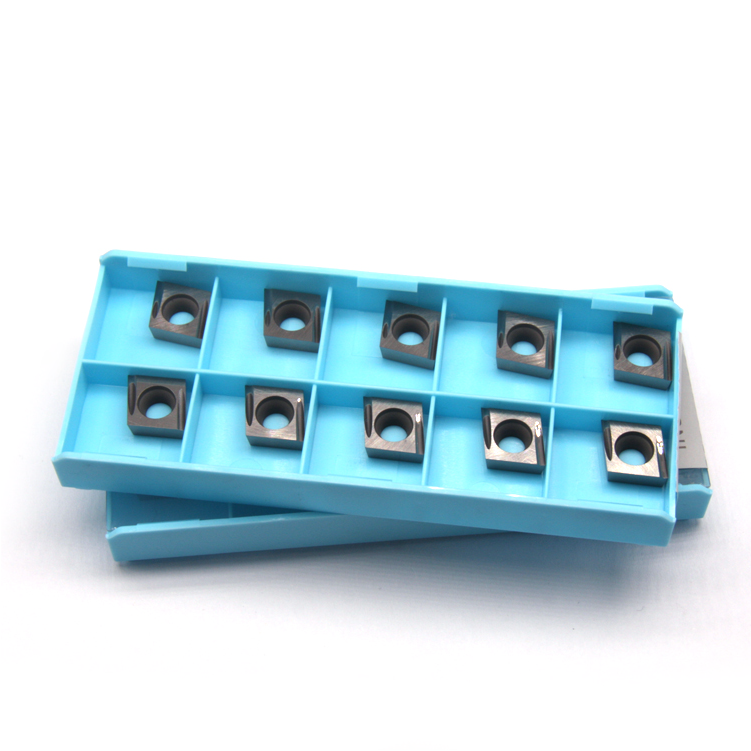

CCGT09T302FL-1U PV4312 Carbide PVD Coated Inserts Hard Material Machining Finishing

Product Detail

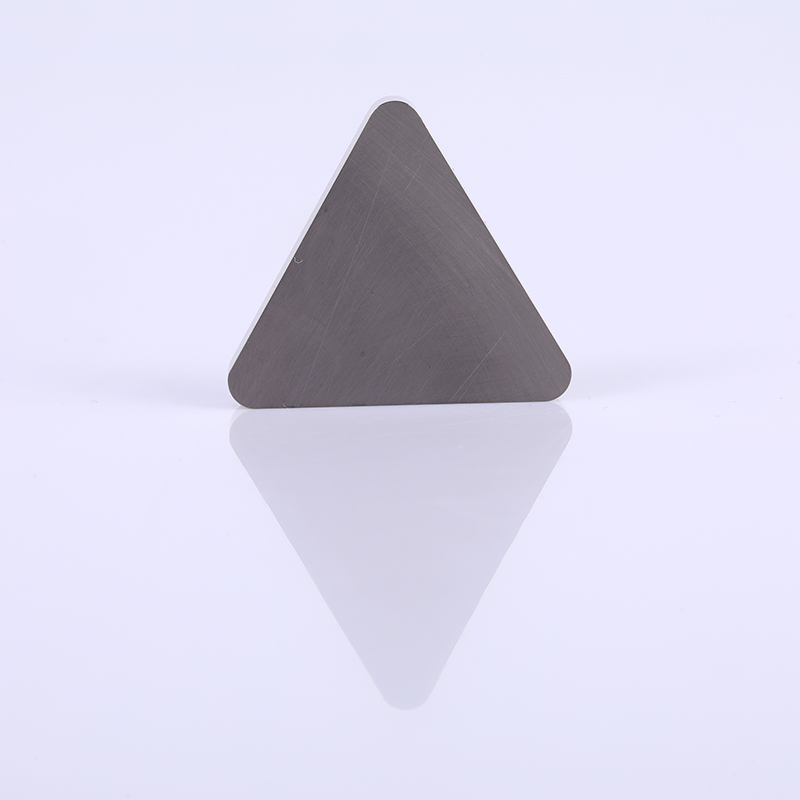

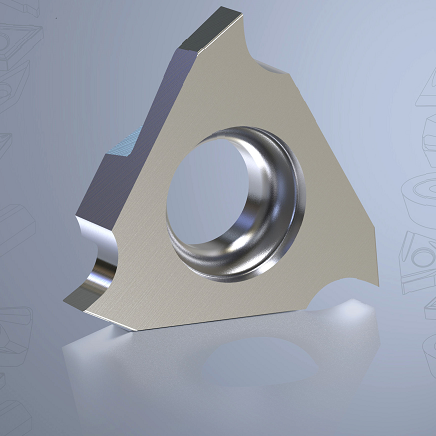

The chip breaker 1U makes low cutting force machining be available thanks to reliable chip control even when the depth of cut varies at low feed rates. It is a carbide PVD coated insert with inscribed circle diameter of 9.525mm, 3.97mm thick, 0.2mm nose radius, indexing accuracy according to ISO-tolerance class-G.

PVD coatings result in extreme surface hardness, low coefficient of friction, anti-corrosion, and wear resistance properties. Our PVD coated grade PV4312 makes the carbide inserts more strong and it is suitable for hard material up to HRC55, Superalloy, titanium alloyed machining.

Features

-Perfect chip control performance

-Low coefficient of friction

-Suitable for hard material machining up to 55HRC

- Excellent surface roughness

- Low cutting force, low noise machining.

Applications

PVD coatings result in extreme surface hardness, low coefficient of friction, anti-corrosion, and wear resistance properties. Our PVD coated grade PV4312 makes the carbide inserts more strong and it is suitable for hard material up to HRC55, Superalloy, titanium alloyed machining.

Parameters

| Insert Type | CCGT09T302FL-1U |

| Grade | PV4312 |

| Material | WC+Gu Carbide |

| Hardness | 4200HV |

| Density(g/cm³) | 14.2 |

| Antioxidant temperature | 1000 |

| Workpiece | hard material up to HRC55, Superalloy, titanium alloyed |

| Machining method | Finishing |

| Application | CNC turning |

FAQ

Q:Are you trading company or manufacturer?

A:We are manufacturer.

Q: What kind of payment terms you accept?

A:T/T,West Union,Paypal,Credit Card and other main terms.

Q:How can you guarantee the production quality?

A:Our company is based on ISO9001,we have more than 30 years experience of QC team and strictly quality control system.However,90 days of free change is provided.

Q:What kind of cutting tools do you manufacture?

A:We manufacture a wide range of products including cermet inserts, endmill, blanks, rods, plates and customized products.

Q:What about the shipment way?

A: We can arrange shipment via DHL, FEDEX, TNT, UPS upon customer’s request.

Q:Do you provide samples?Is it free or extra?

A:Yes,we could offer the samples for free.