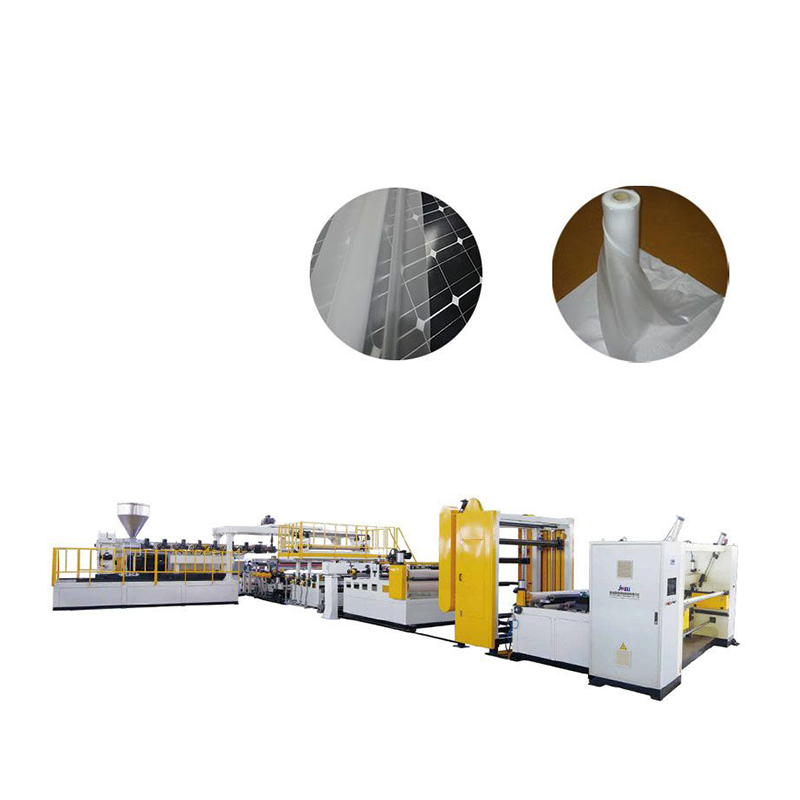

EVA POE Photovoltaic Solar Film Extrusion Line

PRODUCT video

PRODUCT DESCRIPTION

Automatic gravimetric feeding system guarantees variety of solid, liquid additives and raw materials high-precision feeding. Low-temperature extrusion system to ensure adequate mixing in the stable of plasticizing to prevent additives cross-linking. Special design of casting process gives the good solution to roller adhesion. Professional online tempering device to get rid of inner stress. Tension control system ensure the flexible sheets conveying placidly during cooling, pulling and winding process.The on-line thickness measuring and defect inspecting system can provide real-time feedback of the production quality of EVA, POE solar film.

Performance characteristics

Performance characteristics of EVA POE Solar Film Extrusion Line:

1.China eva film extrusion line adopts single screw extrusion for EVA and single screw extrusion for POE. The screw and barrel constant temperature circulating water cooling system solves the technical problems of EVA/POE plasticization and non-crosslinking.

2. The roller body adopts double-sided embossing, which solves the technical difficulty of film sticking to the roller.

3.The cooling part adopts cooling roller and stress-relieving cooling bed, so that the film runs smoothly, the molding is sufficient, and the shrinkage rate is guaranteed to be less than 3%.

4.The whole line of EVA film extrusion line adopts PLC automatic control to realize man-machine interface operation.

5.As an EVA film extrusion line manufacturer, is equipped with an online quality monitoring system to ensure product qualification rate.

6.Patented design micro tension winder, the line speed of the whole machine can reach 18m/min.

PRODUCT details

|

Model |

Extruder type |

Products thickness(mm) |

Max. output |

|

Single extrusion |

JWS160 |

0.2-1.0 |

300-450 |

|

Co-extrusion |

JWS160+WS180 |

0.2-1.0 |

750-850 |

|

Co-extrusion |

JWS180+WS180 |

0.2-1.0 |

800-1000 |

|

Co-extrusion |

JWS180+WS200 |

0.2-1.0 |

900-1100 |

PRODUCT application

EVA film is a thin film product which is made of EVA as the main raw material, added with various modifying additives, fully mixed, heated by the production and processing equipment, cast and extruded. The cured EVA can withstand atmospheric changes and has elasticity. After bonding with the glass, it can improve the transmittance of the glass, play a role in enhancing the transmittance and gain the output of the solar cell module. Therefore, it is an ideal packaging material for solar cell modules and glass.

Write your message here and send it to us