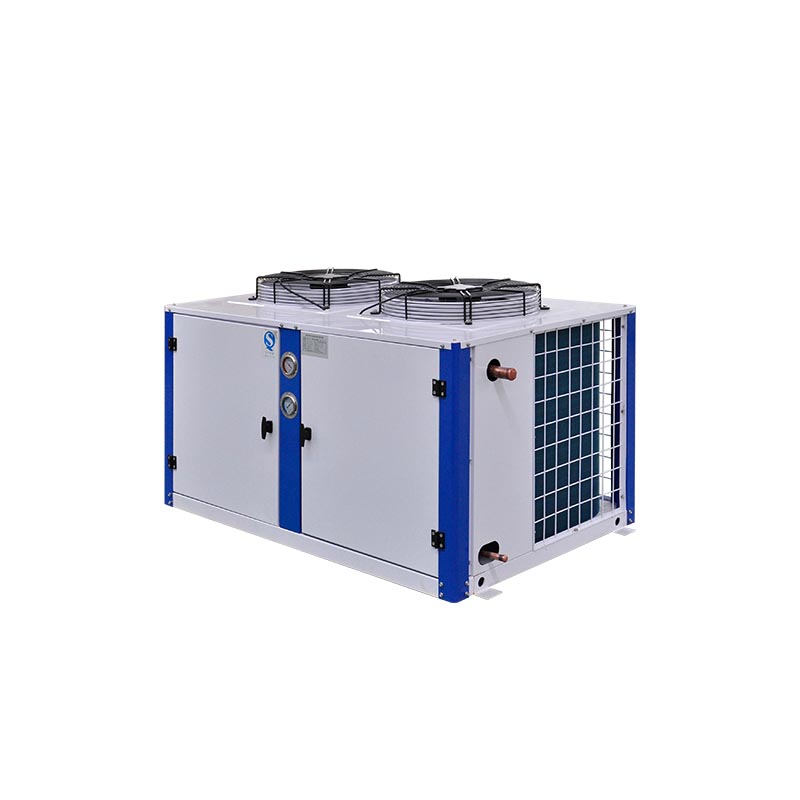

Cold Room Box U Type Condensing Unit

Condensing Unit Description

Condensing unit is including reciprocating, screw and scroll compressor unit, air cooled and water cooled condensing unit, CO2 compressor unit , monoblock unit etc. Condensing unit can be used in walk in chiller, walk in freezer, blast freezer, fast frozen tunnel, retail refrigeration, cold chain logistics, chemical and pharmarcy area, seafood and meats industry etc.

With professional refrigeration technology, special R&D development and strong ability, with advanced equipment and technology, we have complete production management, quality control, and after-sale service system for condensing unit.

Condensing unit is mainly assembled with semi-hermetic compressor. Compressor brand includes Emerson,Bitzer,Refcomp,Frascold and other brands.

1. Main components are compressor, condenser, drier filter, solenoid valve, pressure controller, high and low pressure gauge. Gas separator and oil separator are optional. Brand for all these spare parts is optional

2. Condensing unit is easy to moving, installation and maintenance.

3. Pressure controller are designed to protect the whole compressor system when the equipment breaks down or overloads.

4. Refrigerant: R22, R404A,R507a,R134a.

5. Power supply: 380V/50Hz/3phase, 220V/60Hz/3phase, 440V/60Hz/3 phase and other special voltage can be customized.

Features for Box U Type Condensing Unit

The shell is of box structure with secure connection,and the compressor horse power is from 1hp~30hp,which is suitable for both the hermetic and semi-hermetic compressors in various brands.

All the units are tested under 2.8Mpa gas tightness and pollution discharge,which is suitable for refrigerant R22, R134a, R404a R407c, R507a and so on.

FNU type condenser is of wide surface, with excellent performance in heat exchanging ,which is widely used for various condensing units

All the fans are axial fans, which is easy for installation and maintenance ,with stable operation and low noise.

Design Principle

For small and medium cold room, we usually choose semi-closed piston condensing unit. For large cold room, we usually choose parallel compressor unit. For blast freezer, we usually choose screw type compressor or double stage compressor. For the cooling capacity, we will design it to meet our clients’ requirement.

For some countries, in Winter the temperature is lower than minus 0°C or in Summer the temperature is more than 45°C. We will consider the climatic environment of the location, and chose suitable condenser model for customers.

For condensing unit installation, we will provide drawings and professional online guidance for reference.

How will we choose condensing unit of cold room?

The difference between cold room and refrigerator most lies in the applicability and complexity of equipment.

When selecting a compressor, it is necessary to choose a compressor that is durable, easy to use and low in operation and maintenance costs on the basis of meeting the requirements of refrigeration capacity. In general, small cold room uses fully enclosed compressors, because fully enclosed compressors have small power and relatively cheap price; Medium-sized cold room capacity is large, generally choose multi-cylinder semi-closed compressor.

When we design the cold room, we also will choose type of condensing unit suit for our customers, easy to install, or low noise, or high quality, or famous brand, etc, to meet different requirement.

Packing and Delivery