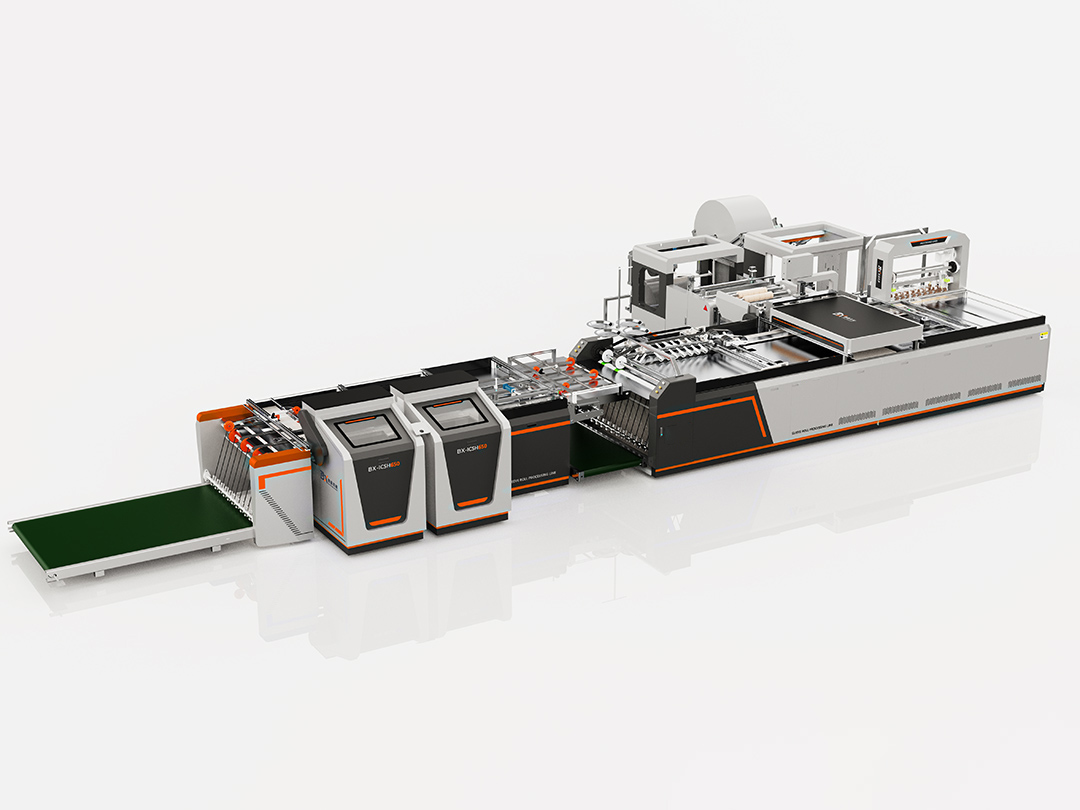

BX-CISH650 PE Film Liner Inserting And Hemming Machine

Specifications

| Item | Parameter |

|

Fabric Width(For liner inserting) |

350-750mm |

|

Fabric Width(For hemming) |

450-650mm |

|

Max Diameter of Fabric |

φ1200mm |

|

PE Film Width |

+20mm(PE Film Width Bigger) |

|

PE Film Thickness |

≥0.01mm |

|

Cutting Length of Fabric |

600-1200mm |

|

Cutting Accuracy |

±1.5mm |

|

Stitch Range |

7-12mm |

|

Production Speed(Liner inserting) |

20-38pcs/min |

|

Production Speed(Hemming) |

10-18pcs/min |

|

Power connection |

20+15=35KW |

|

Air consumption |

≥ 0.8 |

|

Machine weight |

About 6.5t |

|

Dimension (lay-out) |

10750x5350x1700mm |

Product Details

Application:

1. Liner can be fully sewn with PP Woven Bag.

2. Liner also can be not sewn / loose inside PP Woven Bag.

Original: China

Price: Negotiable

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, L/C

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

The different between Liner Inserting with Hemming and Liner Inserting Machine

Liner Inserting With Hemming Machine: There is an additional process compared to Only Liner Inserting. The bag opening can be folded and hemmed. Heming Unit offers two options for you to choose from: Heat Hemming and Ultrasonic. It can also be used separately from the complete bag machine and the loop mouth machine;

Equipment characteristics

1. Applicable for laminated or non-laminated bag,with liner or non-liner woven bag.

2. Auto align with PE liner and outer bag

3. Visual interface operation system

4. Full sets of Mitsubishi Electrical system

5. Hemmed or not hemmed are OK.

6. Auto sewing,hemming and counting

7. Can be used as cutting&sewing machine,liner inserting machine or liner inserting with hemming machine

8. Simply operation, can be ran by only one worker

Our Advantages

We has two factories of 10000 square meters and totally 100 employees to promise the Honed Tubes In Stock best quality control;

According to the cylinder pressure and inside diameter size ,different draulic cylinder honed tube Would be choosed ;

Our motivation is — customers’ satisfaction smile;

Our believing is — pay attention to every detail;

Our wish is —-perfect co-operation.

FAQ

You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, or QQ or WhatsApp or other instant ways, in case of any delays.

Usually we quote within 24 hours after we get your inquiry.

Yes. We have a professional team having rich experience in design and manufacturing. Just tell us your ideas and we will help to carry out your ideas.

Honestly, it depends on the order quantity and the season you place the order.Alway 60-90days based on general order .

We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.