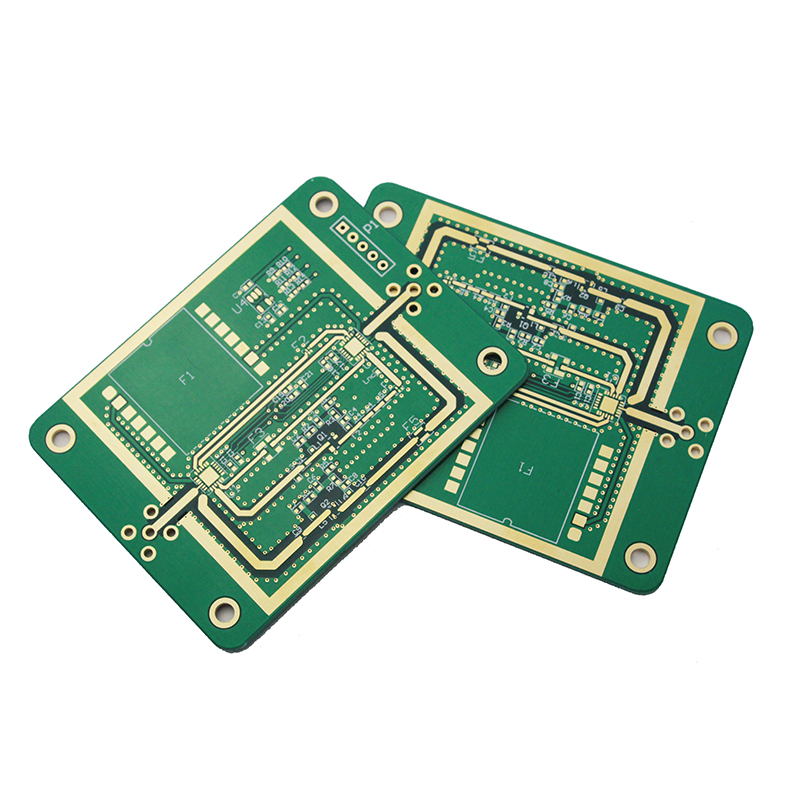

China Electronic High-Frequency PCB Supplier

Product Description

- High frequency PCB transmit electromagnetic waves with minimal losses. This type of PCB is commonly utilized in applications where transmission of signals between objects is required. In the fabrication of a high frequency PCB, the use of specific materials is required. This board features faster rates of signal flow. Its frequency range is about 100 GHZ. High frequency boards offer low levels of thermal expansion, lower DF, and lower DK. These circuit boards are commonly used for HDI technology.

Parameter

| Parameter | Capability |

| Material | FR-4 |

| Layer Counts | 1-64 layers |

| Board Thickness | 0.4mm-17.5mm |

| Board Outline Tolerance | ±0.15mm |

| Thickness Tolerance ( t≥0.8mm) | ± 8% |

| Minimum laser hole | 0.075mm (3mil) |

| Minimum Trace Width | 0.075mm (3mil) |

| Mini Solder Mask Bridge | 0.05mm |

| Minimum Drill Size | 0.15 mm (6 mil) |

| Maximum Board Size | 1150mm × 560mm |

| Surface Finish | HASL,Immersion Gold,Immersion Tin,OSP,ENIG+OSP,Immersion Silver,ENEPIG,Gold Finger |

| Testing Methods | In-Circuit Test (ICT), Flying probe test, Visual Inspection |

| Quality Standards | IPC-A-600F and MIL-STD-105D CHINA GB<4588> |

| Acceptable File Format | ALL Gerber Files、POWERPCB、PROTEL、PADS2000、CAD、AUTOCAD、ORCAD、P-CAD、CAM-350、CAM2000 etc. |

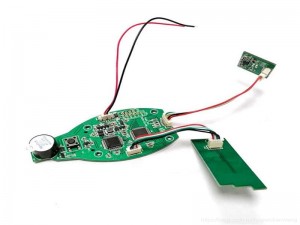

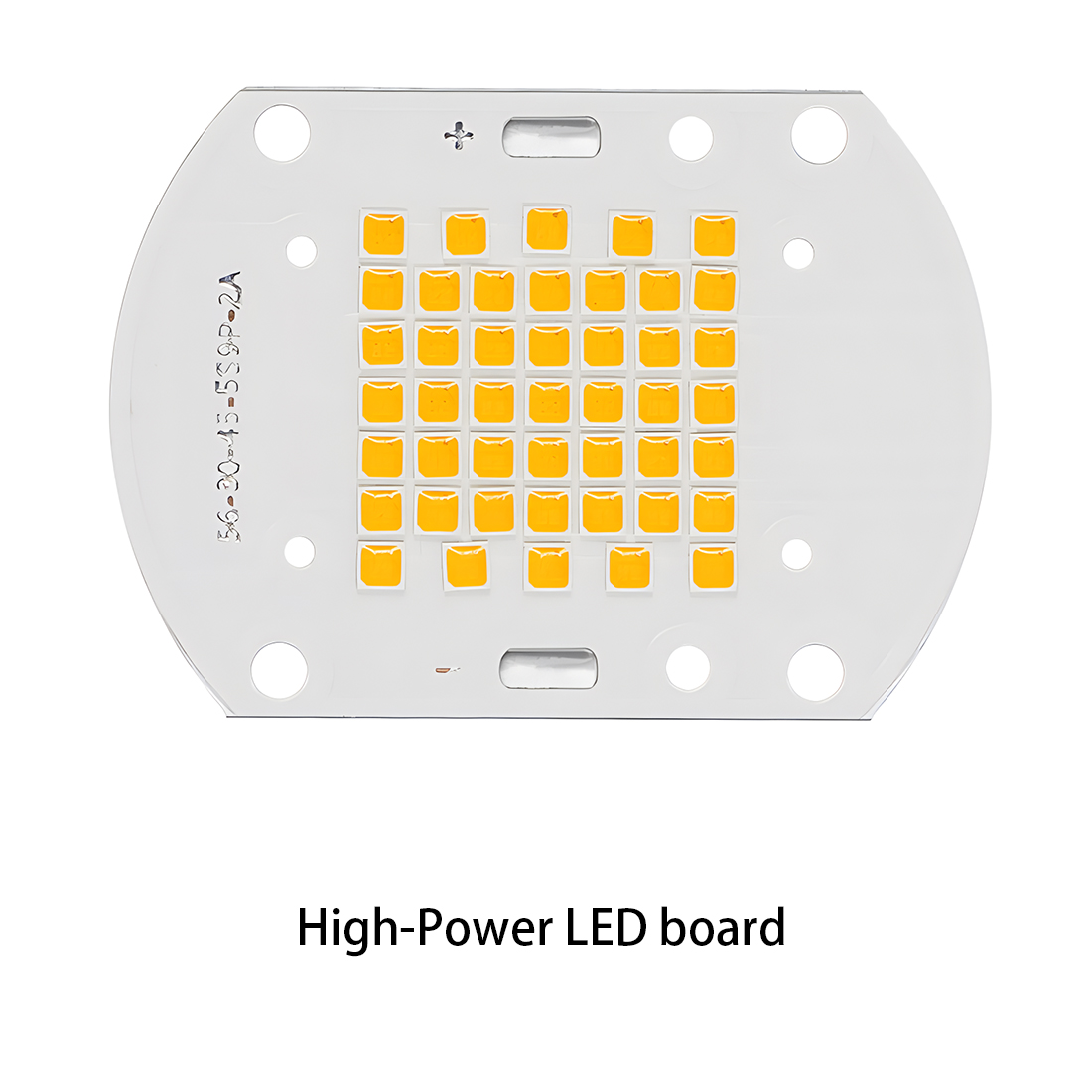

Applications For HF PCBs

High frequency rigid and flex PCBs are used in many products and across many industries, including:

Cell phone

Telecommunications

Military and aerospace

RF microwave

Automotive (mainly LIDAR, which is a mini radar that communicates a vehicle’s surroundings)

High-density interconnect and high-speed design applications

Materials Used for HF PCBs

Special materials are required to achieve the high frequency provided by this type of PCB. There are a variety of substrate materials that will support your design and may differ based on signal speeds required and the application/environment of the circuit board.

In terms of price, FR4 is the least expensive compared to dedicated high speed materials and Teflon, with Teflon being the most expensive. Though, FR-4 starts to drop off in performance when signal speed edges above 1.6ghz.

Newer generation substrates, Teflon, and flex circuits are the best options when it comes to Dk, Df, water absorption, and survivability in the environment.

If a printed circuit board requires a frequency above 10GHz, newer generation substrates, Teflon, and Flex substrates are your best option since they are far superior to traditional FR-4 material.

The most common suppliers of high speed substrates are Rogers, Isola, Taconic, Dupont, and Megtron materials by Panasonic. All of these materials typically are lower Dk and lower loss.

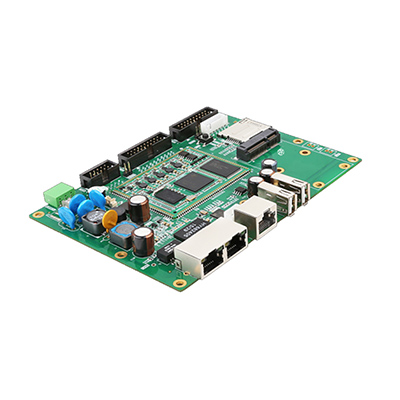

Cirexx’s HF PCB Capabilities

When it comes to high frequency PCB design, it’s important that the design engineer collaborate with the PCB supplier to select the materials for the desired frequency performance requirements and to establish the correct stack-up. Cirexx has deep engineering capabilities and experience with control depth drilling, control depth milling, and back drilling, unlike some of our competitors. This means we have the technology, the experience, and the knowledge to help you design and build the right high frequency PCB from the start.

We differentiate ourselves by being able to take on all complex jobs — all the way from layout through assembly — and we do this under one roof with state-of-the-art technology and an extensive engineering team. This end-to-end expertise allows us to excel at the entire process and be the best PCB provider in the country.

Write your message here and send it to us