CNC Milling Services–Engaged In The Custom Processing

CNC milling machine is an automatic processing equipment developed on the basis of ordinary milling machine. In addition to the processing characteristics of ordinary milling machines, the milling machine controlled by the digital signal of the electronic watch also has the following characteristics

1. Parts processing not only has strong adaptability and flexibility, but also can process parts with particularly complex contour shapes or difficult-to-control sizes;

2. It can process parts that cannot be processed or difficult to process by ordinary machine tools, such as complex curve parts described by mathematical models, three-dimensional space surface parts, etc.;

3. It can better avoid manual operation errors, and can stably process high-precision, high-quality parts

4. The high degree of production automation can reduce the labor intensity of operators and is conducive to the automation of production management;

5. High production efficiency. The CNC milling machine only needs to call the processing program stored in the CNC device, install the tool and adjust the tool data, which greatly shortens the production cycle. Secondly, the CNC milling machine has the functions of milling, boring, and drilling, which makes the process highly concentrated and greatly improves production efficiency.

Business development source customer trust and support

K-TEK has earned a reputation and satisfaction from customers for its high-quality machined parts, innovative technology, versatile manufacturing capabilities, and favorable prices. 70% of the company’s customers are located in Europe, the United States, and Japan. At the same time, they also hope to seek longer-term support and cooperation with global customers.

Distribution of major customers

K-TEK has 70% of customers from Europe, America and Japan., etc and is still expanding the global market, looking for long-term and stable customers.

Application field and processing capacity

K-TEK has rich experiences in machining parts for various industrials such as electronics, equipment, medical equipment, automation equipment and jig & fixture.,etc, can realize customized production of multiple varieties and small batch orders according to customer needs. In addition to our sophisticated CNC processing equipment, we also have a large number of auxiliary processing equipment, which can complete the integrated parts production of various processes. Here is our equipment list :

| Equipments List | |||||

| Processing equipment | Name | Brand | Typ | Process Range | Qty. |

| Five-axis Machining Center | DMG MORI | DMU75 | 700*500 | 2 | |

| CNC Milling Machine | BRIDGEPORT、 Brother | GX800、FVP-800A | 1300*700mm | 26 | |

| CNC Lathe | Saintes | M08SY-11 | 0-320 mm | 7 | |

| WEDM-LS | Sodick | AQ400Ls | 400*300*250 | 2 | |

| WEDM-HS | Quartet Xiongfeng | DK7732 | 350*400mm | 14 | |

| Miller | Taiwan | FTM-X4 | 1100*400 | 12 | |

| Lathe | Jingzhou Hehua | C6140E-3 | 432-1000mm | 7 | |

| Grinder | KENT | HF-618S | 150*800 | 8 | |

| Internal/External Grinder | Beijing/Shanaghai | M1432B | 1000*320 | 2 | |

| Mirror EDM | Toptech | AL435H | 500*400 | 3 | |

| Puncher | Qiaofeng | HF-2030A | 300*200mm | 1 | |

| Drill machine | Zhejinag Xiling | ZQ4113 | 0-13mm | 2 | |

| Inspection equipment | 3D CMM | Zeiss | ZEISS | 1000*700mm | 1 |

| 2D CMM | Jiateng | VMS-3020 | 300*200mm | 5 | |

| Height Gauge | Trimos Tesa | TESA700 | 0-800mm | 6 | |

| Hardness tester | Dechuan instrument | HR-150A | - | 3 | |

| Material Analyzer | Niton | XL2 980 | |||

| Glossmeter | Mitutoyo | SJ-210 | - | ||

| Innternal Micrometer | Mitutoyo | 293-821-30 | 0-200 | ||

| 3 Points Internal Micrometer | Mitutoyo | 486-163、164 | 0-150 | ||

| Others: Outside / Internal Micrometer, Callipers, Ring Gage, Thread Gauge, Pin Gage, Block Gauge, Dial Gauge. | |||||

Machining Commonly Used Materials & Surface Treatment

K-TEK can not only process parts made of various materials such as steel processing, aluminum processing, stainless steel processing, copper processing, plastic processing, etc., but also process different types of surface treatments such as anodizing, black oxide, sandblasting, and painting.,etc. K-TEK also has systematic testing requirements, Incoming material test, production test and shipment test to ensure our products with good quality .Common materials and surface treatment are as follows:

|

Common materials & Surface treatment |

||

|

Common Materials |

Steel |

20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, etc. | ||

|

Aluminum |

LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, etc. | ||

|

Stainless Steel |

SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, , SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, etc. | ||

|

Copper |

T2, TU1/2, TP1/2, , Brass, Copper, Bronze, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, etc. | ||

|

Plastic |

PEEK, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET+30%GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, etc. | ||

|

Surface treatment |

Clear Anodize, Black Anodize, Hardness Anodize, Blue/Red Anodize, Chromate Plating, QPQ | |

| Electroless Nickel/Nine/Chromium Plate, Black Oxide, Silver\Golden plating, Sanded, DLC | ||

| Orbital Sanded, Passivated, TIN PlatingTungsten Carbide Coating, Polyurethae coating, etc. | ||

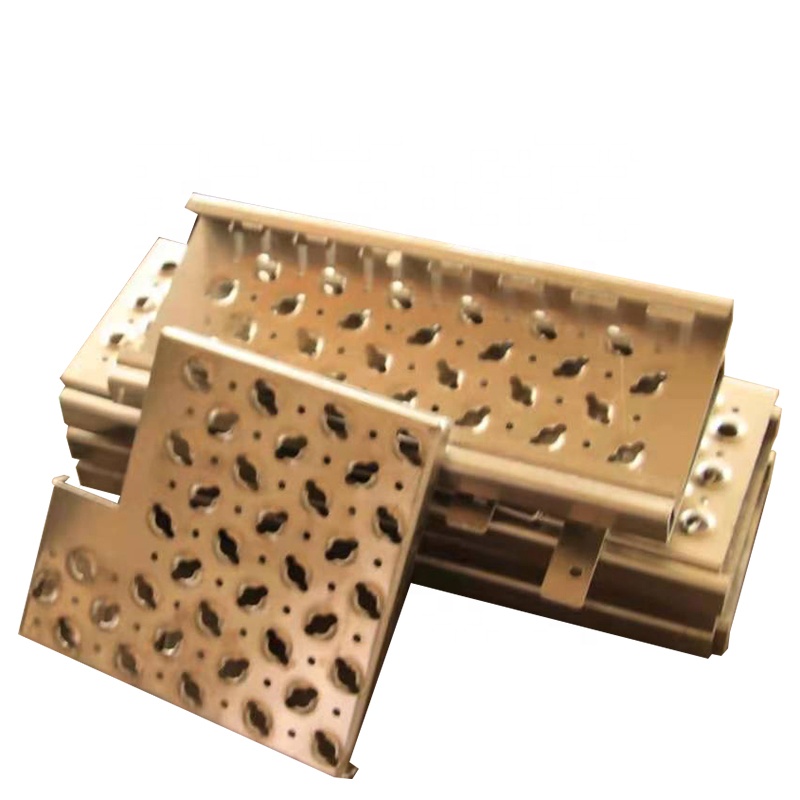

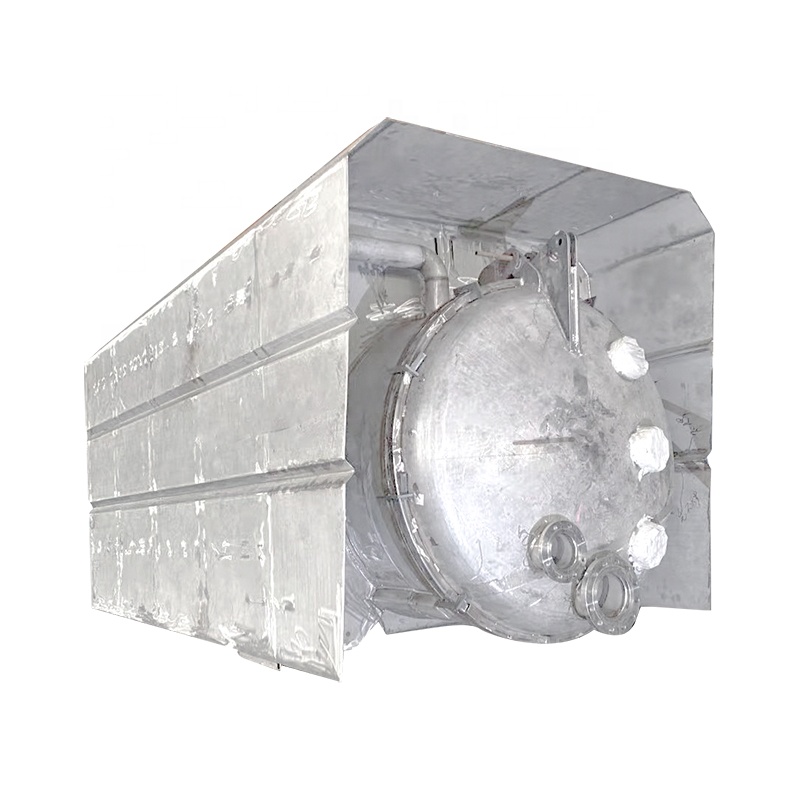

Samples

K-Tek is mainly engaged in the custom processing of multi-variety and small-batch mechanical parts, all parts are done according to the needs of customers.

Our processing services include:

1) 5 Axis CNC Machining /CNC Milling/CNC Turning;

2) Milling/Turning/ grinding;

3) Heat treatment /Surface treatment.

Here are some processing cases that we have produced before: