Cast die mold for metal products

Product Introduction

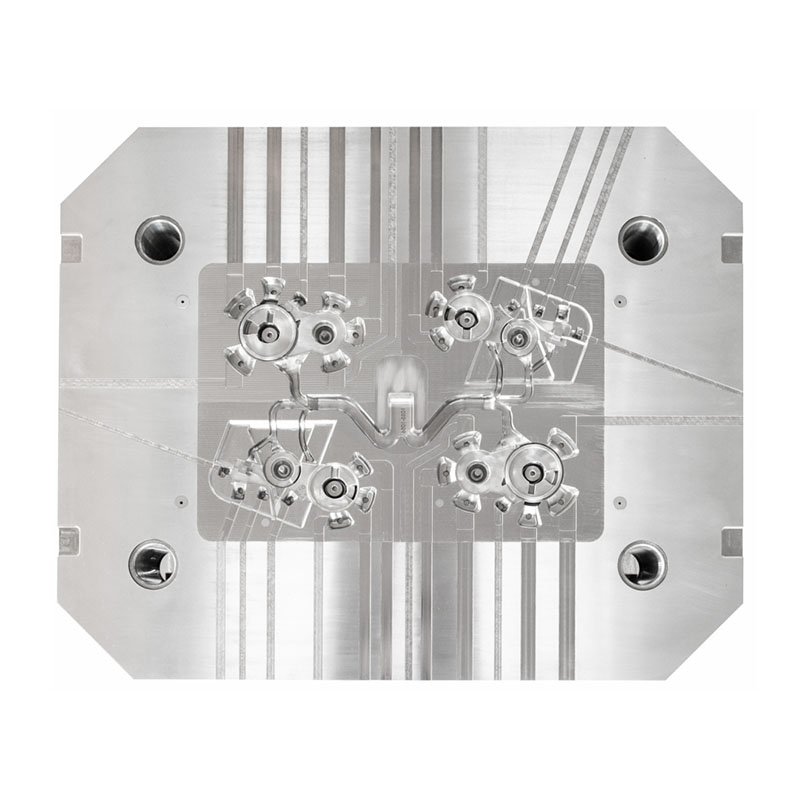

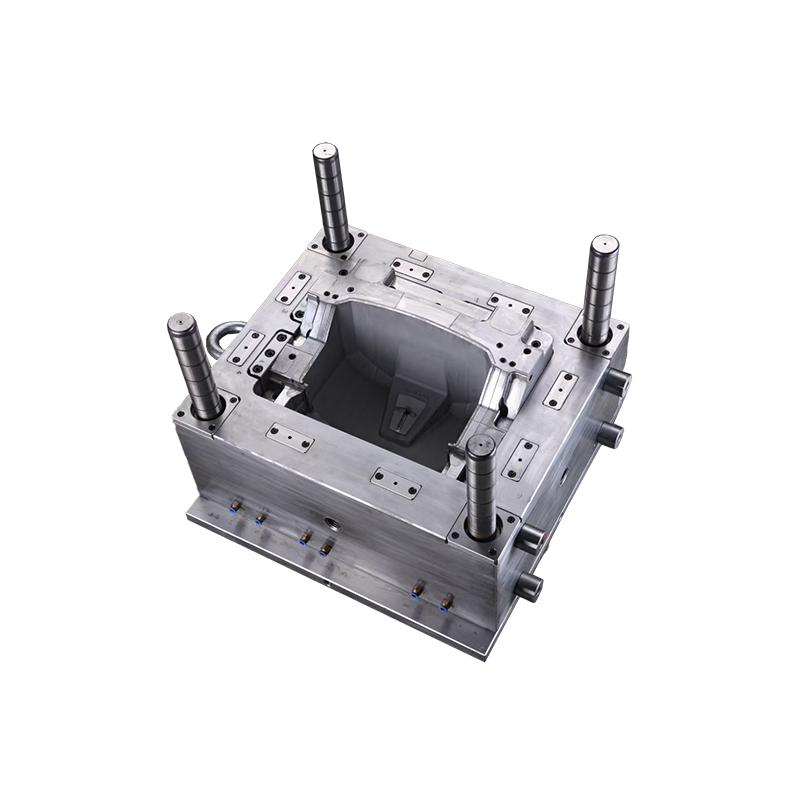

Mold Structure

By mold base: panel, A plate, B plate, ejector pin plate, ejector pin cover plate, square iron (mold angle), bottom plate.

Mold core part: male mold core, female mold core, slider.

Cooling system: water circuit.

Mechanism: sprue sleeve, ejector pin, guide pillar guide sleeve, guide block, precise positioning, counter, inclined guide pillar, wear resistant block, positioning ring, ejector pin limit switch, dust shield, EGP.

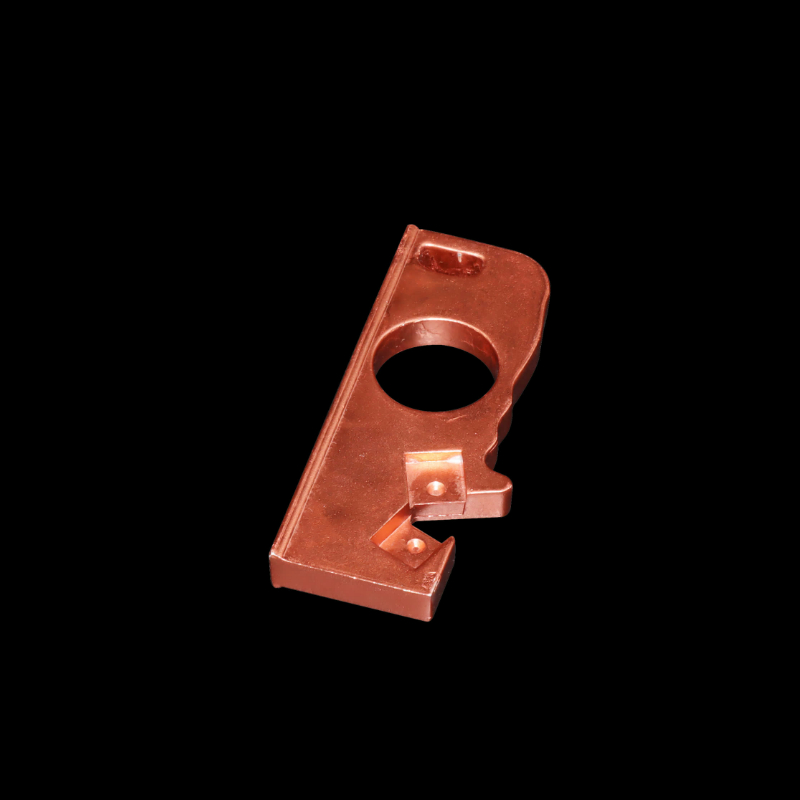

Cast die mold, also known as die casting mold, is a type of mold used in the manufacturing of metal parts through the process of die casting. It is made from high-quality materials such as steel, aluminum, and zinc, and is an important tool in the production of high-quality metal parts.The main advantage of using a cast die mold is its ability to produce high precision and high-quality parts with excellent surface finishes. It also offers high production efficiency and cost-effectiveness, making it ideal for mass production of metal parts.When using a cast die mold, it is important to consider the material being used and the intricacies of the design.

The mold needs to be properly designed and constructed to ensure that it can withstand the high pressures and temperatures involved in the die casting process.Cast die molds are suitable for use in various industries, including automotive, aerospace, and electronics. They can be used to produce a range of metal parts, from simple components such as brackets and housings to complex parts such as engine blocks and transmission cases.In terms of after-sales service, reputable cast die mold manufacturers provide comprehensive technical support, including mold maintenance and repair services. They also offer warranties to ensure customer satisfaction and peace of mind.Cast die molds are typically shipped in sturdy and protective packaging to ensure safe transport. They can be shipped by air, sea, or land, depending on the destination and the customer’s requirements.In conclusion, cast die molds are a vital component in the production of high-quality metal parts. They offer high precision and efficiency and are suitable for use in a wide range of industries. Proper design, construction, and maintenance are important to ensure optimal performance and longevity. Reputable manufacturers offer comprehensive after-sales services and warranties to ensure customer satisfaction.