BSC Cemented Carbide Rotary Burr Blanks Ball Nosed Cylinder Type

BSC Cemented Carbide Rotary Burr Blanks Ball Nosed Cylinder Type

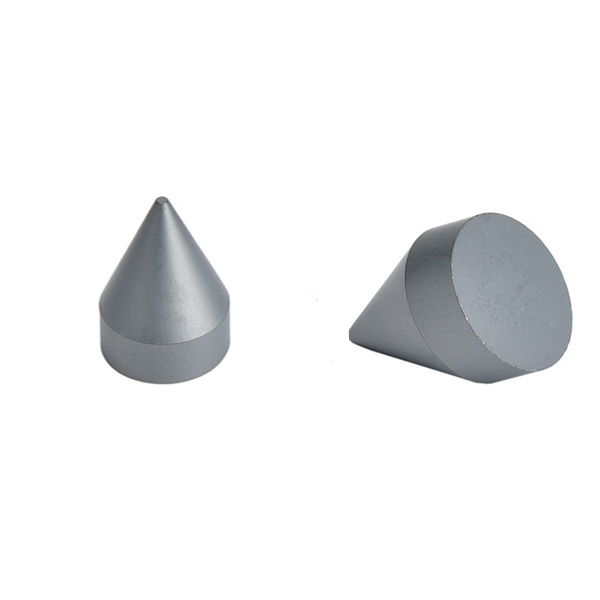

Cemented Carbide Rotary Blanks Ball Nosed Cylinder Type is also called BSC Type.

Tungsten Carbide Rotary Burr Blanks have various types, such as Cylinder, Ball Nosed Cylinder, Ball Nose Tree and so on. These are specially used for manufacturing Rotary Burrs, which are perfectly suitable for deburring, shaping, smoothing welds, enlarging holes, carving and finishing.

Tungsten Rotary Burrs are a new product increasing productivity of several ten times than using hand tools and three to five times than using small emery wheels. And gradually replaced small emery wheels, they are widely known throughout the world for their high efficiency and long lifetime.

Know more about Rotary Burrs please click it

Features of Cemented Carbide Rotary Burr Blanks

High efficiency, and high precisionClean, smooth finishing and good cutting qualityExcellent lifetime and wear resistanceVarious types of rotary burr blanks to process various kinds of metalOEM/ODM, Customization is availableManufacturer supply, factory direct supply, nice priceISO 9001 Certification

Recommend Grade of Cemented Carbide Rotary Burr Blanks

|

MY Grade |

MK10 |

MK15 |

MK20 |

|

|

Grace |

YG6 |

YG7 |

YG8 |

|

|

ISO Grace |

K10 |

K10-K20 |

K20 |

|

|

Co |

% |

6 |

7 |

8 |

|

Grain Size |

μm |

1.2 |

1.2 |

1.2 |

|

Density |

G/m³ |

14.8 |

14.75 |

14.7 |

|

Hardness |

HRA |

91.5 |

91 |

90.5 |

|

HV30 |

1530 |

1470 |

1410 |

|

|

T.R.S. |

Mpa |

2700 |

2800 |

2800 |

Other grades please click here and we can also offered by customs’ requirements.

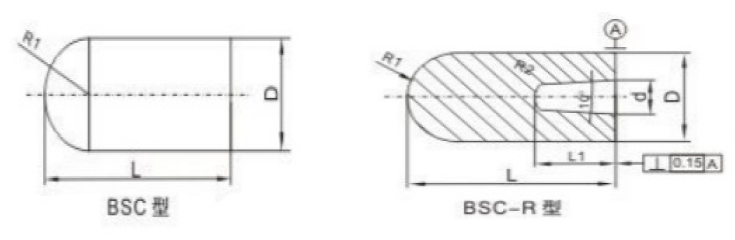

Dimension of Cemented Carbide Rotary Burr Blanks Ball Nosed Cylinder (BSC)Type

Solid Carbide Burr Blanks with hole and customized are available.

All in mm

|

Model |

D |

+0.40 +0.18 |

L |

+0.40 +0.15 |

d |

+0.3 -0 |

L1 |

+0.4 -0.1 |

R1 |

+0.15+0.1 |

|

BSC(R)0613 |

Φ6.0 |

13.0 |

Φ1.5 |

3.0 |

3.0 |

|||||

|

BSC(R)0616 |

Φ6.0 |

16.0 |

Φ1.5 |

3.0 |

3.0 |

|||||

|

BSC(R)0820 |

Φ8.0 |

20.0 |

Φ2.5 |

4.0 |

4.0 |

|||||

|

BSC(R)1020 |

Φ10.0 |

20.0 |

Φ4.0 |

8.0 |

5.0 |

|||||

|

BSC(R)1225 |

Φ12.0 |

25.0 |

Φ5.0 |

10.0 |

6.0 |

|||||

|

BSC(R)1428 |

Φ14.0 |

25.0 |

Φ6.0 |

12.0 |

7.0 |

|||||

|

BSC(R)1625 |

Φ16.0 |

25.0 |

Φ6.0 |

12.0 |

8.0 |

|||||