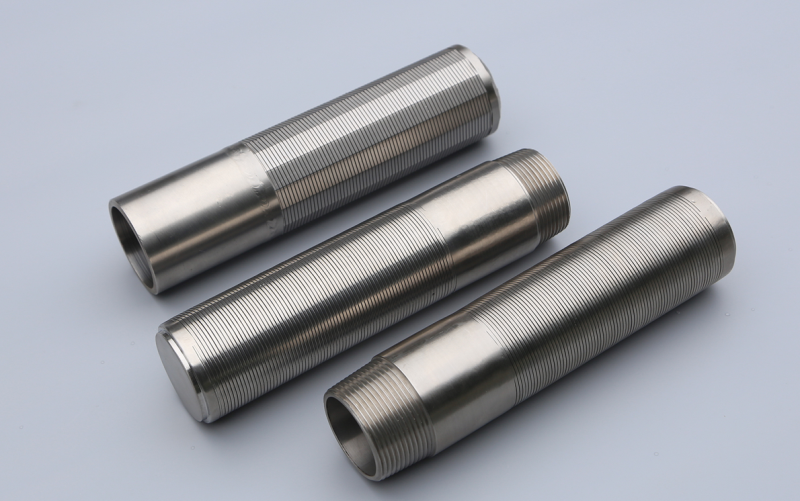

Copper Powder Sintered Filter Element

Product SpecificationsHuahang

|

Type |

Sintered powder filter element |

|

OD |

80 |

|

Height |

500 |

|

Material |

Copper powder |

|

Filtration accuracy |

0.1~50μm |

Product featuresHuahang

1. High filtration accuracy, stable pores, and no change in pore size with pressure. It can effectively remove suspended solids and particles, with excellent filtration accuracy and good purification effect.

2. Good breathability and low pressure loss. The filter element is completely composed of spherical powder, with high porosity, uniform and smooth pore size, low initial resistance, easy backflushing, strong regeneration ability, and long service life.

3. High mechanical strength, good rigidity, good plasticity, oxidation resistance, corrosion resistance, no need for external skeleton support protection, simple installation and use, convenient maintenance, good assembly performance, and can be used for welding, bonding, and mechanical processing.

4. Uniform pores, especially suitable for situations with high uniformity requirements such as fluid distribution and homogenization treatment.

5. Copper powder sintered products are formed in one go without the need for cutting, with high effective utilization of raw materials and maximum material savings, especially suitable for components with large batches and complex structures.

Application AreaHuahang

1. Catalyst filtration;

2. Filter liquids and gases;

3. Recovery and filtration of mother liquor in PTA production;

4. Filtering in food and beverages;

5. Boiling vaporization bed;

6. Liquid flushing tank bubbles;

7. Fire and explosion resistance;

8. Balancing and damping airflow;

9. Probe protection of sensors;

10. Filtering and noise reduction on pneumatic equipment;

11. Fly ash treatment;

12. Gas homogenization and pneumatic conveying in the powder industry.

Write your message here and send it to us