Customized Workshop New Model Double Girder Overhead Crane for sale

QD electric double girder overhead crane

QD electric double girder overhead crane with hook is widely used hoisting machinery currently. The load handling device is the hook. The crane, of classfication group of A3-A57, has a commonly used lifting load of 3-250t, so that it is suitable ti work in factories, warehouses and freight yards where the ambient temperacture is -25℃~ +40℃ and the relative humidity is not more than 85%. It is prohibited ti work in the environment with inflammable, esplosive and corrosive gas.

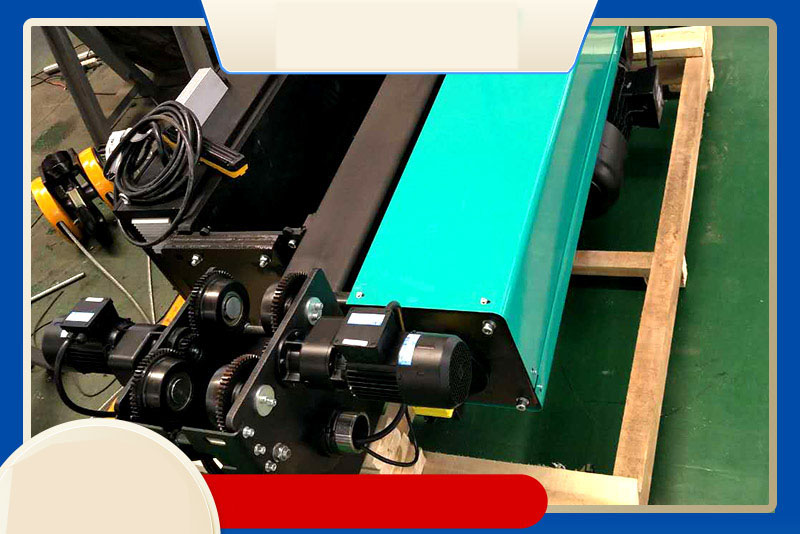

LH Model Electric Hoist Bridge Crane

LH model electric hoist bridge crane has such features as tight dimensions, low building headroom, light dead weight and light wheel load. They are applicable to the transfer, assembly, check and repar as well as load and unload at mechanic processing workshop, subsidiary workshop of metallurgical mills, warehouse, goods yard and power station, production workshop in light textiles or food industry.. It is forbidden to work in environment with combustible, explosive or corrosive media.