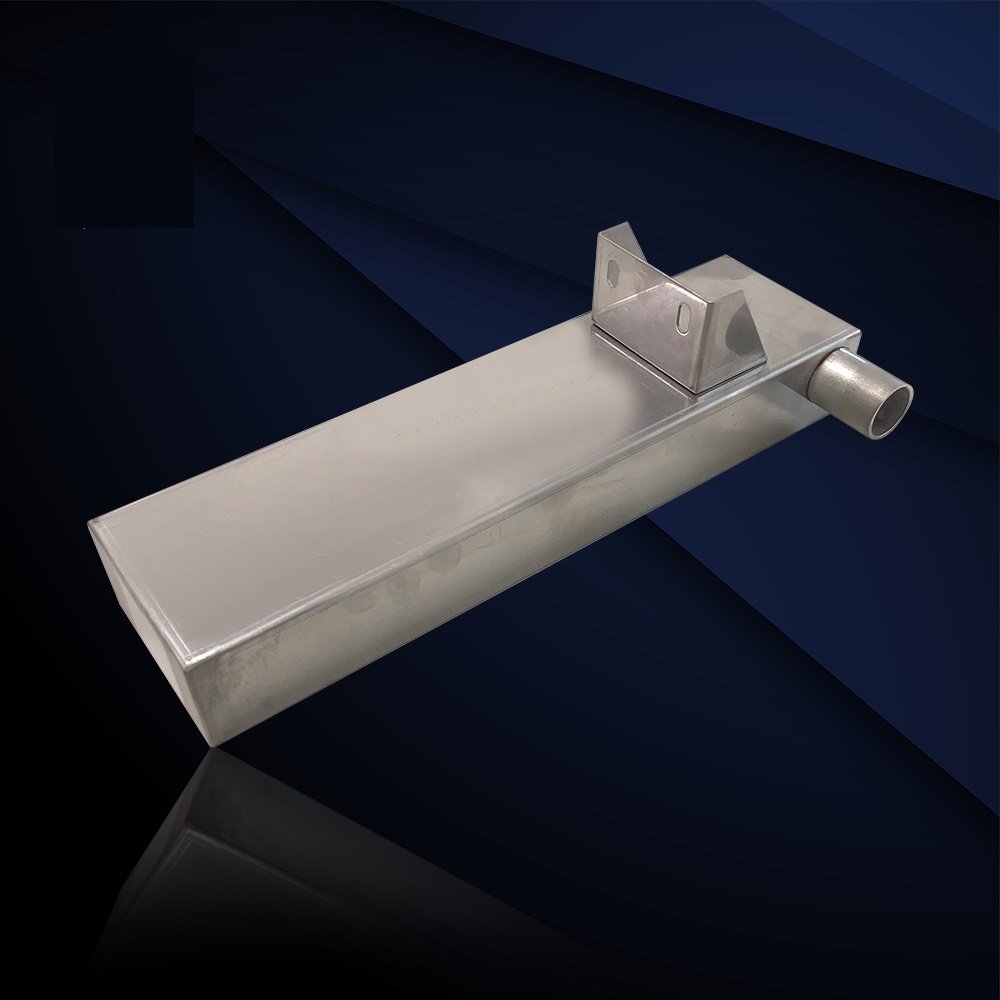

CNC maching Stainless Steel Flange

Product Description

Processing equipment cnc milling machine / CNC lathe / grinding machine / milling machine / lathe / wire cutting etc.

Customizable material Aluminum alloy:

5052/6061/6063/6065/2017/7075 etc.

Brass Alloy:

3602/2604/H59/H62 etc.

Stainless Steel Alloys:

303/304/316/412/440C etc.

Carbon Steel Alloys:

Carbon steel/die steel, etc.

Customizable material Aluminum alloy:

5052/6061/6063/6065/2017/7075 etc.

Brass Alloy:

3602/2604/H59/H62 etc.

Stainless Steel Alloys:

303/304/316/412/440C etc.

Carbon Steel Alloys:

Carbon steel/die steel, etc.

We handle many other types of materials. If you need materials not listed above, please contact us.

Surface Treatment Blackened, Polished, Anodized, Chrome-plated, Zinc-plated, Nickel-plated, Tinted

Inspection Height gauge, tooth gauge, video measuring instrument, three-dimensional measuring instrument, etc.

File formats AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, Solidworks, etc.

Special characteristics of CNC machining:

1. Custom tool steel parts typically have greater strength and integrity, as well as higher accuracy.

2. Custom machined parts can be manufactured much faster with CNC machines than many other methods.

3. Because CNC machining custom services maximize part detail, CNC machining custom is often manufactured for performance-critical industries.

4. Custom parts are non-standard or not available from common suppliers, and some features of custom parts are not available on standard components.

5. Mechanical CNC machining shops usually accept small quantities, and custom parts are usually produced for a specific end use and can be guaranteed to be produced and delivered within the agreed upon time frame and quality requirements.

Not only can we get your product right, but we are also located in the Greater Bay Area in southern China.

Our proximity to major shipping ports allows us to get your products to you quickly.

Frequently Asked Questions:

1. How long and how can I get a quote from your company?

We will reply to you within two hours once we get the details within a business day.

In order to give you a quote as soon as possible, please provide the following information along with your inquiry.

1). Detailed drawings (CAD/PDF/DWG/IGS/STEP/JPG)

2). Materials required

3). Surface treatment

4). Quantity (per order/per month/per year)

5). Any special requirements such as packaging, labeling, delivery, etc.

2.What should we do if we don’t have drawings?

Please send your samples to our factory, then we can do reverse engineering or offer you a better solution. Please send us pictures or sketches of the dimensions (length, height, width), and we will make CAD or 3D files for you if you place an order.

3. How do you control the quality?

(1)Material inspection-check the surface and approximate dimensions of the material.

(2) Production first inspection – Ensure critical dimensions in mass production.

(3) Sampling inspection-checking quality before sending to warehouse.

(4)Pre-shipment inspection- 100% inspection by QC assistant before shipment.

4. What will you do if we receive poor quality parts?

Please send us the pictures and our engineers will find a solution and re-create it as soon as possible.

5. If you need urgent delivery, can you help?

Of course! You need to tell us the delivery time when you place the order and we will do our best to adjust the production schedule.

6. Can you provide samples?

We can provide free samples for small existing parts, but for large and high value products, samples will be charged.

7.How about transportation?

You can choose any shipping method you need, sea, air or express.

8. How about the delivery time?

Usually 1–2 weeks for samples and 3–4 weeks for mass production.

9. What are the payment terms?

For new customers, we are more willing to use wire transfer in advance. For older customers, we can accept L/C and payment for delivery.

What’s Included in an Online Quote

1. Upload your CAD file

The first step is to simply fill in your information and upload your CAD file. This helps us create a 3D model of the desired part or prototype.

2. Quotation and design analysis

Within 12 hours, we will give you with a quote and DFM feedback. This ensures that your project can be done and gives you a correct cost estimate.

3. Order and start production

Once you have approved your quote and design, we will begin production of your CNC prototype or CNC machined part product.

4. Ship and get your parts

CNC machined parts or products will be produced within days. We ship to you by international express. Please feel free to give us feedback to make sure they meet your expectations.

High-quality precision machining requires more ability and detailed adherence to specific blueprints to create phenomenal products. When looking for great results, working with a reliable precision machining company is critical. We offer a wide range of precision machining services including precision turning, milling and EDM to meet your quality requirements.

What is your delivery time?

In fact, according to the delivery time required by customers.We will schedule production according to the current workload. Once your buy order is received, documentation is complete, and materials are ready, we will give prompt feedback on the exact delivery time, which typically ranges from 3 business days to several weeks, depending on the complexity of the part and quantity of parts ordered.

FQA

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.