Custom steel extension springs with required different loops

Extension Springs Gallery:

Specifications Of Our Extension Springs

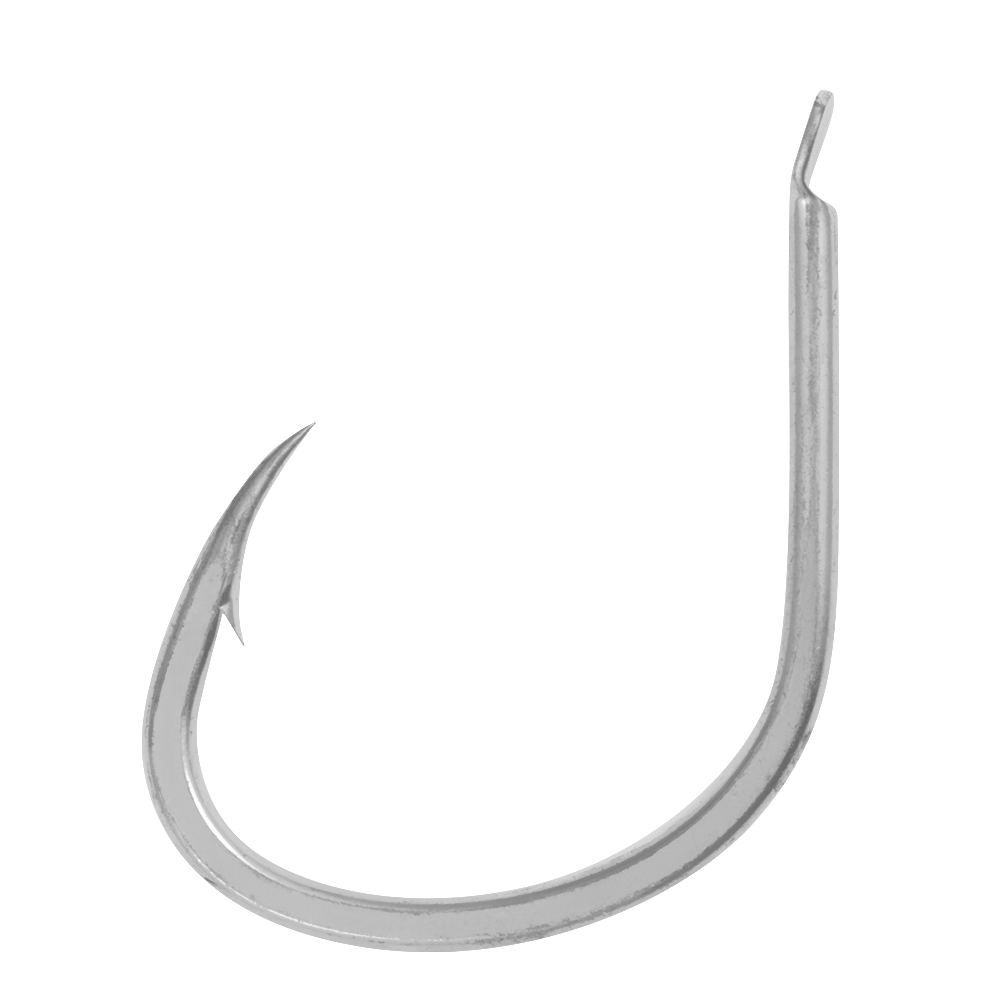

The initial tension applied dictates how close these coils are and by controlling this initial tension, it is possible to customise the spring to cater to specific load requirements. The coiled design of a spring is what provides the strength and elasticity. A tension spring is tightly wound and when in a rest state, it remains coiled. We include interfaces such as eyes, hooks or loops at both ends to facilitate attachment to other components.

We offer a variety of custom specifications so you can order the suitable extension spring for your specific needs. From different wire sizes, materials used and even finishes, you can ensure that you are receiving the best possible service and product from Springs.

| Wire Size | 0.1mm upwards. |

| Material | spring steel, stainless steel, music wire, silicon-chrome, high carbon, beryllium-copper, Inconel, Monel, Sandvik, galvanized wire, mild steel, Tin-plated wire, Oil-Tempered Spring Wire, phosphor bronze, brass, Titanium. |

| Ends | there is a wide variety of end types that can be put on a tension spring including machine loops, extended loops, double loops, tapers, threaded inserts, hooks or eyes at various positions and extended hooks. |

| Finishes | Various coatings include but not limited to Zinc, Nickle, Tin, Silver, Gold, Copper, Oxidization, Polish, Epoxy, Powder coating, dyeing and painting, Shot peening, plastic coating |

| Quantities | we can produce large quantities efficiently using modern computer-aided machines also we have the facility to make small quantities of prototypes and samples to specifications. |

What are extension springs?

Tension springs, or extension springs, are one of the most commonly known springs in the spring manufacturing industry. They are tightly wound coils that are designed to operate with tension force. Tension springs are helical coiled springs designed to bring components together, or for attachment purposes – using loops and hooks – rather than to keep them apart. A high-tension spring works by absorbing energy and storing it and when tension is applied, its energy creates a resistance to counter the pulling force.

Trusted custom extension springs manufacturer

Custom Spring Manufacturing is an ISO 9001:2015-certified fabricator of metal springs for industrial applications. We manufactured springs from circular, rectangular or square material which offers resistance to a force applied axially whose free length extends in the direction of an applied load.

The ability to produce custom extension springs that meet your performance requirements is what sets us apart.

Here’s what we are doing and what we can offer to save your time and money. :

▶ Spring Design

▶ Heat Treating

▶ Passivation

▶ Orbital Welding

▶ Tube Bending

▶ Shot-Peening

▶ Coating And Plating

▶ Non-Destructive Examination, or NDE

Common uses of extension springs

The design, size and flexibility of a tension spring mean it has lots of uses including:

▶ Trampolines

▶ Automotive interior and exterior

▶ Garage doors

▶ Farm equipment

▶ Pliers

▶ Vice-grip pliers

▶ Toys

▶ Washing and medical devices