Custom Online Injection Molding Service

Our Custom Injection Molding Services

Utilizing Precision injection molding solutions in China, we shape plastic parts based on part size, intricacy, and volume requirements. On-demand prototypes and production runs are made possible with machines ranging from 30t to 1800t, ensuring every design’s accuracy. Benefit from free design consulation on each injection molding order. Expect quick turnarounds with lead times as short as 15 days.

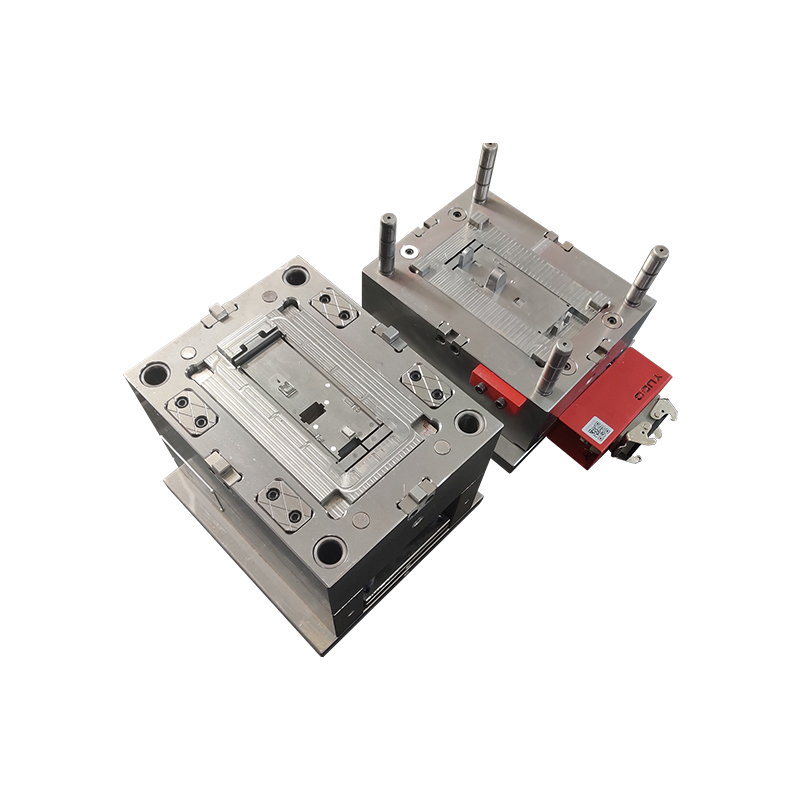

Injection Mold Tooling

Plastic Injection Molding

Overmolding

Insert Molding

Custom Injection Molding Solutions

Explore our on-demand injection molding solutions to seamlessly transition from prototyping to high-quality production.

Rapid Prototyping

Low Volume Production

Injection Molding Materials

Breton Precision offers common metals for injection molding tooling, and a variety of popular plastic materials

Injection Mold Tooling Materials

Thermoplastic

Thermoset

| Liquid Silicone Rubber | Epoxy |

| Polyurethane | Phenolic |

Injection Mold Surface Finishes

We primarily offers SPI finishes for plastic injection molds. For VDI textures, specify your requirements when submitting your quote on our platform.

| SPI Finish Standards | Surface Roughness RA (mm) | Finishing Method | Texture | Steels Recommended |

| SPI A1 | 0.012 to 0.025 | 6000 Grit Diamond | Super High Glossy finish | S136 (54HRC) or 8407(52HRC) |

| SPI A2 | 0.012 to 0.025 | 3000 Grit Diamond | High Glossy finish | S136 (54HRC) or 8407(52HRC) |

| SPI A3 | 0.05 to 0.10 | 1200 Grit Diamond | Normal Glossy finish | S136 (300HB) or 718H |

| SPI B1 | 0.05 to 0.10 | 600 Grit Paper | Fine Semi-glossy finish | 718H |

| SPI B2 | 0.10 to 0.15 | 400 Grit Paper | Medium Semi-glossy finish | 718H |

| SPI B3 | 0.28 to 0.32 | 320 Grit Paper | Normal Semi-glossy finish | 718H |

| SPI C1 | 0.35 to 0.40 | 600 Grit Stone | Fine Matte finish | 718H |

| SPI C2 | 0.45 to 0.55 | 400 Grit Stone | Medium Matte finish | 718H |

| SPI C3 | 0.63 to 0.70 | 320 Grit Stone | Normal Matte finish | 718H |

| SPI D1 | 0.80 to 1.00 | Dry Blast Glass Bead | Satin Textured finish | 718H |

| SPI D2 | 1.00 to 2.80 | Dry Blast | Dull Textured finish | 718H |

| SPI D3 | 3.20 to 18.0 | Dry Blast | Rough Textured finish | 718H |

Classes of Injection Mold

We adhere to the five standard categories of SPI mold classifications from Class 101 to 105, aligning expectations for customers and suppliers alike.

| Mold Class | Production Level | Cycles | Applications | Tolerance | Cost | Lead Time |

| Class 105 | Very low | Less than 500 cycles | Prototype testing | ± 0.02mm | Inexpensive to produce a very limited number of product prototypes | 7-10 days |

| Class 104 | Low | Less than 100K cycles | Good for limited-production parts with non-abrasive materials | ± 0.02mm | Fall within low to moderate price ranges | 10-15 days |

| Class 103 | Medium

|

Less than 500K cycles | For low to medium-production parts | ± 0.02mm | Fall within common price ranges | 10-15 days |

| Class 102 | Medium to high | Less than 1M | Good for parts with abrasive materials and/or tight tolerances | ± 0.02mm | Fairly high price and made with materials of high quality | 10-15 days |

| Class 101 | Extremely high | Over 1M cycles | Extremely high production and fast cycle times | ± 0.02mm | Highest price and made with only the highest quality materials | 10-18 days |