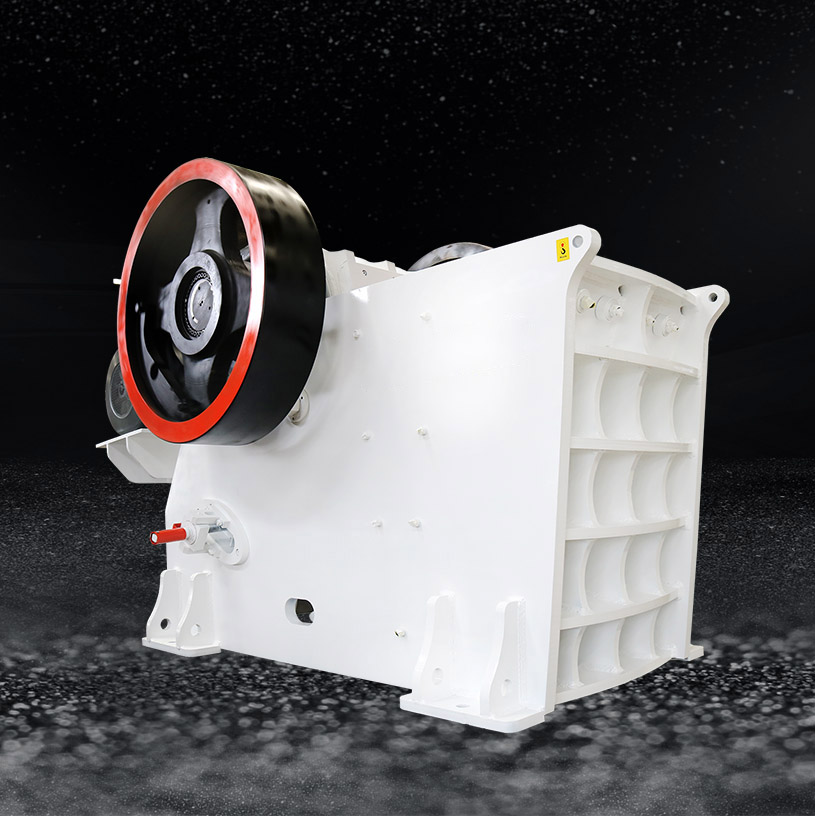

Deep Cavity C series Jaw crusher

Product Introduction:

C series jaw crusher is a crusher that is composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the animal’s jaws to complete the material crushing operation. Through continuous updating and improvement of , the single machine can save 15%-30% energy, and the system energy saving is more than doubled. Using deep cavity crushing, there is no dead zone when crushing, and the feeding and crushing efficiency have been improved.

Product Advantages:

1. Deep cavity crushing, no dead zone, feeding and crushing efficiency have been improved.

2. After the jaw plate is upgraded and optimized, the crushing capacity is improved and the cost is reduced.

3. Compared with the same type of machine, C series jaw crusher can save energy by 15%-30%, and the energy saving of the system is more than doubled.

4. The large stroke of the mailbox at the bottom of the crushing chamber ensures a higher output and a better crushing ratio.

Working Principle:

The crushing cavity is composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the animal’s jaws to complete the material crushing operation. It adopts a curved extrusion type of work. When working, the motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate Approaching the fixed jaw, at the same time, the material is crushed or chopped to achieve the purpose of crushing.

Product Parameters:

Technical parameters of C series jaw crusher

| Model | Feeding port size(mm) | Max feeding size (mm) | Discharge opening range(mm) | Capacity(t/h) | Eccentric shaft speed(r/min) | Power | Weight | Dimension(LxWxH) |

| (kw) | (t) | (mm) | ||||||

| C80 | 510*800 | 420 | 40-175 | 65-380 | 350 | 75 | 9.52 | 2577*1526*1750 |

| C96 | 580*930 | 460 | 60-175 | 120-455 | 330 | 90 | 11.87 | 2880*1755*1460 |

| C100 | 760*1000 | 640 | 70-200 | 150-545 | 260 | 110 | 23.3 | 3670*2420*2490 |

| C106 | 700*1060 | 580 | 70-200 | 155-580 | 280 | 110 | 17.05 | 3320*2030*2005 |

| C110 | 850*1100 | 730 | 70-200 | 190-625 | 230 | 160 | 29.5 | 3770*2385*2730 |

| C116 | 800*1150 | 680 | 70-200 | 170-600 | 260 | 132 | 21.5 | 3600*2400*2730 |

| C125 | 950*1250 | 800 | 100-250 | 290-845 | 220 | 160 | 43.91 | 4100*2800*2980 |

| C140 | 1070*1400 | 920 | 125-250 | 385-945 | 220 | 200 | 54.01 | 4400*3010*3140 |

| C145 | 1100*1400 | 950 | 125-275 | 400-1070 | 220 | 200 | 63.19 | 4600*3110*3410 |

| C160 | 1200*1600 | 1020 | 150-300 | 520-1275 | 220 | 250 | 83.3 | 5900*3700*4280 |

| C200 | 1500*2000 | 1200 | 175-300 | 760-1590 | 200 | 400 | 137.16 | 6700*4040*4465 |