

Aluminum bronze alloys are used in marine hardware, shafts, and pump and valve components for handling seawater, sour mine waters, non-oxidizing acids, and industrial process fluids. They are also used in applications such as heavy duty sleeve bearings and machine tool ways. Aluminum bronze castings have exceptional corrosion resistance, high strength, toughness, and wear resistance. Not to mention their good casting and welding characteristics.