Cemented Carbide Rotary Burrs Tree Type

Cemented Carbide Rotary Burrs Tree Type

Due to the nature of tungsten carbide and its extreme hardness, the range of applications and uses for carbide burrs is extensive. Carbide burrs are widely used for metalwork, tool making, engineering, model engineering, wood carving, jewellery making, welding, chamfering, casting, deburring, grinding, cylinder head porting and sculpting. And are used in the aerospace, automotive, dental, metal sculpting.

Features of Cemented Carbide Rotary Burrs

High speed rotate and high efficiencyClean, smooth finishing and good cutting qualityGreat for deburring, shaping, smoothing welds, enlarging holes, carving and finishingProcessing for many metalsLong lifetime

Cut Selection Guide of Cemented Carbide Rotary Burrs

|

Material |

Cut Type |

||

|

Single Cut |

Double Cut |

Alum Cut |

|

|

Aluminium, Plastic |

|

|

× |

|

Brass, Copper, Cast Iron, Bronze |

× |

× |

|

|

Unhardened Steel |

× |

× |

|

|

Hardened Steel, Stainless Steel, Nimonic Alloy, Titanium |

× |

× |

|

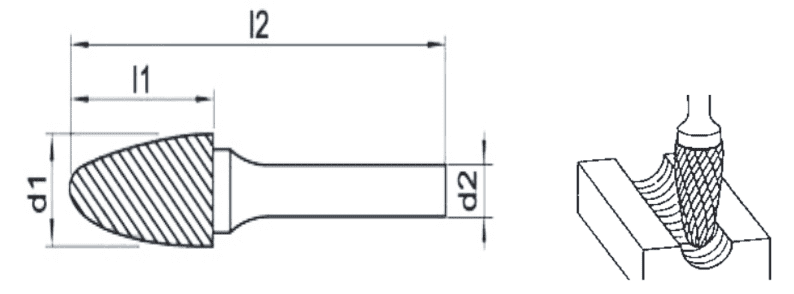

Dimension of Cemented Carbide Rotary Burrs Tree Type

Standard is 6mm shank, inch length, 3mm shank, long shank and customized are all available.

All in mm

|

Order No. |

Head Diameter |

Head Length |

Shank Diameter |

Overall Length |

|

F0618M06 |

6 |

18 |

6 |

63 |

|

F0818M06 |

8 |

18 |

6 |

63 |

|

F1020M06 |

10 |

20 |

6 |

65 |

|

F1225M06 |

12 |

25 |

6 |

70 |

|

F1425M06 |

14 |

25 |

6 |

70 |

|

F1625M06 |

16 |

25 |

6 |

70 |

More information please click here