Cemented Carbide Saw Tips

Cemented Carbide Saw Tips

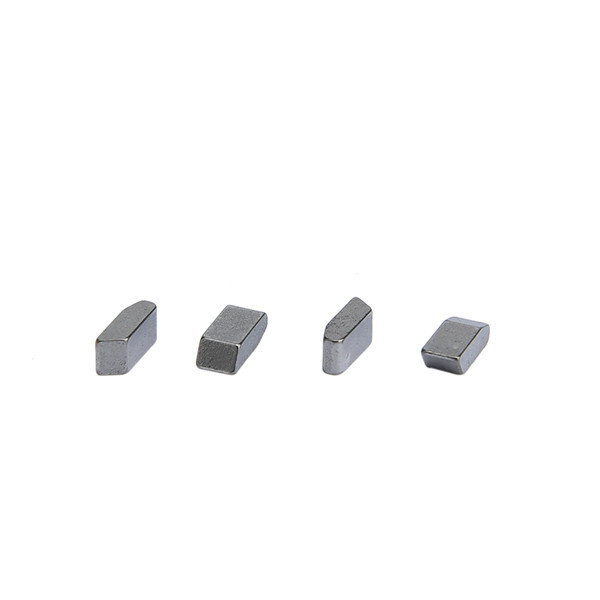

The Cemented Carbide Saw Tips are brazed on to circle saw blades, widely used for wood and metal cutting applications. Due to cutting conditions have vary quite changes, we supply a wide range of carbide saw tip shapes(as ball, cylinder, profiles) for customers’ cutting needs.

Cemented carbide saw tips can manufacture as customer specification. Our technicists will recommend which carbide carbide grade and size to satisfy customers sawing conditions.

Features of Cemented Carbide Saw Tips

High performance and good wear resistanceExcellent heat stability and chemical stability, well perform under high temperatureCustomized design and narrow tolerance are availableReduced grinding operation costs, ten and twenty lifetime longer than steel saw tipsOEM/ODM, customization is availableManufacturer supply, factory direct supply, nice priceISO 9001 Certification

Recommend Grade of Cemented Carbide Saw Tips

|

MY Grade |

MU10 |

MK05 |

MK10 |

MK15 |

MK20 |

MF10 |

MF20 |

|

|

Grace |

YG6X |

YG6X |

YG6 |

YG7 |

YG8 |

YG6 |

YG8 |

|

|

ISO Grace |

K10 |

K10 |

K10 |

K10-K20 |

K20 |

K10 |

K20 |

|

|

Co |

% |

6.3 |

6.3 |

6 |

7 |

8 |

6 |

8 |

|

Grain Size |

μm |

0.8 |

1 |

1.2 |

1.2 |

1.3 |

1.2 |

1.3 |

|

Density |

G/m³ |

14.85 |

14.8 |

14.8 |

14.75 |

14.7 |

14.85 |

14.85 |

|

Hardness |

HRA |

93 |

92 |

91.5 |

91 |

90 |

90.5 |

90 |

|

HV30 |

1800 |

1610 |

1530 |

1470 |

1350 |

1410 |

1350 |

|

|

T.R.S. |

Mpa |

2800 |

2800 |

2800 |

2800 |

3000 |

2800 |

3000 |

Other grades please click here and we can also offered by customs specific requirements.

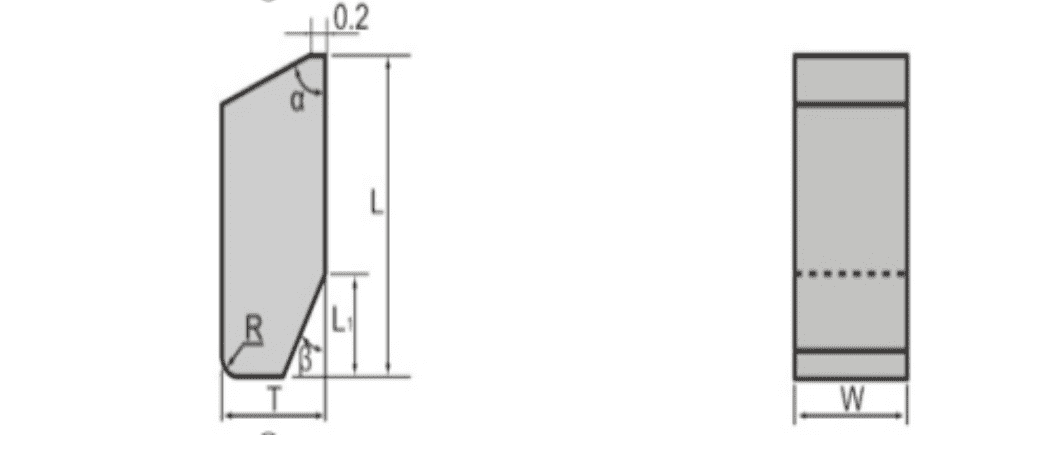

Dimensions of Cemented Carbide Saw Tips

![6L@@W$J(YW~SJ[DB9[]ZB%1](/uploads/c5e31646.png)

Any other sizes and customized are available

All in mm

|

L |

W |

T |

α° |

β° |

r° |

|

5 |

1.8 2.2 2.4 2.8 3.2 3.5 4.0 |

1.5 |

28 |

45 |

0 |

|

5.5 |

2.0 2.3 2.8 3.4 5.5 |

1.5 |

20 |

75 |

0 |

|

6 |

2.0 2.4 2.6 2.8 3.0 3.2 3.5 3.8 4.5 5.0 |

1.8 |

28 |

45 |

0 |

|

6 |

2.3 2.5 2.7 3.0 5.0 |

1.8 |

20 |

65 |

4 |

|

6.5 |

1.9 2.2 2.7 3.3 6.5 |

1.6 |

28 |

70 |

5 |

|

6.5 |

2.6 3.0 3.2 3.4 3.5 3.8 4.0 4.2 6.0 |

2 |

30 |

65 |

5 |

|

7 |

2.0 2.3 2.5 2.7 3.2 3.3 3.6 3.8 4.4 6.0 |

2 |

28 |

70 |

5 |

|

7 |

2.8 3.0 3.2 3.4 3.7 4.0 6.5 7.0 |

2.3 |

20 |

76 |

0 |

|

7.5 |

2.0 2.2 2.4 2.8 3.0 3.2 3.6 3.8 6.0 |

2 |

28 |

70 |

5 |

|

7.5 |

2.8 3.2 3.5 3.7 4.5 5.0 5.6 6.0 6.5 |

2.4 |

30 |

50 |

0 |

|

8 |

2.8 3.0 3.3 3.5 3.8 4.1 4.2 4.6 5.0 5.2 5.5 10.0 |

2.5 |

28 |

70 |

5 |

|

8 |

3.6 4.1 4.3 4.6 4.8 5.0 5.1 5.5 6.0 |

3 |

25 |

45 |

0 |

|

8.5 |

2.8 3.0 3.3 3.4 3.5 3.6 3.8 4.1 4.2 4.3 4.6 5.0 |

2.5 |

28 |

70 |

5 |

|

9 |

3.1 3.3 3.5 3.6 3.8 4.3 4.5 4.7 5.2 5.5 5.8 6.0 |

2.7 |

28 |

70 |

5 |

|

10 |

3.5 3.7 3.9 4.0 4.3 4.5 4.7 5.0 5.5 6.0 6.5 7.0 7.5 10.0 |

2.8 |

28 |

70 |

5 |

|

10 |

3.5 3.8 4.3 4.5 4.7 4.8 5.0 5.3 5.4 5.5 6 |

3 |

15 |

72 |

0 |

|

10.5 |

3.0 3.5 3.8 7.0 |

2.3 |

28 |

70 |

5 |

|

10.5 |

3.0 3.4 3.5 3.6 3.8 4.1 4.3 4.5 4.6 4.7 4.8 5.0 5.3 5.5 5.6 6.0 6.5 7.0 7.5 14.5 |

3 |

28 |

70 |

5 |

Tolerance of Cemented Carbide Saw Tips

All in mm

All in mm

|

Length |

Height |

Thickness |

Radius |

||

|

L |

Width |

TOL |

TOL |

TOL |

TOL |

|

≤5 |

W≤2 |

±0.05 |

+0.06 -0.04 |

±0.05 |

±0.08 |

|

2<W<3.5 |

±0.06 |

||||

|

3.5≤W≤5 |

±0.07 |

||||

|

5—7 |

W≤2 |

±0.06 |

+0.08 -0.04 |

±0.05 |

±0.08 |

|

2<W<4 |

±0.07 |

||||

|

4≤W≤6 |

±0.08 |

||||

|

7—9 |

W≤3 |

±0.08 |

+0.08 -0.04 |

±0.06 |

±0.10 |

|

3<W<5 |

±0.10 |

||||

|

5≤W≤8 |

±0.12 |

||||

|

9—13 |

W≤3.5 |

±0.10 |

+0.08 -0.04 |

±0.06 |

±0.12 |

|

3.5<W<6 |

±0.12 |

||||

|

6≤W≤10 |

±0.15 |

||||

|

13—16 |

W≤4 |

±0.12 |

+0.10 -0.05 |

±0.07 |

±0.14 |

|

4<W<7 |

±0.15 |

||||

|

7≤W≤14 |

±0.18 |

||||

|

16—20 |

W≤4.5 |

±0.12 |

+0.10 -0.10 |

±0.08 |

±0.16 |

|

4.5<W<7 |

±0.18 |

||||

|

7≤W≤15 |

±0.20 |

||||