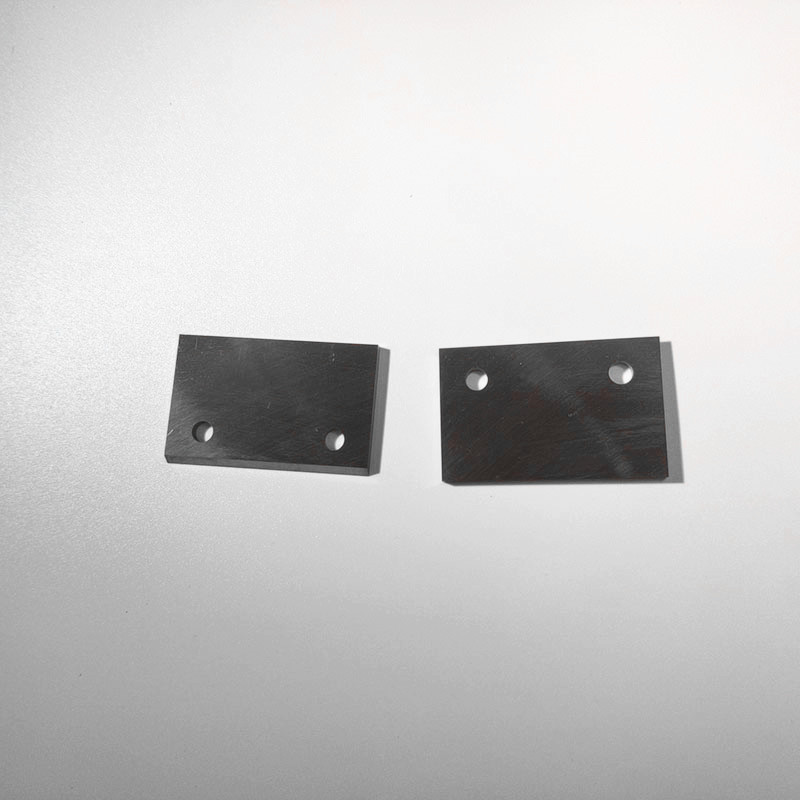

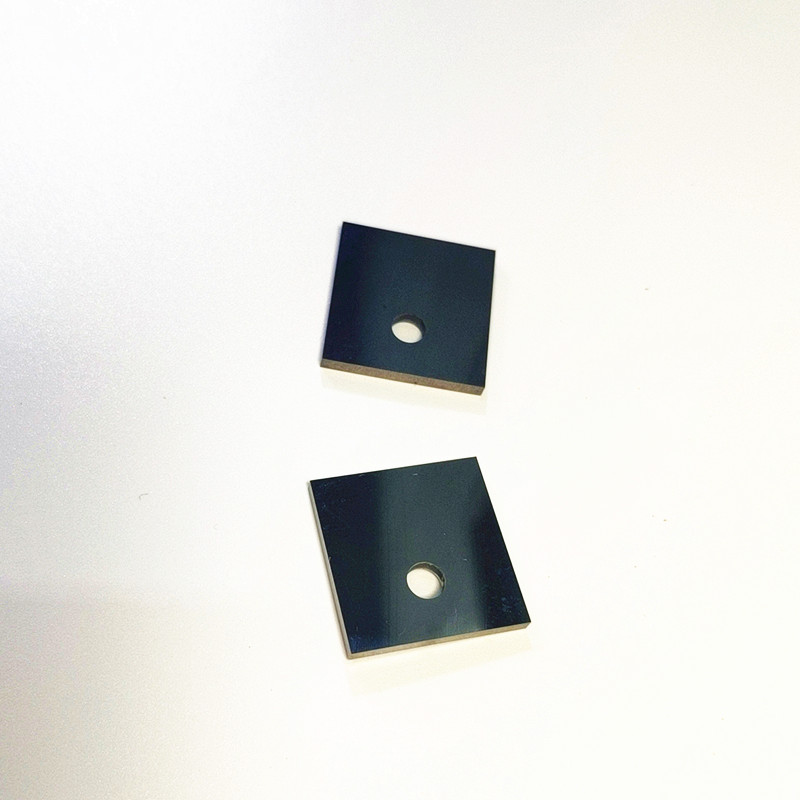

Carbide Turnover knives for woodworking cutter head 40×12, 30X12, 50X12

• The raw material of the carbide turnover knives is original tungsten carbide with ultra-fine grain.

• It can provide smooth and fine cuts every time

• Easy and fast to change on the woodworking cutter head

• Whole grinding with sharp and shining cutting edges.

• 4 precise ground cutting edges

• It is a cost-effective solution compared to replacing brazed router bits

There are various sizes and types available

1.Reliable quality and competitive price

2.Sharp enough and with high wear-resistance.

3.OEM is accepted, too.

| L | W | T | C | a | d |

| 24.7 | 12 | 1.5 | 14.00 | 35 | 4.1 |

| 25 | 12 | 1.5 | 14.00 | 35 | 4.1 |

| 29.5 | 12 | 1.5 | 14.00 | 35 | 4.1 |

| 30 | 12 | 1.5 | 14.00 | 35 | 4.1 |

| 35 | 12 | 1.5 | 26.00 | 35 | 4.1 |

| 40 | 12 | 1.5 | 26.00 | 35 | 4.1 |

| 50 | 12 | 1.5 | 26.00 | 35 | 4.1 |

| 60 | 12 | 1.5 | 26.00 | 35 | 4.1 |

Different woodworking carbide turnover knives grade are now available for different material types such as softwood/ hardwood MDF/solid surface and micro-finish for general purpose.

|

Application of grade for carbide reversible knives |

|

|

HCK01 |

This grade for carbide reversible knives can be used for HDF and MDF, chipboard in Furniture Industry |

|

HCK10UF |

It can be applied to Chipboard and hard wood and plywood in woodworking. |

|

HCK30UF |

This grade is suitable for HDF and MDF board, chipboard, and hard solid wood and plywood, especially excellent in cutting chipboard and hard solid wood. |

The carbide reversible knives can be used on tools are as below: woodworking cutter head, woodworking spiral cutter shaft, single-axis milling machine, router, woodworking machine, planning, and other woodworking machine tools.

Need other sizes?

Please contact us for application consulting.