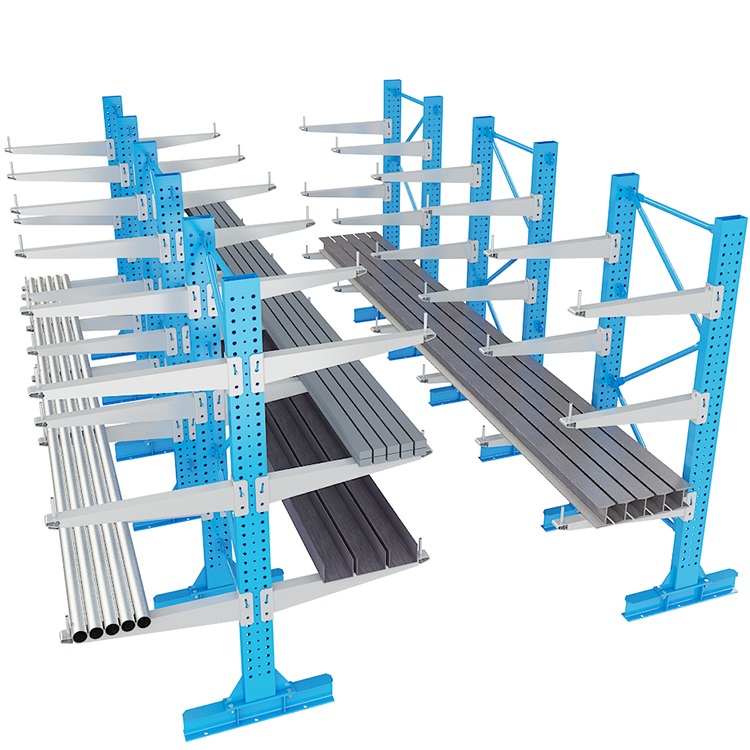

Cantilever Racking

Racking Components

Product Analysis

| Racking type: | Cantilever Racking | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 300-1500kg/arm |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 100mm/50mm | Place of origin | Nanjing, China |

| Application: | mechanical manufacture and architecture material supermarket enterprises | ||

① Storage method

Cantilever racks can be placed indoors or outdoors. For light duty cargo, it can be stored by manual easily. For heavy duty cargo, generally there are two storage methods: one is forklift, the other is bridge crane. Forklift storage is suitable for warehouse with large area, that allows forklift moves freely. While bridge crane storage is for warehouse with limited space, that is not available for forklift operation.

② Three categories

Based on loading requirement, cantilever is classified into four categories:

◆Light Duty Cantilever Racking

Upright: 150*60*2.5, adjusted by 50mm pitch.

Base: 12# I-steel

◆Medium Duty Cantilever Racking

Upright: 200*60*2.5, adjusted by 50mm pitch.

Base: 14# I-steel

◆Heavy Duty Cantilever Racking (most commonly used)

Upright: 300*90*3.0, adjusted by 100mm pitch

Base: 20# I-steel

◆H profile Cantilever Racking

Upright, base and arm specification are decided by loading requirement.

③ Cable Drum Racking

Cantilever racking structure can be specially designed as cable racking. In a cable racking system, a steel rod is placed through the centre of the drum to allow for horizontal storage. This also allows the cable to unravel when pulled on. Cable racking increases storage capacity by stacking cable drum on racking one by one.

④ With decking

Cantilever racking can be decked for storage of cargoes smaller than the spacing between towers, or easy-bending cargoes

Project cases