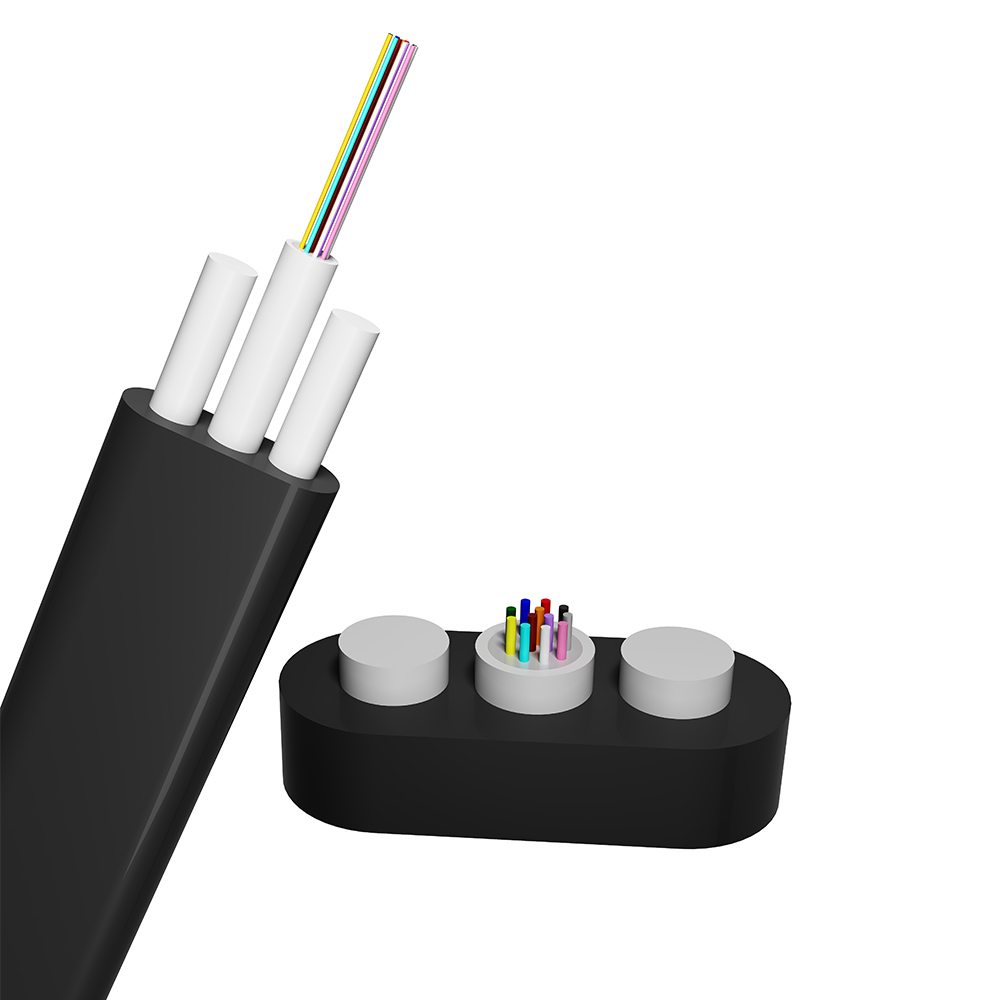

Double FRP reinforced non-metallic central bundle tube cable

Product Features

Accurately controlling the excess length of optical fiber ensures that the optical cable has good tensile performance and temperature characteristics.

Resistant to high and low temperature cycles, resulting in anti-aging and a longer lifespan.

All optical cables have a non-metallic structure, making them lightweight, easy to lay, and providing better anti-electromagnetic and lightning protection effects.

Compared with butterfly optical cables, runway structure products have no risks such as water accumulation, ice coating, and cocoon formation, and have stable optical transmission performance.

Easy stripping shortens the time of external protection and improves construction efficiency.

Optical cables have the advantages of corrosion resistance, ultraviolet protection, and environmental protection.

Optical Characteristics

| Fiber Type | Attenuation | 1310nm MFD(Mode Field Diameter) | Cable Cut-off Wavelength λcc(nm) | |

| @1310nm(dB/KM) | @1550nm(dB/KM) | |||

| G652D | ≤0.36 | ≤0.22 | 9.2±0.4 | ≤1260 |

| G657A1 | ≤0.36 | ≤0.22 | 9.2±0.4 | ≤1260 |

| G657A2 | ≤0.36 | ≤0.22 | 9.2±0.4 | ≤1260 |

| G655 | ≤0.4 | ≤0.23 | (8.0-11)±0.7 | ≤1450 |

| 50/125 | ≤3.5 @850nm | ≤1.5 @1300nm | / | / |

| 62.5/125 | ≤3.5 @850nm | ≤1.5 @1300nm | / | / |

Technical Parameters

| Fiber Count | Cable Diameter (mm) ±0.5 |

Cable Weight (kg/km) |

Tensile Strength (N) | Crush Resistance (N/100mm) | Bend Radius (mm) | |||

| Long Term | Short Term | Long Term | Short Term | Static | Dynamic | |||

| 2-12 | 4.0*8.0 | 35 | 600 | 1500 | 300 | 1000 | 10D | 20D |

Application

FTTX, Access to the building from outside.

Laying Method

Duct, Non self-supporting aerial, Direct buried.

Operating Temperature

| Temperature Range | ||

| Transportation | Installation | Operation |

| -40℃~+70℃ | -20℃~+60℃ | -40℃~+70℃ |

Standard

YD/T 769

Packing And Mark

cables are coiled on bakelite, wooden, or ironwood drums. During transportation, the right tools should be used to avoid damaging the package and to handle them with ease. Cables should be protected from moisture, kept away from high temperatures and fire sparks, protected from over-bending and crushing, and protected from mechanical stress and damage. It is not allowed to have two lengths of cable in one drum, and both ends should be sealed. The two ends should be packed inside the drum, and a reserve length of cable not less than 3 meters should be provided.

The color of cable markings is white. The printing shall be carried out at intervals of 1 meter on the outer sheath of the cable. The legend for the outer sheath marking can be changed according to the user’s requests.

Test report and certification provided.