China Slurry pump rubber liner factory and suppliers

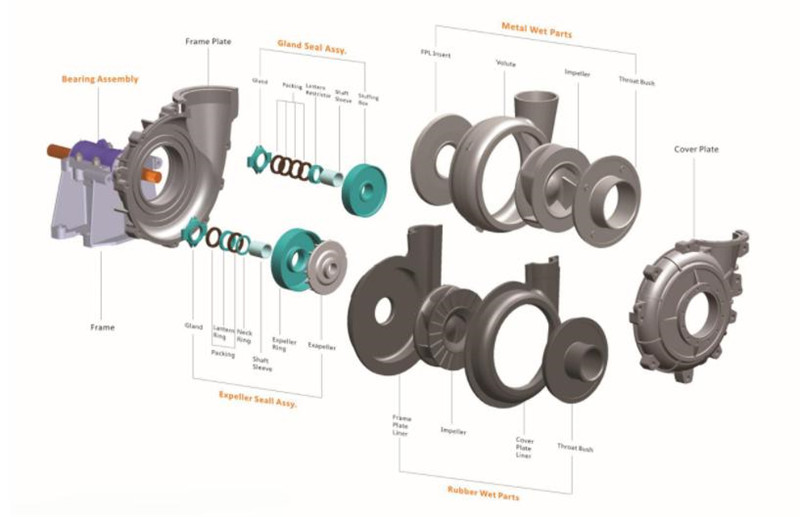

The rubber wet parts are great wear resistance and corrosion resistance, usually used for acid working conditions. Such as tailing in mining industry, slurry with small particles and no rough edges. The whole displacement part includes Cover Plate Liner, Throat bushing, Frame plate liner, Frame Plate Liner Insert.

The rubber material we used has superior resistance to all other materials in fine particle slurry applications. The antioxidants and anti degradents used in our material have been optimized to improve storage life and reduce degradation during use. The high erosion resistance is provided by the combination of its high resilience, high tensile strength and low shore hardness.

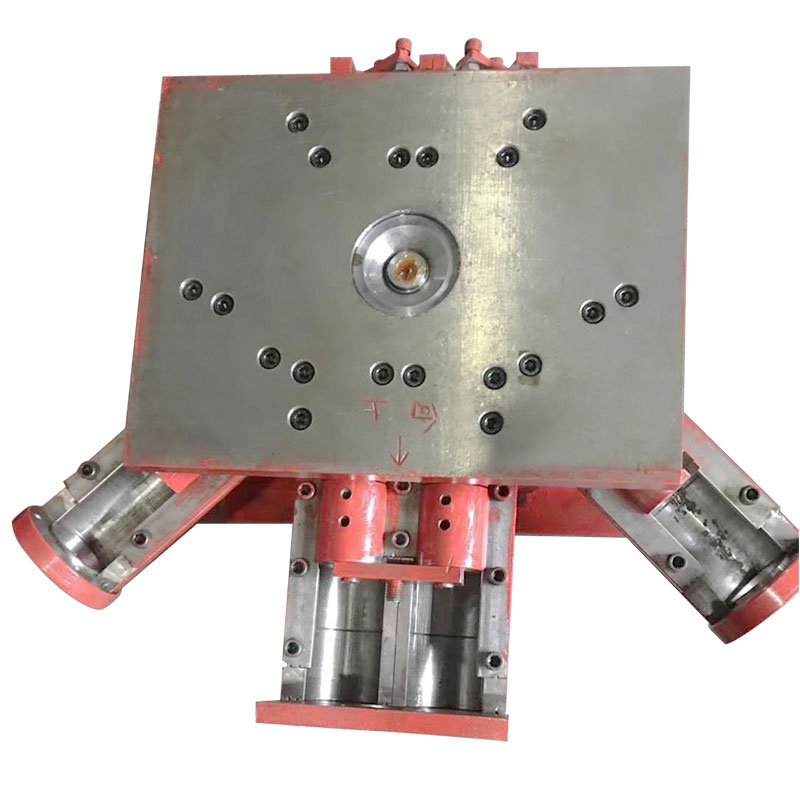

Rubber Pump Liners – Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

STRUCTURE OF SLURRY PUMP

*Because we are a real manufacturer, we have a lot of spare parts stock for slurry pump throat bush

RUBBER MATERIALS TYPE AND DATA DESCRIPTIONS

| Code | Material name | Type | Description |

| YR26 |

Anti Thermal Breakdown Rubber

|

Natural Rubber | YR26 is a black, soft natural rubber. It has superior erosion resistance to all other materials in fine particle slurry applications. The antioxidants and antidegradents used in RU26 have been optimized to improve storage life and reduce degradation during use. The high erosion resistance of RU26 is provided by the combination of its high resilience, high tensile strength and low Shore hardness. |

| YR33 |

Natural Rubber (Soft)

|

Natural Rubber | YR33 is a premium grade black natural rubber of low hardness and is used for cyclone and pump liners and impellers where its superior physical properties give increased cut resistance to hard, sharp slurries. |

| YR55 |

Anti Thermal Natural Rubber

|

Natural Rubber | YR55 is a black, Anti-corrosive natural rubber. It has superior erosion resistance to all other materials in fine particle slurry applications. |

| YS01 | EPDM Rubber | Synthetic Elastomer | |

| YS12 | Nitrile Rubber | Synthetic Elastomer | Elastomer YS12 is a synthetic rubber which is generally used in applications involving fats, oils and waxes. S12 has moderate erosion resistance. |

| YS31 |

Chlorosulfonated Polyethylene (Hypalon)

|

Synthetic Elastomer | YS31 is an oxidation and heat resistant elastomer. It has a good balance of chemical resistance to both acids and hydrocarbons. |

| YS42 | Polychloroprene (Neoprene) | Synthetic Elastomer | Polychloroprene (Neoprene) is a high strength synthetic elastomer with dynamic properties only slightly inferior to natural rubber. It is less effected by temperature than natural rubber, and has excellent weathering and ozone resistance. It also exhibits excellent oil resistance. |

SLURRY PUMP RUBBER PARTS APPLICATIONS

Slurry Pump Rubber Parts are widely used for AHR/LR/ Horizontal slurry pumps, SPR Vertical rubber lined slurry pumps, Centrifugal horizontal slurry pumps, Warman rubber lined slurry pumps, Chemical slurry pumps, Silica sand slurry pumps, Minerals processing slurry pumps, De-Watering Screen Pump, Ore sand pumps, Tailings Pump, Pipe-jacking slurry pumps, Ball mill discharge Pump, Tunnelling slurry pumps, Mixing tank slurry Pump, Wet crushers slurry pumps, SAG mill discharge pumps, Ball mill discharge pumps, Rod mill discharge slurry pumps, Ni acid slurry pumps, Coarse sand pumps, Coarse tailings pumps, Phosphate matrix slurry pumps, Scrubber slurry Pump, Minerals concentrate pumps, Heavy media slurry pumps, Dredging Sand slurry pumps, Bottom ash slurry pumps, Fly ash pumps, Lime grinding pumps, Screen feed Pump, Oil sands pumps, Mineral Sands pumps, Fine tailings pumps, Tailings booster Pump, Thickner Tailings Pump, Process recycle Pump, Pipeline transfer pumps, Phosphoric acid slurry pumps, Coal slurry pumps, Flotation pumps.

Disclaimer: is a registered trademark, and doesn’t represent or is not in anyway affiated with Warman®, and other brand names, all these brand names re respected of their owners. Any names, models, numbers, symbols or any descriptions are used for reference purpose only, and do not imply that any part or pump listed is the product of Warman®, spare parts only interchangeable. This document is the property of , and can be neither reproducted or disclosed to a third party withour a written authorization.