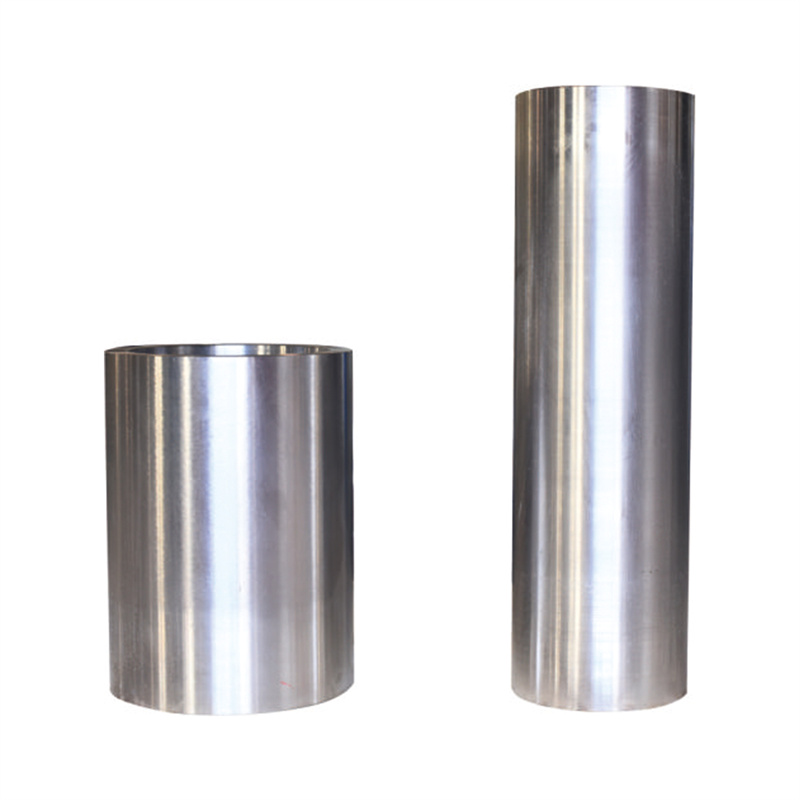

Centrifugal Casting Stainless Steel Sleeve & Liner

Weizhen Hi-techis a leading stainless steel foundry from China with horizontal and vertical centrifugal casting, sand casting, 3D sand printing, machining and NDT testing capabilities.Weizhenhas the industrial know-how and experience in the manufacture of a vast range of stainless steel casting parts.Weizhenis now a reliable and trust-worthy partner of major machinery and equipment manufacturers around the world.

Product Specification

| Product Name | Stainless Steel Pipe/Tube/Cylinder |

| Casting Method | Centrifugal casting |

| Material Options | 304, 304L, 316, 316L, SAF2304, SAF 2205, SAF2507 |

| Material Standard | GB, ASTM, AISI, EN, DIN, BS, JIS, NF, AS, AAR, |

| Casting Weight | 100-15000 kg |

| Casting Size | Max Diameter: 1600 mm, Max Length: 4200 mm |

| Casting Dimension Tolerance | CT9 – CT12 |

| Casting Surface Roughness | Ra 12.5∽Ra50 um |

| Machining Surface Roughness | Ra0.8 ~ 6.3um |

| Heat treatment | Annealing, normalizing, quenching or tempering |

| Finish | As cast, rough machined, finish machined. |

| Service Available | OEM & ODM |

| Certification | CE, ISO9001:2015, ISO19600:2014, ISO14001:2015, ISO45001:2018, |

| Application | Decanter centrifuge, pusher centrifuge, disc separator, separation machine etc. |

Advantages Of Centrifugal Cast Stainless Steel Parts

Resistance Properties:Centrifugal casting shaft sleeves can be crafted from materials with excellent corrosion resistance, making them suitable for use in corrosive environments where durability is paramount.

Improved Strength:Stainless steel parts produced through centrifugal casting tend to have improved tensile strength and wear resistance as forged parts compared to other casting methods.

Uniform Grain Structure:Centrifugal casting produces a uniform grain structure in the stainless steel, which results in improved mechanical properties and enhanced performances for the stainless steel parts.

High Purity:The centrifugal force helps eliminate air bubbles and impurities in the molten metal, resulting in a high-purity, defect-free product.

High Precision:The rotation speed and the duration of the casting process can be adjusted to control the wall thickness of the stainless steel parts, allowing for precise size customization.

Various Material Choices:Various types of stainless steels could be chosen in centrifugal casting to meet specific requirements for corrosion resistance, heat resistance, and/or wear resistance etc.