DP20E Single Punch tablet press machine lab use

product Features

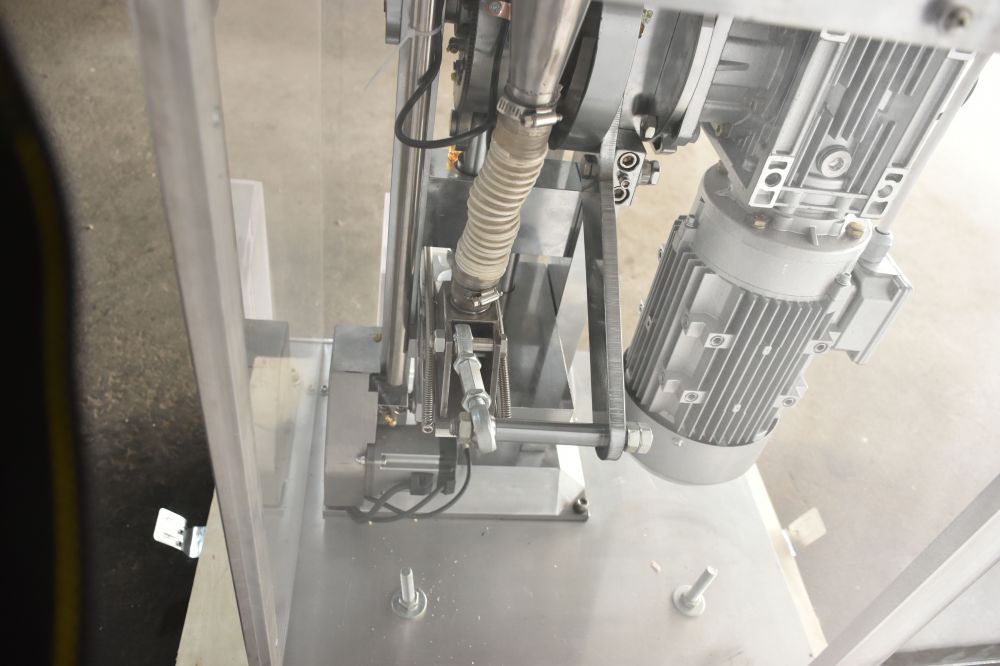

1. Machine with forward jog and reverse jog function.

2. Speed and filling depth can be adjust directly in PLC touch screen.

3. Machine can automatically detect the position of the upper punch die , adjust it to a safe position, and then adjust the filling depth.

4. Production data can be exported through USB interfacce.

5. Servo motor controls regulating speed and powder filling amount.

product description

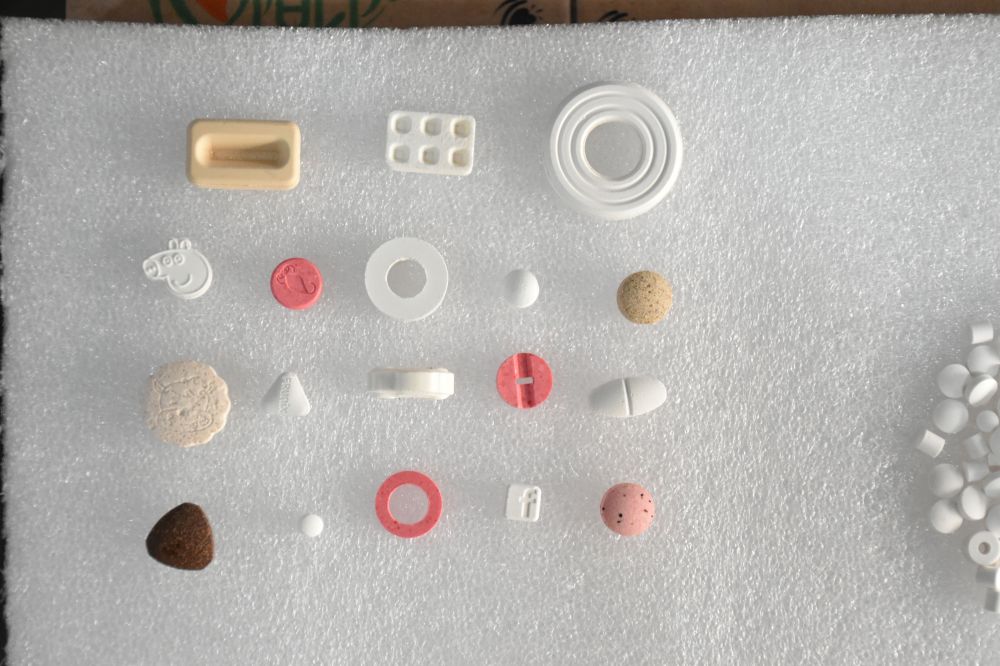

The single punch tablet machine is an impressive piece of equipment that offers versatility and reliability in the pressing of both powder and granular raw materials into tablets. Its adaptability makes it highly sought after in various industries, such as pharmaceuticals, chemicals, and research settings, where the need for efficient tablet production is paramount. The machine’s adjustable features, user-friendly design, and ease of maintenance contribute to its appeal, making it a valuable asset in the manufacturing process.

Furthermore, its compact size and light weight make it a convenient option for small-scale production and laboratory use, allowing for flexibility and ease of movement. This makes it well-suited for research and development settings as well as for small-scale production facilities where space is limited. Overall, the single punch tablet machine offers a reliable and efficient solution for producing a wide range of tablets across different industries, providing a cost-effective and user-friendly option for businesses looking to streamline their tablet production processes. Its ability to cater to diverse production needs while maintaining a high standard of output quality makes it an essential tool for any industry that requires tablet manufacturing capabilities.

Product parameters

|

Type |

DP-20C |

|

Pressure |

60 kn |

|

Max. Diameter of Tablet |

25 mm |

|

Max. Filling Depth |

18 mm |

|

Max. Thickness of Tablet |

8 mm |

|

Capacity |

2100 pcs/h |

|

Power |

1.5 kw |

|

Weight |

180 kg |