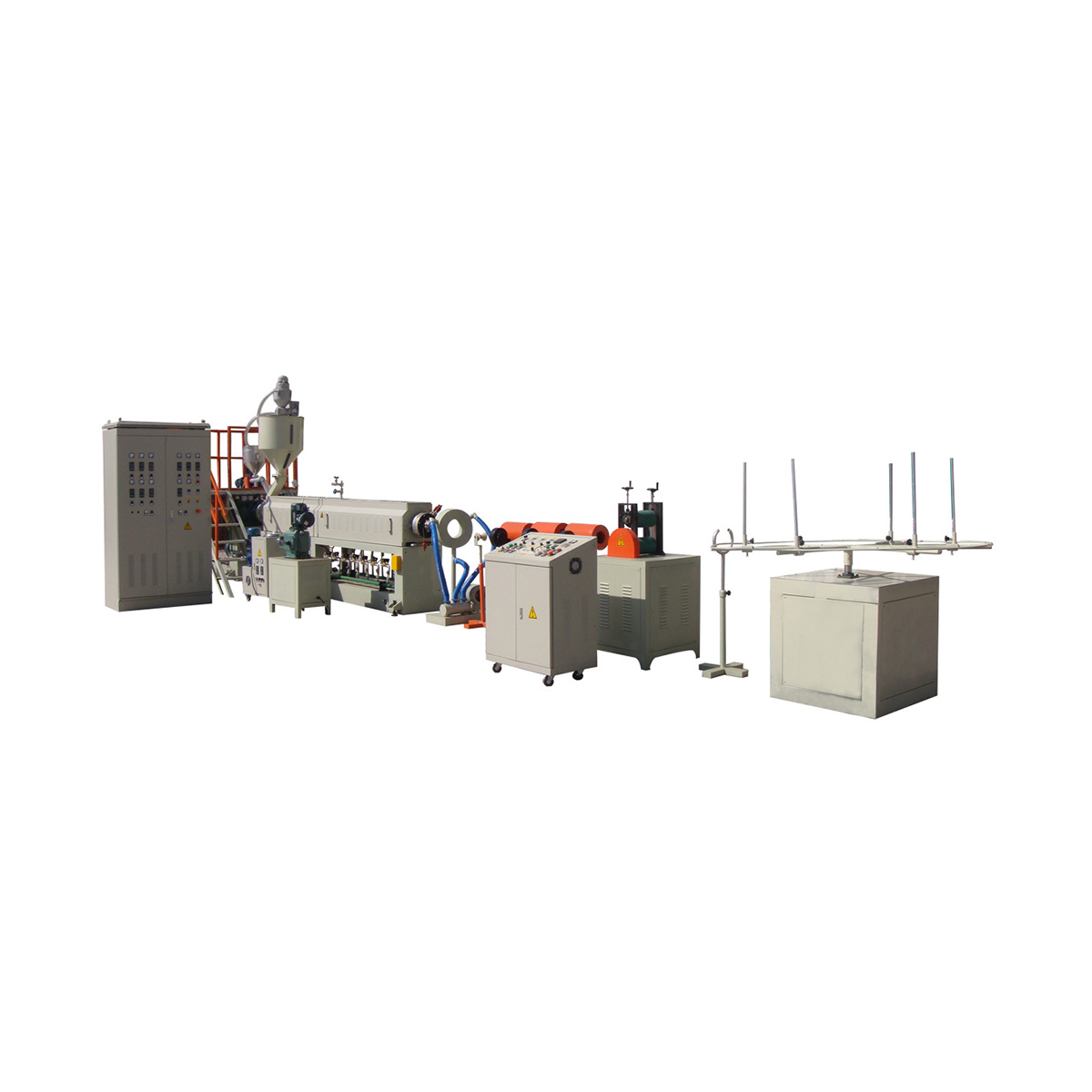

Epe foam pipe rod machine

working process

machine description

Epe foam sheet extruder producing fine closed cell Polyetlene foam sheet, by our unique designed Screw and Barrel system, using Butane foaming agent, Talc powder or Talc master batch and Anti-shrinking agent (GMS for short-Surface Active Agent) by accumulated experience and advanced technology.

Extruder

Gear wheel: SCM4 special gear wheel, Polished and heated

Motor: AC30KW×4P Equipped with the transducer

Method of heating: casted aluminum heater

Method of cooling: cycle water

Material: 38CrMoALA nitriding steel

Heating and cooling system

Material: 38CrMoAl

Heating area: 9 sets

Method of heating: casted aluminum heater

Method of cooling: cycle water

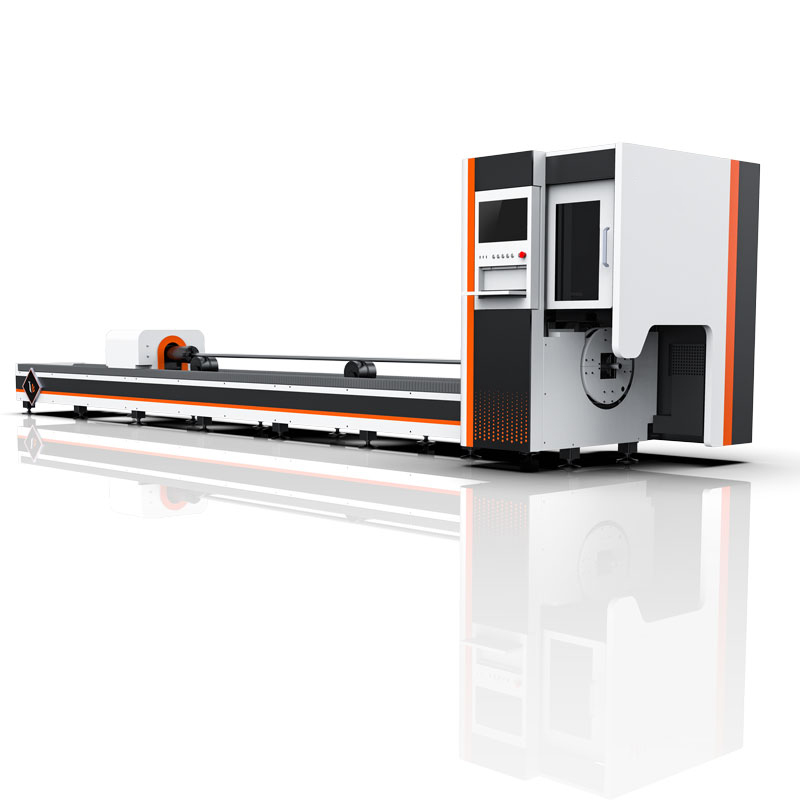

Screen Changer

After the Epe material is plasticized, foreign particles and impurities are filtered out when the plasticized material flows through the filter to reduce the generation of waste and ensure product quality

Head

Type: round mold head for expanding

Material: 38CrMoAl

Heating region: 1 zone

Heating method: electricity heater

Fuse pressure panel: 0-70Mpa

Fuse temperature: T/M detector , 1 detecting site