Cemeted Carbide Rotary Burrs

Cemented Carbide Rotary Burrs

Due to the nature of tungsten carbide and its extreme hardness, the range of applications and uses for carbide burrs is extensive. Carbide burrs are widely used for metalwork, tool making, engineering, model engineering, wood carving, jewellery making, welding, chamfering, casting, deburring, grinding, cylinder head porting and sculpting. And are used in the aerospace, automotive, dental, metal sculpting.

Features of Cemented Carbide Rotary Burrs

High speed rotate and high efficiencyClean, smooth finishing and good cutting qualityGreat for deburring, shaping, smoothing welds, enlarging holes, carving and finishingProcessing for many metalsLong lifetime

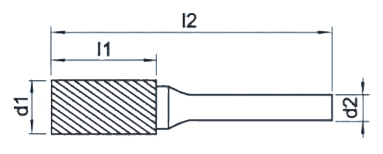

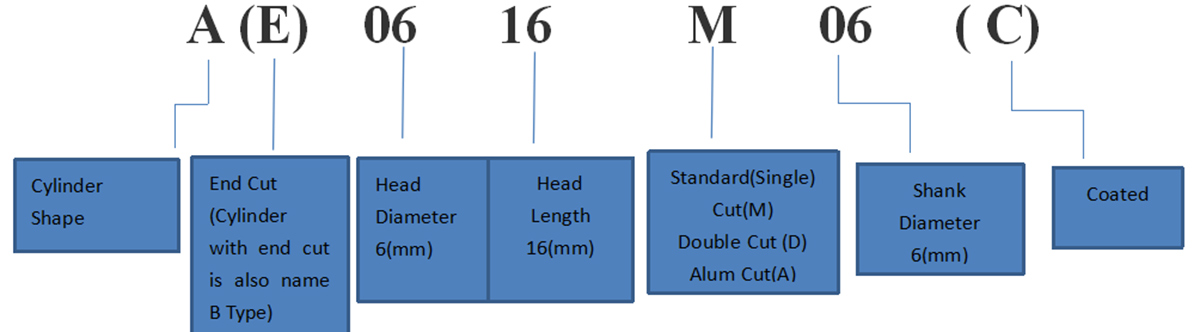

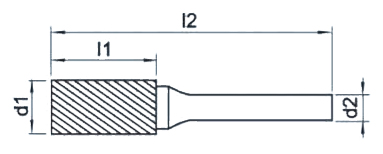

How to Order:

Standard product is 6mm shank, without end cut, standard(single) cut.

Inch Standard, 3mm shank, long shank and customized are all available.

Different Cut Types of Cemented Carbide Rotary Burrs

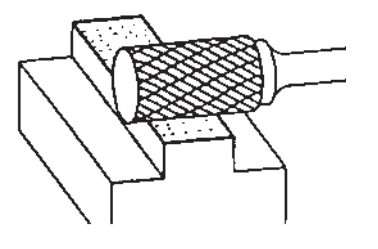

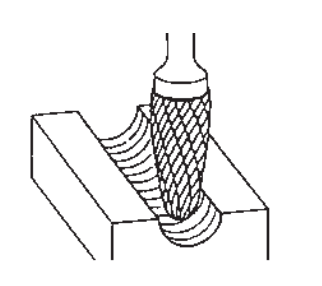

Standard Cut

Standard cut is a general purpose tool designed for cast iron, steel, some copper and brass, and other ferrous materials.

It will give good material removal and good work piece finishes.

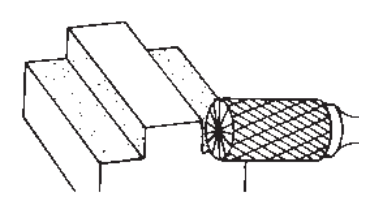

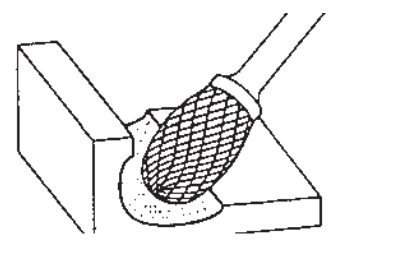

Double Cut

Double Cut allows for rapid stock removal in harder materials. The addition of the left hand flutes reduces the pulling action, allowing better operator control.

It reduces the size of the chips and can be used at slower than normal speeds.

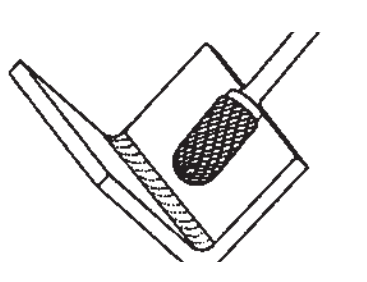

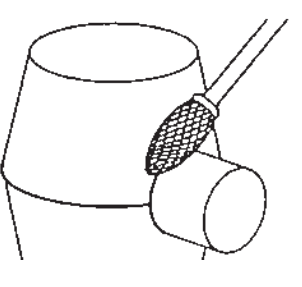

Alum Cut

Double Cut is designed to have wider chip space with relief angle. More suitable application to non-ferrous metals.

For use on Aluminium and softer materials. Faster stock removal with no clogging.

Cut Selection Guide of Cemented Carbide Rotary Burrs

|

Material |

Cut Type |

||

|

Single Cut |

Double Cut |

Alum Cut |

|

|

Aluminium, Plastic |

|

|

× |

|

Brass, Copper, Cast Iron, Bronze |

× |

× |

|

|

Unhardened Steel |

× |

× |

|

|

Hardened Steel, Stainless Steel, Nimonic Alloy, Titanium |

× |

× |

|

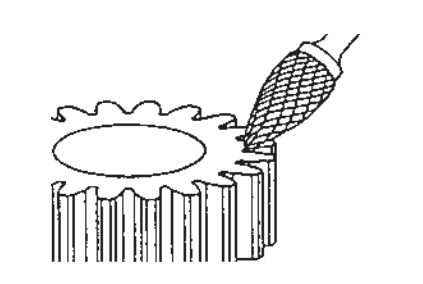

Application of Different Type Cemented Carbide Rotary Burrs

|

MODEL |

ITEM |

APPLICATION |

|

|

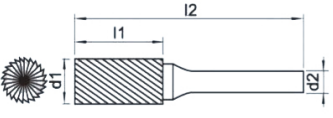

Cylinder Shape(A Type) |

|

Deburring |

|

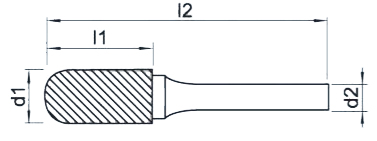

Cylinder With End Cut(B Type) |

|

Interior contour work, peripheral and face milling |

|

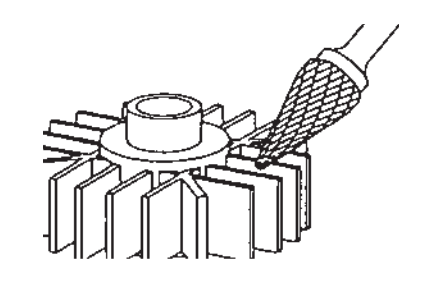

Ball Nose Cylinder(C Type) |

|

Deburring, contouring |

|

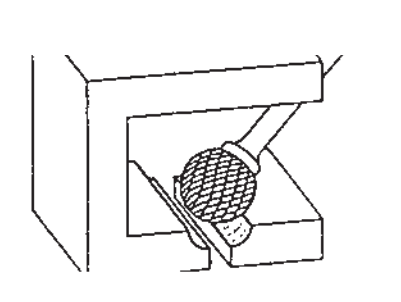

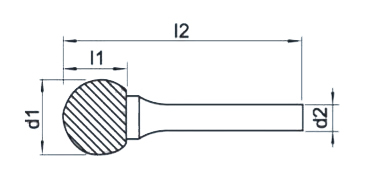

Ball Shape(D Type) |

|

Contouring, bore deburring, milling in preparation of build-up welding |

|

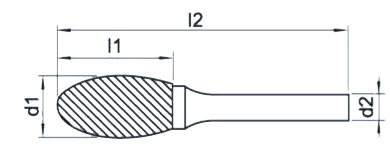

Oval Shape(E Type) |

|

Contouring |

|

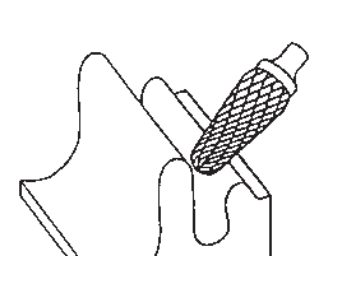

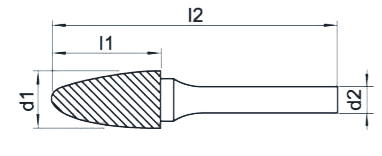

Tree(F Type) |

|

Interior contour work, peripheral and face milling |

|

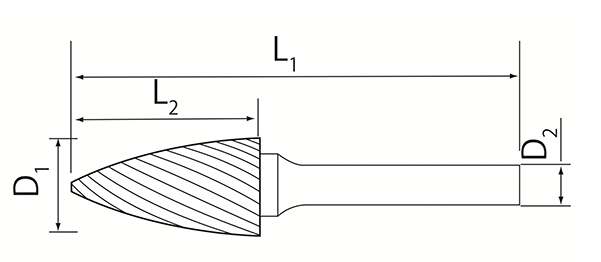

Pointed Tree(G Type) |

|

Work on narrow contours, Milling of acute-angled surfaces |

|

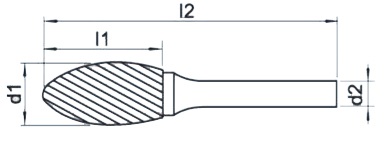

Flame Shape(H Type) |

|

Work on narrow contours |

|

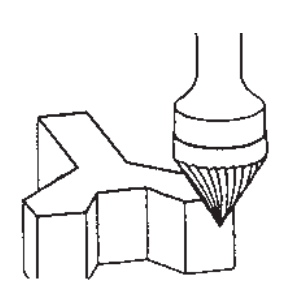

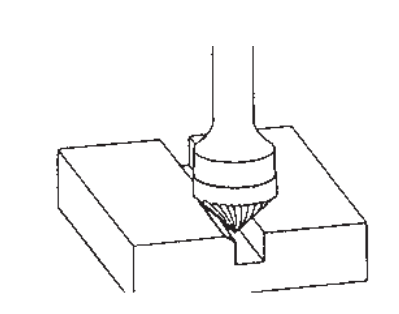

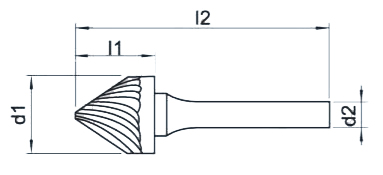

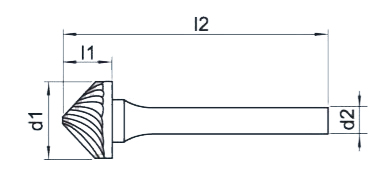

60°Countersink(J Type) |

|

Machining of acute-angled areas, countersinking; beveling / chamfering at defined angles

|

|

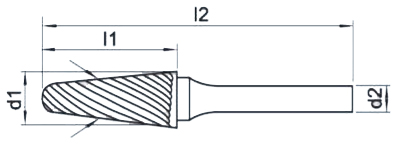

90°Cone(K Type) |

|

Machining of acute-angled areas, countersinking; beveling / chamfering at defined angles |

|

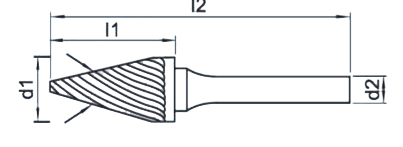

Ball Nose Cone(L Type) |

|

Work on narrow contours and surfaces, surface machining |

|

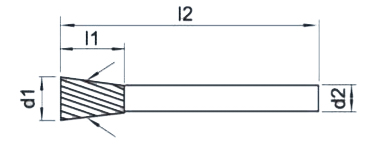

Cone Shape(M Type) |

|

Work on narrow contours and surfaces, surface machining |

|

Inverted Cone(N Type) |

|

Edge machining from the rear in hard to reach areas |