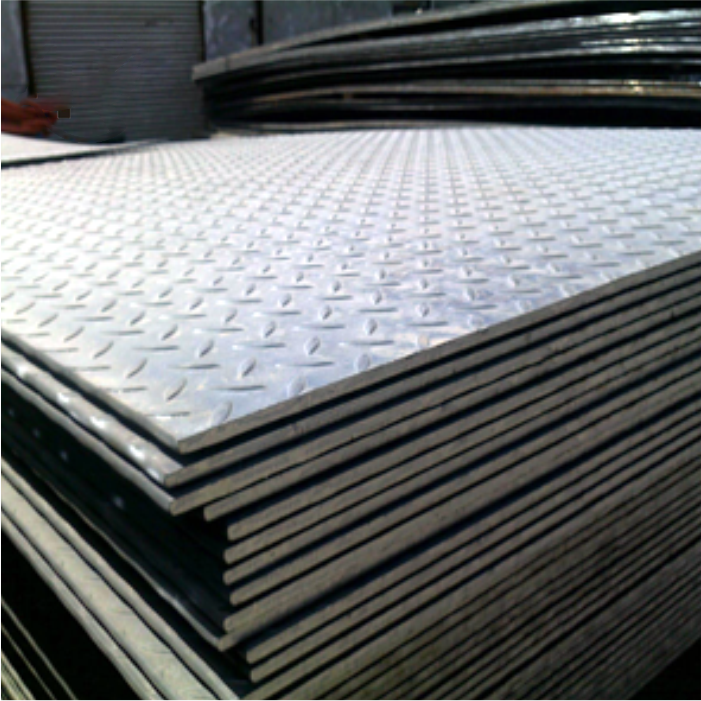

Building Construction ASTM A36 Q235B Q345B S235JR S355JR Hot Rolled Steel Plates Checkered Plate

Product Detail

Checkered steel plates, also known as diamond plates or floor plates, are steel sheets with raised diamonds or lines on the surface. These raised patterns provide a non-slip surface, making checkered steel plates ideal for applications where safety and traction are important, such as industrial walkways, catwalks, stairs, and vehicle floors.

Here are some key details about checkered steel plates:

Material: Checkered steel plates are typically made from carbon steel or stainless steel, but they can also be constructed from aluminum or other metals. The material choice depends on the specific application and environmental conditions.

Patterns: The raised patterns on checkered steel plates are often diamond-shaped or linear, with variations in size and spacing between the patterns. These patterns are designed to provide enhanced grip and stability, reducing the risk of slips and falls in industrial settings.

Thickness and Dimensions: Checkered steel plates come in various thicknesses and standard sizes, with common thicknesses ranging from 2mm to 12mm. The standard dimensions of the plates depend on the manufacturer and the intended use, but they are typically available in 4′ x 8′, 4′ x 10′, and 5′ x 10′ sizes.

Surface Finishes: The surface of checkered steel plates can be finished with a variety of treatments, including mill finish, painted, or galvanized. Each finish offers specific benefits in terms of corrosion resistance, aesthetics, and durability.

Applications: Checkered steel plates are widely used in industrial and commercial settings, including manufacturing facilities, construction sites, transportation vehicles, and marine environments. They provide an anti-slip surface that enhances safety and traction in areas where foot traffic or heavy machinery is present.

Fabrication and Customization: Checkered steel plates can be fabricated and customized to meet specific project requirements, including cutting to size, shaping, and adding additional features such as edge profiles or mounting holes.

|

Product Name

|

checkered steel plate

|

|

Material

|

Q235B,Q195B,A283 GR.A,A283 GR.C,A285 GR.A,GR.B,GR,C,ST52,ST37,ST35,A36,SS400,SS540,S275JR,

S355JR,S275J2H,Q345,Q345B,A516 GR.50/GR.60,GR.70,etc |

|

Thickness

|

0.1-500mm or as required

|

|

Width

|

100-3500mm or as customized

|

|

Length

|

1000-12000mm or as required

|

|

Surface

|

Galvanized coated or as customer requirements

|

|

Package

|

Waterproof pater, steel strips packed

Standard export package,suit for all kinds of transport,or as required. |

|

Payment terms

|

T/T L/C Western Union etc

|

|

MOQ

|

1ton

|

|

Application

|

steel plate are widely used in shipping building,engineer construction,mechanical manufacturing, the size of alloy steel sheet can be made according to clients required.

|

|

Delivery time

|

10-15 days after receive the deposit

|

Features

Application

Checkered steel plates typically feature raised patterns, such as diamonds or lines, on the surface. These patterns provide enhanced traction and slip resistance, making the plates suitable for industrial flooring, stair treads, vehicle ramps, and other applications where safety and stability are essential. Checkered steel plates are available in various materials, including carbon steel, stainless steel, and aluminum, and they come in different thicknesses and dimensions to meet specific project requirements. These plates are valued for their durability, corrosion resistance, and versatility in a variety of industrial and commercial settings.

Packaging & Shipping

The packaging for checkered steel plates typically involves securing them for transportation to ensure their protection and integrity during shipping and handling. Steel plates are often stacked and bundled together using steel straps or banding to prevent movement and maintain their shape. Additionally, protective materials such as plastic or cardboard may be used to shield the plates from scratches and other surface damage. The bundled plates are then usually loaded onto pallets for ease of handling and transport. Lastly, the entire package is often wrapped with plastic or shrink wrap to provide further protection against moisture and the elements. These packaging methods are designed to safeguard the checkered steel plates and facilitate their safe arrival at their destination.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company’s tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.