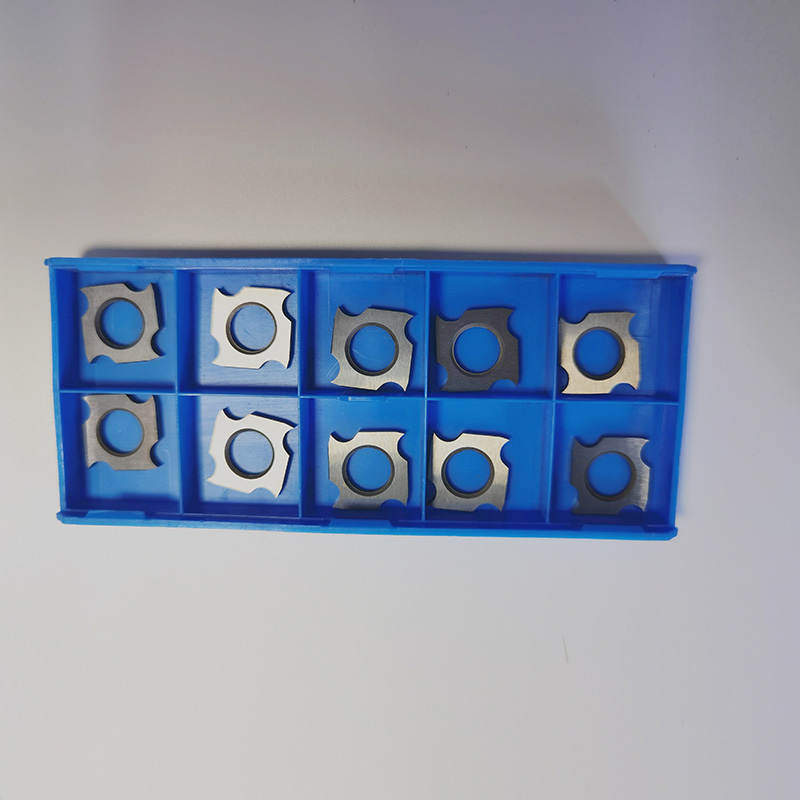

Carbide spur, grooving knives for woodworking-14x14x2 and 18×18

• The raw material is original tungsten carbide with ultra-fine grain.

• High strength and wear-resistance to make knife lifetime 40% longer

• Grind with sharp and high precision cutting edges.

There are various sizes and types available

1.Each product is produced after more than 13 steps to guarantees high precision.

2.For machine: equipped on spiral cutter head

3.More than 13 year experience with R&D capability.

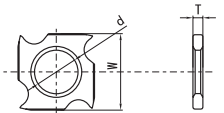

| L | W | T | d |

| 14 | 14 | 2 | 8.4 |

| 18 | 18 | 1.95 | 10.3 |

| 18 | 18 | 2.45 | 10.3 |

| 18 | 18 | 2.95 | 10.3 |

| 18 | 18 | 3.7 | 10.3 |

Different woodworking dimension of carbide spurs and grooving knives, planner knives for wood machinery are now available for different material types.

|

Grade |

ISO |

Co% |

Hardness |

Bending Strength |

performance |

|

HCK01 |

K01 |

4.0 |

93.9HRA |

1720N/mm² |

Original Sub-micron grain size. Excellent in wear resistance. |

|

HCK10UF |

K05-K10 |

6.0 |

92.5HRA |

2060N/mm² |

|

|

HCK30UF |

K20 |

10.0 |

91.5HRA |

2520N/mm² |

|

Application of grade for Carbide spur, grooving knives |

|

|

HCK10UF |

It can be applied to Chipboard and hard wood and plywood in woodworking. |

|

HCK30UF |

This grade is suitable for HDF and MDF board, especially excellent in cutting chipboard and hard solid wood. |

The carbide inserts and knives are made from high quality virgin carbide alloy for Industrial use. It has high precision ground and can provide longer lifetime. The quality has been approved by German, Italy, and American market because we not only just provide products to European customers, but also maintain long-term technical exchanges innovations with our customers and develop new products according to the market requirements.

If you need more information about our company, just feel free to contact us now.