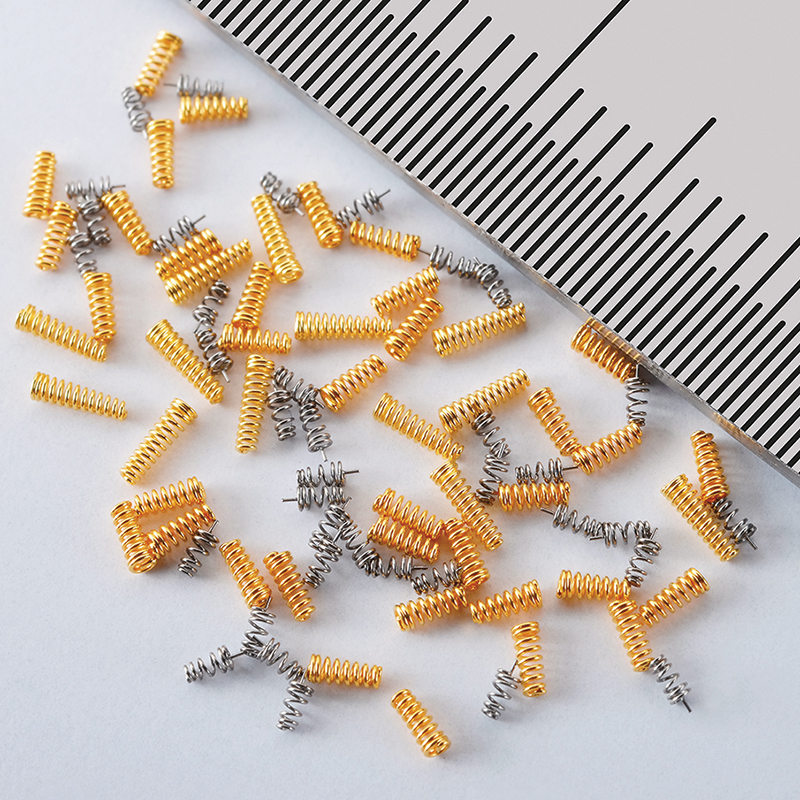

Custom precision compression springs with secondary machining

Compression springs Gallery:

Specifications Of Our Compression Springs

A compression springs manufacturer and designer must consider certain dimensions when producing products for varied uses. The wire, inner and outer diameter, spring rate, solid length and free length are some of the parameters that will matter. The ends are also essential when buying stainless steel compression springs.

We offer a variety of custom specifications so you can order the suitable compression spring for your specific needs. From different wire sizes, materials used and even finishes, you can ensure that you are receiving the best possible service and product from Springs.

|

Wire Size |

0.025mm (.005”) upwards. |

|

Material |

spring steel, stainless steel, music wire, silicon-chrome, high carbon, beryllium-copper, Inconel, Monel, Sandvik, galvanized wire, mild steel, Tin-plated wire, Oil-Tempered Spring Wire, phosphor bronze, brass, Titanium. |

|

Shapes |

helical, conical, barrel, hour-glass. |

|

Ends |

open, closed & ground, closed & unground. |

|

Finishes |

Various coatings include but not limited to Zinc, Nickle, Tin, Silver, Gold, Copper, Oxidization, Polish, Epoxy, Powder coating, dyeing and painting, Shot peening, plastic coating |

|

Quantities |

we can produce large quantities efficiently using modern computer-aided machines also we have the facility to make small quantities of prototypes and samples to specifications. |

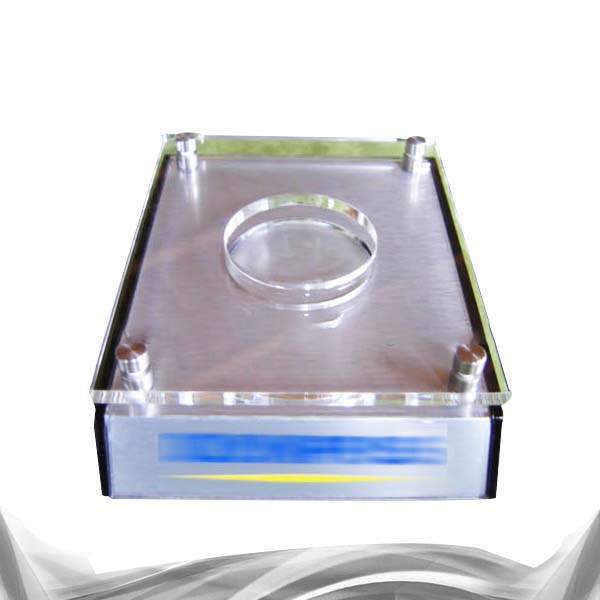

Tower type spring

Compression spring

What are compression springs?

Compression springs are the helical spring which can resist the force which applied axially. Their material’s cross section are mostly coiled with round, rectangular and multistranded wire. Usually there are many gaps(pitch) between each coil of compression springs. They are shrinked when there is push force applied, thus store the energy by this kind of deformation.

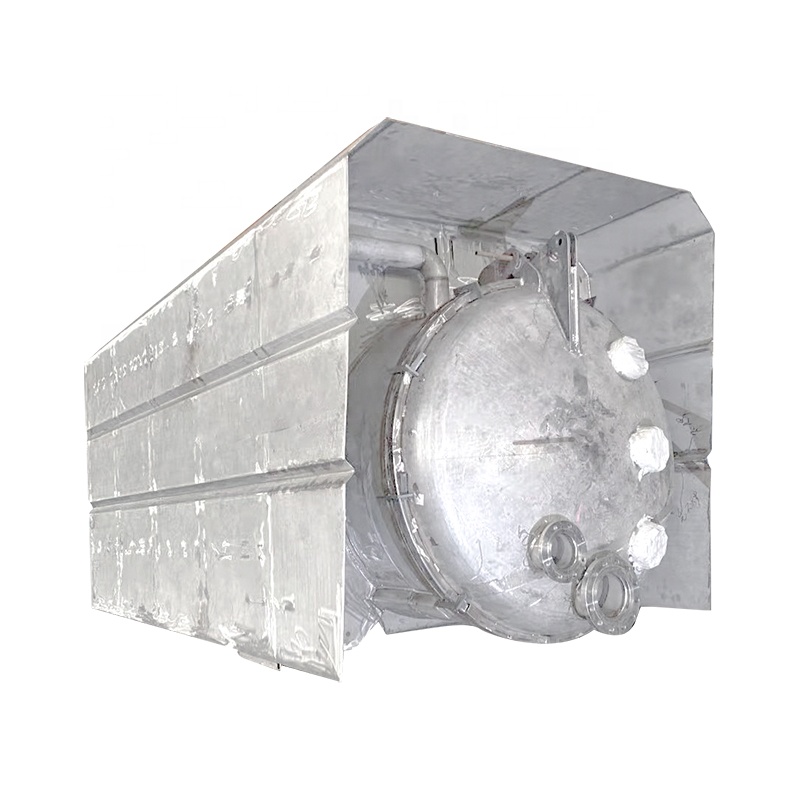

Trusted custom compression springs manufacturer

Custom Spring Manufacturing is an ISO 9001:2015-certified fabricator of metal springs for industrial applications. The ability to produce custom compression and helical springs that meet your performance requirements is what sets us apart.

Here’s what we are doing and what we can offer to save your time and money. :

▶ Spring Design

▶ Heat Treating

▶ Passivation

▶ Orbital Welding

▶ Tube Bending

▶ Shot-Peening

▶ Coating And Plating

▶ Non-Destructive Examination, or NDE

Common uses of compression springs

Compression springs are one of the most versatile springs and can, therefore, be used in many applications across all industries. Common uses include:

▶ Medical Devices

▶ Electronics

▶ Control Room Equipment

▶ Industrial Machinery

▶ Construction Equipment

▶ Automotive Parts

▶ Materials Handling Equipment

▶ Home applicance

▶ Outdoor goods

▶ Oil And Gas Tools

▶ Package Equipment

▶ Button-Operated Devices

▶ Precision Instruments And Tools