Cartridge TD025M 28231-27000 49173-02412 Hyundai Elantra D4EA

Product Video

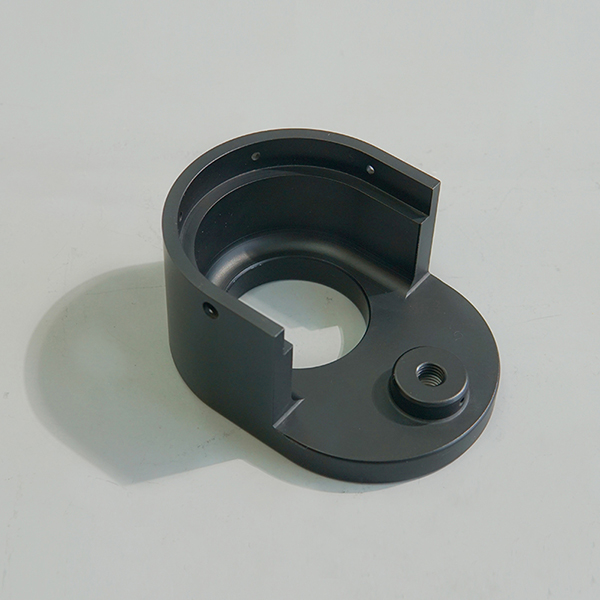

Product Description

| Part Number | 49173-08401 |

| Previous Version | 4917308401, 49173-08405 |

| OE number | 1401402906, 1000050103 |

| Turbo Model | TD025M-03-09T-3.3, TD025 |

| Manufacturer | Mitsubishi |

| Bearing housing | (1401402453, 1900011158)(Oil Cooled) |

| Turbine Wheel | 49173-00011 (Ind. 37. mm, Exd. 31.47 mm, 12 Blades)(1401402436, 1100016132) |

| Rotor Assembly | (2300050031) |

| Comp. Wheel | (Ind. 34.08 mm, Exd. 44.04 mm, 6+6 Blades, SuperBack)(1401402405, 1200016205) |

| Back plate | (Superback)(1401402300, 1800016052/046) |

| Heat shield Number | (1401402341, 2030016065) |

| Repair Kit | (1401402754, 5000050028)(F/back) |

Applications

2000- Hyundai Elantra 2.0 CRDi Engine D4EA

2000- Hyundai Santa Fe 2.0 CRDi Engine D4EA

2000-08 Hyundai Trajet 2.0 CRDi Engine D4EA

2000-04 Hyundai Tucson 2.0 CRDi Engine D4EA

2002-06 KIA Carens II 2.0 CRDi Engine D4EA

Mitsubishi TD025M-03-09T-3.3 Turbos:

49173-02401, 49173-02410, 49173-02412

Mitsubishi TD025 Turbo:

49173-02301

OE number

2823127000, 28231-27000

Related Informations

Can I upgrade my existing turbo?

Yes. Most turbo upgrade facilities offer improvement services. State your turbo, its current disappointments, and improvements you would like to see. They might offer services that can save you from buying a new turbo. Though not an all inclusive list, possible services include:

a. Port and polish: Includes heavy porting of exhaust housing, removal of flow obstructions, smoothing of the factory material, and reduction of internal angles to alter flow and evacuation. Entrance to turbo housing (where the exhaust enters the unit) is also heavily ported, removing flow obstructions and smoothing exhaust path. Wastegate pass-through from exhaust housing is also ported, increased slightly in size, and any flow obstructions removed. The most significant improvement with this service is the decreased spool time. Another improvement is the additional torque in the lower RPM band as seen in this graph. Lack of low end torque is a common complaint with 2.0L motors.

b. Internal ported and polish: This opens up the area where the air exits the compressor housing. The turbo has between 1 & 2 mm of material removed, then the rough casting edges are smoothed out. You will pick up a fraction of a HP but get better response.

c. Light clip: Clipping removes part of the turbine wheel. This allows air to pass over it faster. It will help out with high boost (16.5 PSI +) situations but will slow down spoolup.

d. Coating: Ceramic coatings keep heat inside the turbo for increased thermal efficiency.

e. Larger waste gate flapper: New technique where a large wastegate flapper is installed in place of the stock unit. The large piece covers a specially ported, larger waste gate hole in an effort to combat boost creep.

f. Changing internal turbo components: This service depends on the turbo. Generally speaking it means things such as replacing the compressor wheel with a larger unit for increased performance, changing the wastegate spring, and other internal improvements.