CNC MACHINING

What is CNC Machining?

CNC machining, short for ‘Computer Numerical Control Machining’, is a one of the processing methods that machines the parts with the assistance of programmed tools. During the process, the programmed commands will control the toolings, and complete a series of operations to process the workpiece, until the end of the whole command. The operations include turning, milling, grinding, etc.

By manufacturing in the order of computer program, CNC machining is well-known for making high precision parts with higher accuracy, efficiency and lower cost than traditional manual machining. It has become one of the most effective ways to solve the problems of variable parts, whether in small batch manufacturing, or making high precision complex shaped parts, to achieve high-efficiency and automated processing.

Features and advantages of CNC Machining

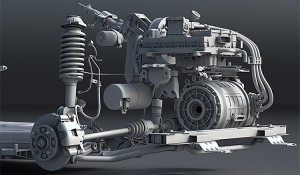

One of the major features of CNC machining is its auto manufacturing. With programmed control to move the tooling and adjust the workpiece, it takes much less time to complete machining process. Besides the high efficiency, designing and adjusting the process through the computer software further ensures the parts’ high quality, fine details and tight tolerance, however complex the component can be.

Because of the whole process being operated inside a closed CNC machine, it enables the safety for engineers to inspect and adjust during the working process. With a wide choice of tooling, CNC machining is also capable of making parts from a large range of material, including aluminum, stainless steel, zinc, and even non-metallic material like POM.

With such features and advantages above, CNC machining is one of the best manufacturing solutions for parts that have unique or complex strcutres, or specific requirement in standard or tolerance.

Application of CNC Machined Parts

CNC machined parts are widely used in many sections of applications:

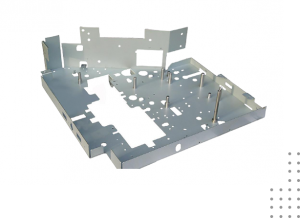

Machinical industry - customized gears, fixtures, shafts, molds, etc.

Aerospace - frames, supporting parts, turbine blades, etc.

Electronics - connectors, circuit boards, enclosures, etc.

Automotive - engine parts, system components, housings, etc.

Medical - measure device parts, surgical tools, implants, etc.

…and many others.

Along with the application, requirements for more precise and complex shaped parts are also increasing, further being a long-term test for CNC machining.

Need a help with CNC Machining Service?

QY Precision has dozens of CNC machines, with teams of experienced engnieers and programmers who are experted in mechanical design and CNC machining.

With years of successful experience making different kinds of high precision parts for worldwide customers, we have condifence and strict inspection for our quality and the required standards.

If you have trouble for making your parts, QY Precision is always ready for service.

Welcome to QY Precision, and kindly contact us with your inquiry.