China Automotive PCBA Manufacturer

Product Description

- As technology continues to advance, the demand for electronic manufacturing services in the automotive industry continues to grow. New and innovative products are constantly being developed to meet the needs of consumers. The requirements for electronics in the automotive industry are very stringent and the highest quality standards must be adhered to in order to ensure safety and reliability.

PCBA Capabilities

|

Material |

FR4, (High Tg FR4,General Tg FR4,Middle Tg FR4),Lead-Free Solder Sheet,Halogen Free FR4, Ceramic Filling Material,PI Material,BT Material,PPO,PPE etc. |

|

Board Thickness |

0.11-0.5mm |

|

Max.Copper Thickness |

4OZ |

|

Layer |

Flexible PCB: 1-40 Layers |

|

Surface Finish |

HASL,Immersion Gold,Immersion Tin,OSP,ENIG+OSP,Immersion Silver,ENEPIG,Gold Finger |

|

Min. Hole Size |

Mechanical drill: 8mil(0.2mm) Laser drill: 3mil(0.075mm) |

|

Max. Panel Size |

1150mm × 560mm |

|

Our service |

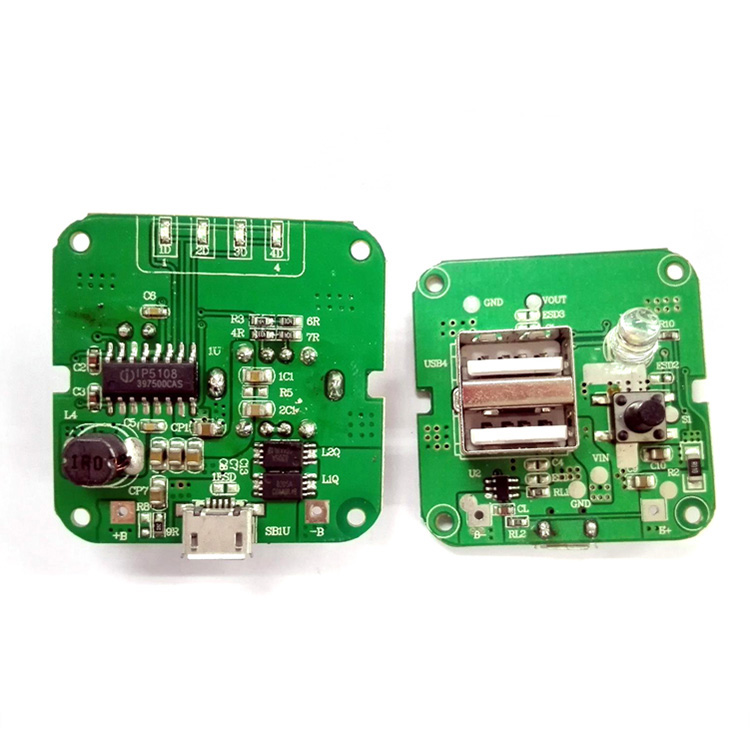

PCB making, PCB assembly, include testing & install plastic enclosure and component sourcing |

|

Certificate |

RoHS/ISO9001/TS16949/ISO14001/ISO13485 |

|

Testing |

In-Circuit test (ICT) Functional test Flying probe X-Ray Inspection Automated Optical Inspection (AOI) Custom designed and manufactured test systems |

Why Choose Us

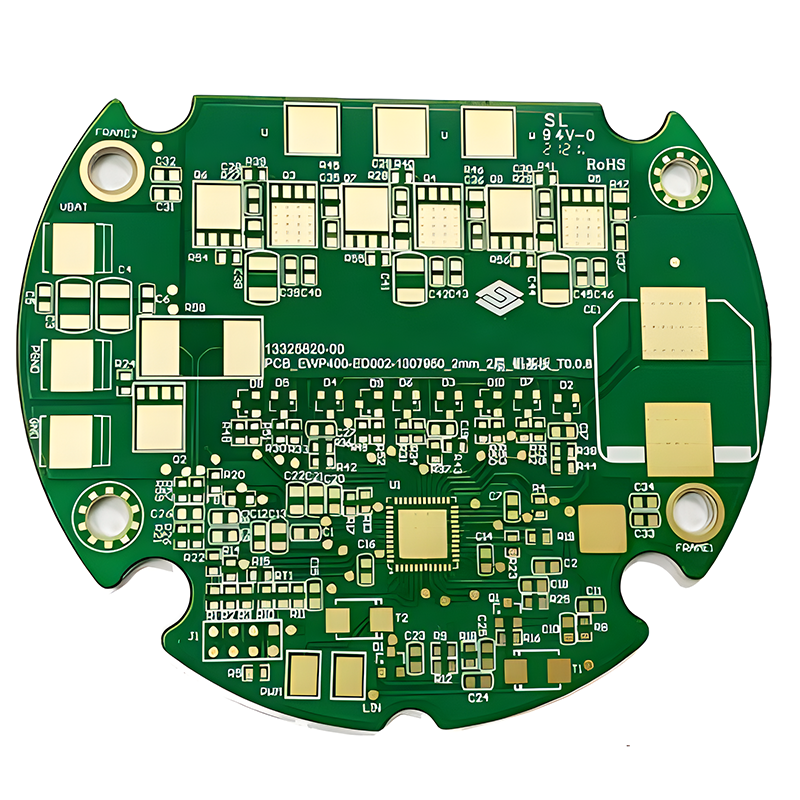

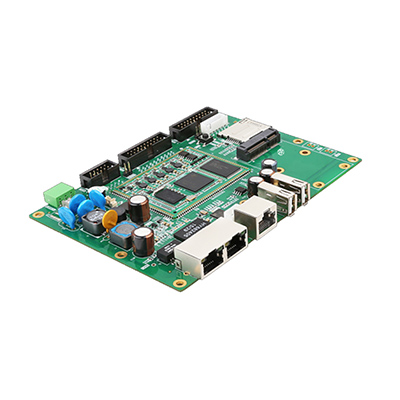

An automotive PCB used in cars or trucks, subassembly or dealer support system must be highly reliable and long-lasting under extreme temperature, dirt, chemicals, and moisture, and also important be highly competitive in price. Venture meets these criteria by providing automotive PCBs specifically designed to withstand the harsh conditions, we offer high-temperature laminates and copper & aluminum substrates, as well as differential copper, plated PCBs that are leading in the industry.

Application

Musatr specialises in providing electronic manufacturing services to the automotive industry with a strong focus on quality and reliability. We have extensive project experience and expertise, especially in the automotive industry. We provide our customers with highly reliable and cost-effective PCB assembly manufacturing services.

In order to meet our customers’ automotive PCB assembly manufacturing requirements, Musatr must ensure that their products are of high quality, reliability and safety. To achieve this, a number of quality control measures such as ISO 9001:2015, ISO 14001:2015 and IATF 16949 quality system standards are required to ensure that the products meet the standards of safety, reliability and performance requirements. In addition, PCB assembly manufacturers must also comply with stringent environmental regulations to ensure that the impact on the environment is minimised during the production of their products.

Musatr is able to provide our customers with a high quality, reliable and safety-compliant automotive electronics manufacturing service provider through quality control measures and environmental protection. We continually optimise our manufacturing service processes to ensure that our products consistently meet the highest standards of quality, reliability and environmental performance.

Musatr provides DFM reports prior to prototyping, which can help customers avoid glaring errors and reduce NPI time.

We can also help customers design functional test equipment to ensure product quality.

Musatr can provide test reports on solder reliability, soldering process and product reliability.

Write your message here and send it to us